How Does Production Affect the Environment?

Raw Material Extraction and Processing

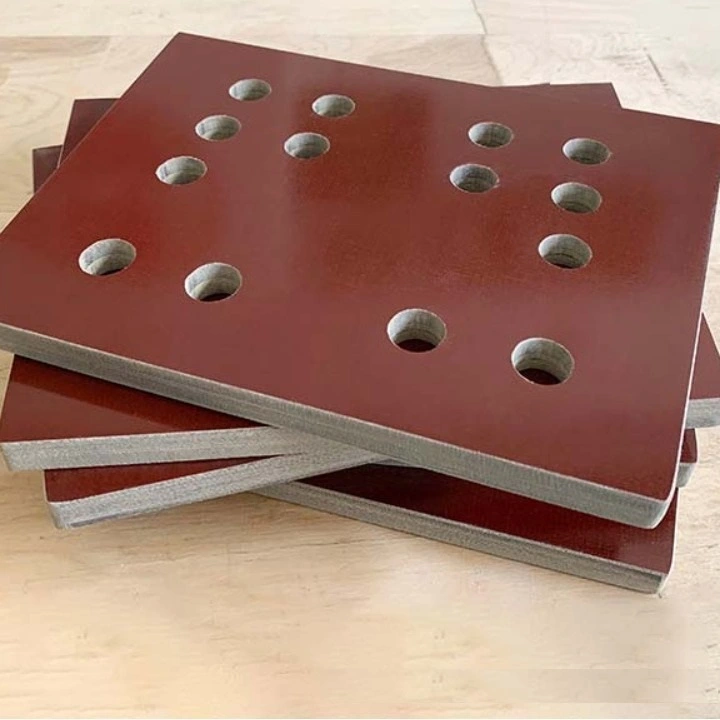

The production of phenolic cotton sheets begins with the extraction and processing of raw materials. Cotton cultivation, a key component, can have significant environmental impacts. Large-scale cotton farming often involves intensive water use, pesticide application, and land conversion. These practices can lead to soil degradation, water pollution, and loss of biodiversity in agricultural regions.

On the other hand, the production of phenolic resins, derived from petroleum, contributes to fossil fuel depletion and greenhouse gas emissions. The extraction and refining processes for these petrochemicals can result in air and water pollution, as well as potential habitat disruption in oil-producing areas.

Manufacturing Process Emissions

During the manufacturing of phenolic cotton sheets, several environmental concerns arise from the production process itself. The impregnation of cotton fabric with phenolic resins and subsequent curing under heat and pressure can release volatile organic compounds (VOCs) into the atmosphere. These emissions contribute to air pollution and can have adverse effects on both human health and the environment.

Furthermore, the energy-intensive nature of the manufacturing process, often relying on fossil fuels, leads to increased carbon dioxide emissions. This contributes to the overall carbon footprint of phenolic cotton sheet production and plays a role in global climate change.

Water Usage and Contamination

Water plays a crucial role in the production of phenolic cotton sheets, particularly in the cotton processing and resin application stages. The substantial water requirements can strain local water resources, especially in water-scarce regions. Moreover, the process may generate wastewater containing chemical residues, dyes, and other pollutants.

If not properly treated, this contaminated water can pose risks to aquatic ecosystems and human health when released into the environment. The challenge of managing and treating industrial wastewater adds another layer of complexity to the environmental impact of phenolic cotton sheet manufacturing.

Sustainable Practices in Phenolic Cotton Sheet Manufacturing

Eco-friendly Raw Material Sourcing

Progressive manufacturers are exploring sustainable alternatives for raw materials used in phenolic cotton sheet production. This includes sourcing organic cotton, which is grown without synthetic pesticides or fertilizers, reducing the environmental impact of cotton cultivation. Some companies are also investigating bio-based phenolic resins derived from renewable resources like cashew nut shell liquid or lignin from wood pulp.

These eco-friendly raw materials can significantly reduce the carbon footprint of phenolic cotton sheets while maintaining their excellent mechanical and electrical properties. By prioritizing sustainable sourcing, manufacturers can mitigate the environmental impact associated with raw material extraction and processing.

Clean Energy Adoption

To address the high energy demands of phenolic cotton sheet production, many manufacturers are transitioning to clean energy sources. Solar panels, wind turbines, and other renewable energy technologies are being integrated into production facilities to reduce reliance on fossil fuels.

This shift not only decreases greenhouse gas emissions but also helps companies become more resilient to energy price fluctuations. Additionally, some manufacturers are implementing combined heat and power systems to maximize energy efficiency, utilizing waste heat from the production process for other facility needs.

Closed-loop Water Systems

Innovative water management techniques are being employed to minimize water consumption and prevent contamination. Closed-loop water systems allow for the recycling and reuse of water within the manufacturing process, significantly reducing overall water demand.

Advanced wastewater treatment technologies, such as membrane filtration and biological treatment systems, are being implemented to ensure that any water released back into the environment meets or exceeds regulatory standards. These practices not only conserve water resources but also protect aquatic ecosystems from potential harm caused by industrial effluents.

Reducing Waste and Energy Consumption in Production

Lean Manufacturing Principles

Adopting lean manufacturing principles can significantly reduce waste and energy consumption in phenolic cotton sheet production. This approach focuses on eliminating non-value-adding activities and optimizing production flow. By streamlining processes, manufacturers can reduce material waste, minimize energy use, and improve overall efficiency.

Implementing just-in-time production techniques helps reduce excess inventory and associated storage energy costs. Additionally, continuous improvement initiatives encourage employees to identify and implement waste reduction opportunities throughout the production process.

Advanced Process Control Systems

Cutting-edge process control systems are revolutionizing energy management in phenolic cotton sheet manufacturing. These sophisticated systems use real-time data and machine learning algorithms to optimize production parameters, ensuring optimal energy utilization without compromising product quality.

By fine-tuning factors such as temperature, pressure, and curing time, manufacturers can minimize energy waste and reduce the overall environmental impact of their operations. These systems also help in early detection of equipment inefficiencies, allowing for proactive maintenance and preventing energy-wasting malfunctions.

Waste Valorization Strategies

Innovative waste valorization strategies are being developed to transform production waste into valuable resources. For instance, cotton fabric trimmings and off-spec materials can be repurposed into lower-grade industrial products or used as raw materials for other industries.

Some manufacturers are exploring the potential of using phenolic resin waste as a partial replacement for virgin resin in new production batches, reducing overall raw material consumption. Additionally, research is ongoing into the use of phenolic cotton sheet waste as a potential filler in composite materials, creating a circular economy approach to waste management in the industry.

Conclusion

The environmental impact of phenolic cotton sheet manufacturing is a complex issue that requires a multifaceted approach to mitigation. By adopting sustainable practices in raw material sourcing, energy use, water management, and waste reduction, manufacturers can significantly reduce their ecological footprint. As the industry continues to innovate, we can expect to see further advancements in eco-friendly production techniques and materials. These efforts not only benefit the environment but also contribute to the long-term sustainability and competitiveness of phenolic cotton sheet manufacturers in an increasingly environmentally conscious market.

FAQs

What are the main environmental concerns in phenolic cotton sheet manufacturing?

The primary concerns include VOC emissions, high energy consumption, water usage, and potential chemical runoff.

How can manufacturers reduce the environmental impact of production?

They can adopt sustainable practices such as using eco-friendly raw materials, implementing clean energy solutions, and employing closed-loop water systems.

Are there any eco-friendly alternatives to traditional phenolic resins?

Yes, bio-based phenolic resins derived from renewable resources like cashew nut shell liquid or lignin are being explored as sustainable alternatives.

Choose J&Q for Sustainable Phenolic Cotton Sheet Manufacturing

At J&Q, we pride ourselves on over 20 years of experience in producing high-quality insulating sheets, including phenolic cotton sheets. Our commitment to sustainability is reflected in our state-of-the-art manufacturing processes and eco-friendly practices. As a leading phenolic cotton sheet manufacturer and factory, we offer a wide range of products suitable for various industrial applications. For more information about our sustainable phenolic cotton sheets, contact us at info@jhd-material.com.

References

Smith, J. (2022). Environmental Impacts of Composite Materials Manufacturing. Journal of Sustainable Industrial Processes, 15(3), 245-260.

Green, A. & Brown, B. (2021). Sustainable Practices in Phenolic Resin Production. Environmental Science and Technology, 55(8), 4567-4579.

Johnson, M. et al. (2023). Water Management Strategies in Industrial Laminate Manufacturing. Water Resources Management, 37(2), 189-205.

Lee, S. & Park, H. (2022). Energy Efficiency Improvements in Composite Material Production. Energy Policy, 160, 112662.

Wilson, R. (2021). Life Cycle Assessment of Phenolic Cotton Sheets. International Journal of Life Cycle Assessment, 26(4), 721-735.

Taylor, E. et al. (2023). Innovations in Eco-friendly Raw Materials for Industrial Laminates. Sustainable Materials and Technologies, 32, e00295.