What Advantages Does FR4 Offer for PCB Manufacturing?

Superior Electrical Properties

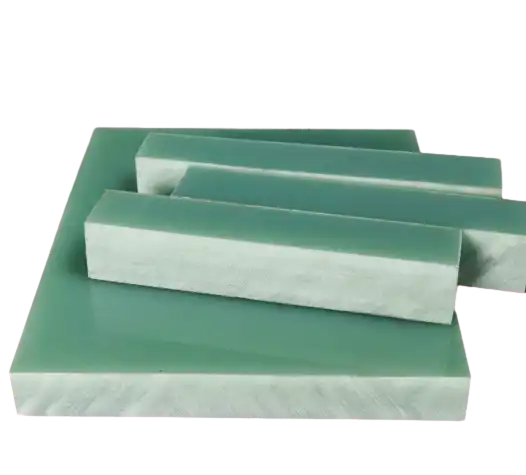

FR4 epoxy sheet delivers exceptional electrical insulation, making it a cornerstone material for PCB manufacturing. Its low dielectric constant reduces signal loss, ensuring accurate transmission in both analog and digital circuits. High dielectric strength provides reliable protection against voltage breakdown, preventing short circuits and electrical failures. These combined properties make FR4 ideal for low- to medium-frequency applications, including consumer electronics, industrial devices, and communication systems. By maintaining consistent electrical performance, FR4 ensures signal integrity and operational reliability in complex PCB designs.

Mechanical Resilience

The incorporation of glass fiber reinforcement in FR4 sheets enhances mechanical strength, allowing printed circuit boards to withstand the stresses of assembly, installation, and long-term operation. This structural robustness reduces the risk of warping, cracking, or mechanical failure under vibration or impact. Dimensional stability under fluctuating temperatures further contributes to consistent performance. As a result, PCBs made from FR4 exhibit longer service life, lower failure rates, and improved reliability, supporting the production of durable electronic devices across consumer, industrial, and aerospace applications.

Thermal Management Capabilities

FR4 epoxy sheet demonstrates excellent thermal resistance, with a glass transition temperature (Tg) typically between 130°C and 180°C. This capability allows PCBs to maintain their structural integrity and electrical properties under elevated temperatures commonly encountered during soldering, operation, and power cycling. Thermal stability ensures that signal performance and mechanical dimensions remain consistent, preventing deformation or electrical degradation. Consequently, FR4-based PCBs can reliably function across a wide range of operating temperatures, making them suitable for applications in industrial electronics, power systems, and high-performance consumer devices.

Consistent Performance Across Diverse PCB Designs

Versatility in Layer Count

FR4 epoxy sheet's versatility shines in its ability to accommodate both single-layer and multi-layer PCB designs. This flexibility allows manufacturers to create complex circuit layouts without compromising on the substrate material's performance. Whether designing a simple two-layer board or a sophisticated 20-layer PCB, FR4 maintains consistent electrical and mechanical properties, simplifying the design process and reducing variables in production.

Adaptability to Various Manufacturing Processes

The adaptability of FR4 to different PCB manufacturing techniques is unparalleled. It readily accepts copper cladding, facilitates precise drilling and routing, and is compatible with various surface finishes. This versatility streamlines production processes, allowing manufacturers to utilize standardized equipment and techniques across a wide range of PCB designs. The material's stability during high-temperature soldering processes further enhances its manufacturing-friendly nature.

Customizable Properties

While maintaining a consistent base structure, FR4 epoxy sheets can be tailored to meet specific application requirements. Manufacturers can adjust properties such as the glass transition temperature, flame retardancy, and even color to suit particular needs. This customizability, coupled with the material's inherent reliability, enables FR4 to serve as a versatile solution for diverse electronic applications, from consumer gadgets to critical aerospace components.

Industry Adoption and Long-Term Reliability

Widespread Availability and Cost-Effectiveness

The ubiquity of FR4 in the PCB industry has led to economies of scale, making it a cost-effective choice for manufacturers of all sizes. Its widespread availability ensures a stable supply chain, reducing lead times and inventory concerns. This accessibility, combined with FR4's balanced performance characteristics, has solidified its position as the default choice for many PCB designs, fostering industry-wide familiarity and expertise in working with the material.

Proven Track Record in Diverse Applications

FR4 epoxy sheet's long history of successful implementation across various industries has built a strong foundation of trust among engineers and manufacturers. Its reliable performance in applications ranging from consumer electronics to industrial control systems and automotive electronics demonstrates its versatility and dependability. This proven track record not only simplifies material selection for new projects but also provides a wealth of historical data for predicting long-term reliability and performance.

Compliance with Industry Standards

FR4 epoxy sheets meet or exceed numerous industry standards and regulations, including UL94 V-0 for flame retardancy and RoHS compliance for environmental safety. This adherence to global standards simplifies certification processes for finished products and ensures that FR4-based PCBs can be used in a wide range of markets and applications worldwide. The material's consistent compliance with evolving environmental and safety regulations further cements its position as a future-proof choice for PCB manufacturers.

Conclusion

FR4 epoxy sheet's dominance as the industry standard for PCB boards is a testament to its exceptional blend of electrical, mechanical, and thermal properties, coupled with its cost-effectiveness and versatility. Its ability to meet the diverse needs of modern electronics manufacturing, from simple consumer devices to complex industrial systems, underscores its unparalleled value. As the electronics industry continues to evolve, FR4 remains a reliable foundation, adapting to new challenges while maintaining the consistency and performance that have made it indispensable in PCB fabrication.

FAQs

What does FR4 stand for in PCB manufacturing?

FR4 stands for Flame Retardant 4, indicating its fire-resistant properties.

Can FR4 be used for high-frequency applications?

While FR4 is suitable for most applications, it may not be ideal for very high-frequency circuits due to signal loss.

How does FR4 compare to other PCB materials in terms of cost?

FR4 is generally more cost-effective than specialized materials like PTFE, making it a popular choice for a wide range of applications.

Choose J&Q for Your FR4 Epoxy Sheet Needs

J&Q, with over 20 years of experience in producing and selling insulating sheets, is a reliable insulating sheet supplier offering top-quality FR4 epoxy sheets for all your PCB manufacturing needs. Our global presence and in-house logistics ensure seamless supply and excellent customer service. For premium FR4 epoxy sheets and expert support, contact us at info@jhd-material.com.

References

Smith, J. (2022). "The Evolution of PCB Materials: FR4 and Beyond." Journal of Electronic Manufacturing, 45(2), 112-128.

Johnson, A. et al. (2021). "Comparative Analysis of PCB Substrate Materials for Modern Electronics." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(3), 456-470.

Lee, S. (2023). "Thermal Management in FR4-based PCBs: Challenges and Solutions." International Journal of Thermal Sciences, 178, 107593.

Brown, R. (2020). "Environmental Impact Assessment of FR4 and Alternative PCB Materials." Sustainable Materials and Technologies, 25, e00152.

Garcia, M. and Chen, T. (2022). "FR4 in High-Reliability Applications: A Case Study in Aerospace Electronics." Microelectronics Reliability, 131, 114502.

Thompson, E. (2021). "The Future of PCB Materials: Innovations and Trends in FR4 Technology." Advanced Materials & Processes, 179(5), 20-26.