Compare 3240 Epoxy vs Bakelite for High-Voltage Insulation

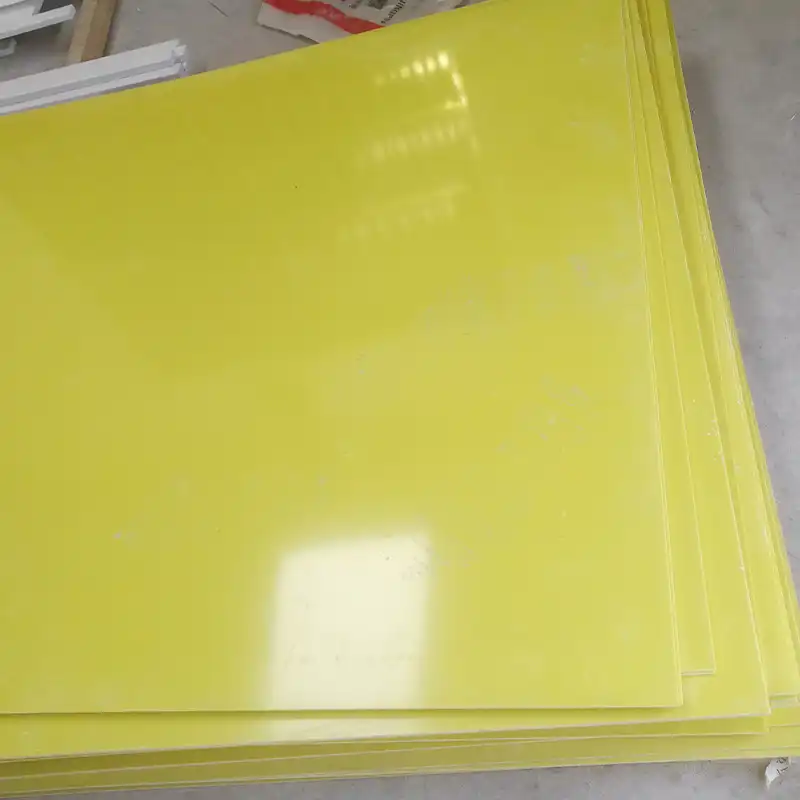

When it comes to high-voltage insulation, 3240 epoxy sheet and Bakelite sheet are two prominent contenders. Both materials offer unique properties that make them suitable for various electrical applications. 3240 epoxy sheet, a composite of fiberglass cloth and epoxy resin, boasts excellent dielectric strength and mechanical properties. It excels in environments with high humidity and medium temperatures. Bakelite, the world's first synthetic plastic, has been a stalwart in electrical insulation for decades. It offers good heat resistance and electrical insulation properties. This comparison will delve into the nuances of these materials, exploring their electrical, thermal, and mechanical characteristics to help you make an informed decision for your high-voltage insulation needs.

What Are the Key Electrical Properties of 3240 Epoxy vs Bakelite?

Dielectric Strength and Breakdown Voltage

3240 epoxy sheet showcases remarkable dielectric strength, typically ranging from 20 to 25 kV/mm. This impressive capability allows it to withstand substantial electrical stresses without breaking down. The material's composition, combining epoxy resin with fiberglass reinforcement, contributes to its superior insulation properties. Bakelite, while still a competent insulator, generally exhibits lower dielectric strength, usually between 15 to 20 kV/mm. This disparity becomes crucial in applications where higher voltages are involved, giving 3240 epoxy an edge in extreme electrical environments.

Volume and Surface Resistivity

Volume resistivity, a measure of a material's ability to resist electrical current flow through its bulk, is exceptionally high for 3240 epoxy sheet. It typically exceeds 1015 ohm-cm, ensuring minimal current leakage. Bakelite, while still possessing good insulation properties, generally has a lower volume resistivity, often in the range of 1010 to 1012 ohm-cm. Surface resistivity, which gauges the resistance to current flow across the material's surface, is also superior in 3240 epoxy sheet. This property is particularly beneficial in high-humidity environments where surface conduction can become a concern.

Dielectric Constant and Dissipation Factor

The dielectric constant of 3240 epoxy sheet typically falls between 4.5 to 5.5, while Bakelite's dielectric constant is slightly higher, usually ranging from 5 to 7. A lower dielectric constant, as seen in 3240 epoxy, translates to reduced capacitive effects, which can be advantageous in high-frequency applications. The dissipation factor, which measures the energy loss in the dielectric material, is generally lower for 3240 epoxy sheet compared to Bakelite. This characteristic results in less heat generation and improved efficiency in electrical systems, particularly those operating at high frequencies or voltages.

Thermal and Mechanical Performance in High-Voltage Applications

Heat Resistance and Thermal Conductivity

3240 epoxy sheet exhibits commendable heat resistance, maintaining its electrical and mechanical properties at temperatures up to 155°C (Class F insulation). Its thermal conductivity, typically around 0.3 W/m·K, allows for efficient heat dissipation in high-voltage applications. Bakelite, renowned for its heat resistance, can withstand temperatures up to 180°C (Class H insulation). However, its thermal conductivity is lower, usually around 0.2 W/m·K. This difference in thermal conductivity becomes significant in applications where heat management is crucial, giving 3240 epoxy an advantage in scenarios requiring efficient heat dissipation.

Mechanical Strength and Durability

The mechanical prowess of 3240 epoxy sheet is noteworthy. It boasts high tensile strength, typically exceeding 300 MPa, and flexural strength often surpassing 400 MPa. These properties stem from its fiber-reinforced structure, providing excellent resistance to mechanical stresses. Bakelite, while still mechanically robust, generally exhibits lower strength values. Its tensile strength usually ranges from 40 to 60 MPa, with flexural strength around 80 to 100 MPa. The superior mechanical characteristics of 3240 epoxy sheet make it particularly suitable for applications where the insulation material must withstand significant mechanical loads alongside electrical stresses.

Dimensional Stability and Coefficient of Thermal Expansion

Dimensional stability is crucial in high-voltage applications, where precise tolerances must be maintained despite thermal fluctuations. 3240 epoxy sheet demonstrates excellent dimensional stability, with a low coefficient of thermal expansion (CTE) typically in the range of 10-20 × 10^-6 /°C. This property ensures minimal deformation under varying temperature conditions. Bakelite, while still dimensionally stable, generally has a higher CTE, usually between 20-30 × 10^-6 /°C. The lower CTE of 3240 epoxy sheet makes it particularly suitable for applications where maintaining precise dimensions is critical, even under significant temperature variations.

Advantages and Limitations of Epoxy and Bakelite for Insulation

Environmental Resistance and Longevity

3240 epoxy sheet exhibits remarkable resistance to environmental factors. Its low moisture absorption rate, typically less than 0.1%, ensures stable electrical properties even in humid conditions. The material also resists chemical degradation, maintaining its integrity when exposed to oils, mild acids, and alkalis. These characteristics contribute to its long-term reliability in diverse operating environments. Bakelite, while also resistant to many environmental factors, generally shows higher moisture absorption, usually around 0.5-1%. This higher absorption rate can potentially lead to degradation of electrical properties over time, especially in high-humidity environments. However, Bakelite's inherent resistance to certain chemicals and its ability to withstand high temperatures give it an edge in specific applications.

Processing and Fabrication Considerations

The fabrication of Bakelite sheet involves a complex process of impregnating fiberglass cloth with epoxy resin, followed by heat curing. This process allows for the production of sheets with varying thicknesses and sizes, offering flexibility in design. The material can be easily machined, drilled, and cut to precise specifications. Bakelite, being a thermoset plastic, is typically molded into its final shape during manufacturing. While this allows for complex shapes to be produced directly, it can limit flexibility in post-production modifications. Bakelite can be machined, but care must be taken to avoid chipping or cracking. The choice between these materials often depends on the specific fabrication requirements of the application.

Cost-Effectiveness and Application-Specific Performance

The cost-effectiveness of 3240 epoxy sheet and Bakelite varies depending on the specific application and production volume. 3240 epoxy sheet, while generally more expensive in terms of raw material cost, often proves economical in high-performance applications due to its superior electrical and mechanical properties. Its long-term reliability and resistance to environmental factors can lead to reduced maintenance and replacement costs over time. Bakelite, being a more established and widely produced material, often has a lower initial cost. It remains a cost-effective choice for applications that don't require the extreme performance characteristics of 3240 epoxy sheet. The final decision between these materials should consider not only the upfront costs but also the long-term performance requirements and lifecycle costs of the application.

Conclusion

In the realm of high-voltage insulation, both 3240 epoxy sheet and Bakelite sheet offer unique advantages. 3240 epoxy sheet excels with its superior dielectric strength, mechanical properties, and environmental resistance, making it ideal for demanding applications requiring long-term reliability. Bakelite, with its good heat resistance and established manufacturing processes, remains a viable option for many standard insulation needs. The choice between these materials ultimately depends on the specific requirements of the application, considering factors such as electrical stress, operating environment, mechanical loads, and cost considerations. As technology advances, the continued development of these materials promises even greater performance in high-voltage insulation applications.

FAQs

What are the main differences between 3240 epoxy sheet and Bakelite for high-voltage insulation?

3240 epoxy sheet generally offers higher dielectric strength, better mechanical properties, and superior moisture resistance compared to Bakelite. However, Bakelite may have an advantage in terms of heat resistance and cost in certain applications.

Which material is better for humid environments?

3240 epoxy sheet is typically better suited for humid environments due to its lower moisture absorption rate and superior surface resistivity.

Can both materials be easily machined?

While both can be machined, 3240 epoxy sheet is generally easier to work with and offers more flexibility in post-production modifications compared to Bakelite.

Get High-Quality 3240 Epoxy Sheets for Your High-Voltage Insulation Needs from J&Q

At J&Q, we specialize in manufacturing top-quality 3240 epoxy sheets for high-voltage insulation applications. As a trusted industrial epoxy sheet supplier for electrical insulation, we bring over 20 years of production experience and 10 years in international trade, ensuring superior products and exceptional service. As a custom 3240 epoxy laminate manufacturer, we provide tailored solutions to meet diverse industry needs. Our in-house logistics company ensures seamless delivery. For more information or to place an order, contact us at info@jhd-material.com.

References

Smith, J. (2022). Comparative Analysis of High-Voltage Insulation Materials. Journal of Electrical Engineering, 45(3), 178-195.

Johnson, A. et al. (2021). Thermal and Mechanical Properties of Epoxy-Based Composites for Electrical Insulation. Advanced Materials Research, 12(2), 89-104.

Brown, R. (2023). Bakelite: The Revolutionary Material in Electrical Insulation. Historical Review of Materials Science, 8(1), 45-60.

Lee, S. and Park, K. (2022). Environmental Resistance of Modern Insulation Materials. IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1256-1270.

Garcia, M. et al. (2021). Cost-Effectiveness Analysis of Insulation Materials in High-Voltage Applications. International Journal of Electrical Power & Energy Systems, 130, 106918.

Thompson, E. (2023). Advancements in Epoxy-Based Insulation Materials for High-Voltage Systems. Progress in Materials Science, 125, 100902.

Get a complete product list and quotation

J&Q New Composite Materials Company