CNC Machined G11 Parts for Electrical Equipment

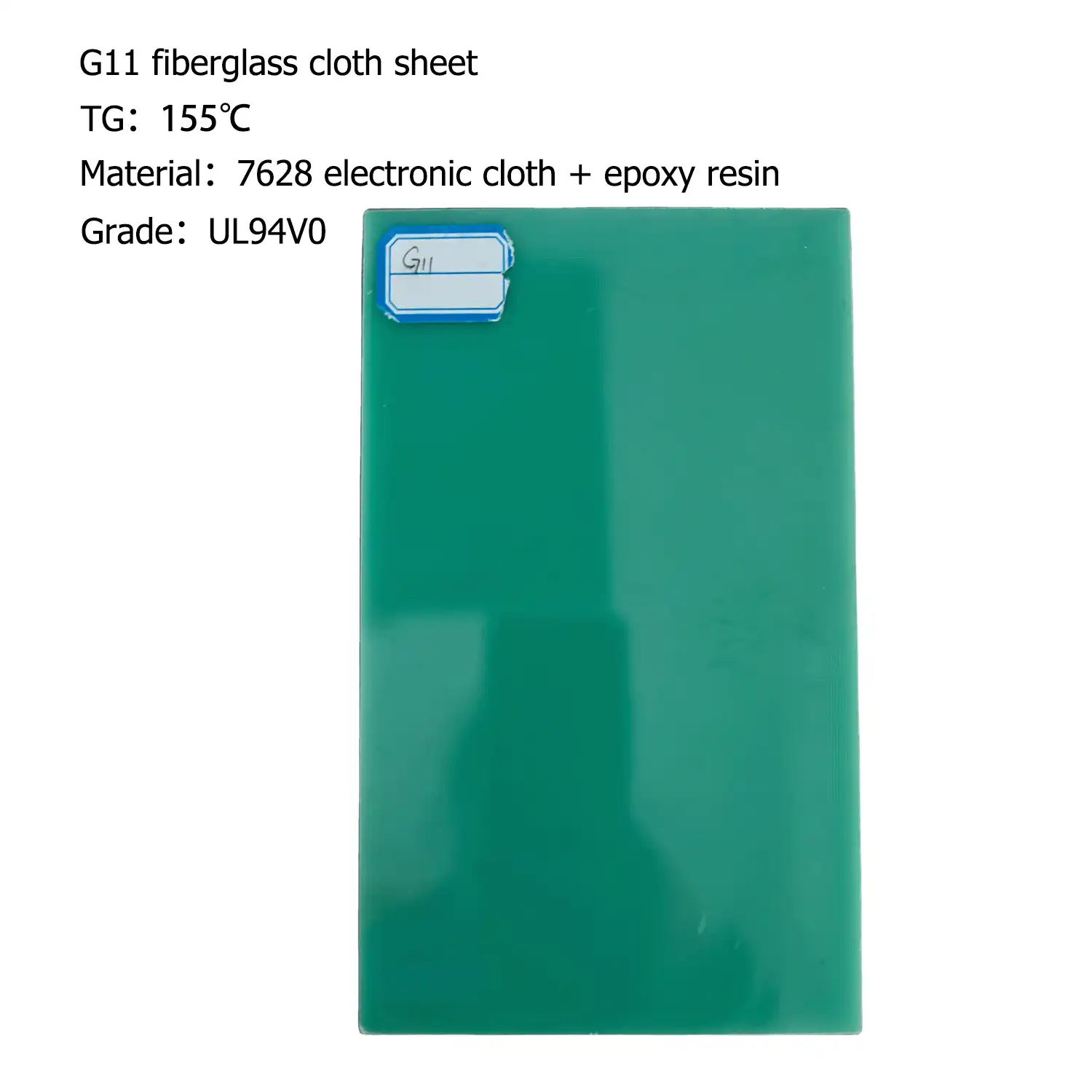

CNC made G11 parts are an important part option for making electrical devices because they offer great electrical insulation qualities along with great mechanical strength. When making a G11 part, high-performance fiberglass epoxy laminate materials that work reliably in tough electrical uses are machined with great care. These parts are very important for transformers, switches, insulators, and other electrical systems that need to have regular insulating qualities and accurate measurements for safety and efficiency.

Understanding CNC Machined G11 Parts in Electrical Equipment

The better electrical protection properties of G11 material make it an absolute must-have for demanding electrical uses. The material's dielectric strength stays the same even when the temperature changes, and it doesn't absorb water or break down chemically. These features make sure that the protection works well throughout the lifetime of the part, which lowers the risk of electricity problems and safety risks.

Material Properties and Performance Characteristics

G11 is very strong and can hold a lot of weight. It is also very resistant to mechanical stress. The braided glass support structure evenly spreads the weight, and the epoxy material keeps the structure's shape even when the weather changes. The ability of G11 components to resist heat means that they can work efficiently in hot settings without affecting their electrical or structural integrity.

CNC machining is very accurate because the cutting processes are handled by a computer, so the dimensions stay the same from one production run to the next. Milling is used for surfaces with complicated shapes, drilling is used to find exact hole locations and sizes, and turning is used for cylinder parts that need to be made with tight tolerances. Quality assurance tools keep an eye on every step of the cutting process to make sure that the parts meet the standards.

Applications in Electrical Equipment

In transformer uses where electrical separation and mechanical safety are important, G11 components are used for insulation walls, support structures, and mounting tools. The dielectric features of the material keep electricity from breaking down, and its mechanical strength lets heavy transformer parts stay in place. G11 parts are used to make spark shields, insulation panels, and structure supports that keep the electricity safe during switching operations.

As structural parts, G11 components are used in insulator systems to provide both electrical insulation and mechanical support. It's important for these uses that the materials don't move, keep their shape under electrical stress, and work reliably for a long time outside. The material's ability to fight UV rays and natural contamination makes it last longer in tough working conditions.

How to Choose the Right CNC Machined G11 Parts for Your Electrical Equipment?

To choose the right G11 sheets, you need to follow an organized process that starts with figuring out the unique practical needs of the electrical application. Calculations of mechanical loads tell us what strength characteristics we need, and shielding needs tell us what insulating properties we need. Material choice and design requirements are affected by the expected service life, operating temperature ranges, and the surroundings.

Establishing Selection Criteria

Dimensional precision standards that make sure electrical parts fit and work right are important selection measures. The specs for the surface finish affect both how well it works electrically and how well it works with other things. Compliance approvals make sure that parts meet industry standards and government rules for use in electrical equipment.

Tolerance ranges have a direct effect on how parts work and how they are put together. Tighter margins make production more expensive, but they may be needed in important situations where accuracy in measurements affects performance. Evaluation of production capacity makes sure that providers can meet supply dates and number needs throughout the lifecycle of the project.

Supplier Evaluation Process

To figure out what a seller can do, you have to look at their machining tools, quality control methods, and professional know-how. Suppliers who have more modern CNC tools can get better surface finish quality and accuracy of measurements. Quality management systems show that you are committed to uniform output standards and methods for growth all the time.

Prototyping services let you check that the designs of parts work before they are made on a large scale. During this testing process, possible problems are found, and the design can be tweaked to make it work better or cost less to make. Long-term relationship growth lowers risks in the supply chain and lets people work together to make changes that help everyone while making sure there is a steady supply of parts.

Common Challenges with CNC Machined G11 Parts and How to Overcome Them

Precision in manufacturing G11 parts have a lot of technical issues that need to be carefully thought out when it comes to cutting settings and process control. When internal pressures build up during cutting, especially with thin-wall pieces or complicated shapes, the metal will warp. During cutting, keeping the temperature under control and using the right handling methods for the work keep stress concentration and structural damage to a minimum.

Root Cause Analysis of Manufacturing Issues

Delamination is a major failure mode in which the glass cloth breaks from the epoxy matrix because the cutting speeds were too slow, too much heat was made, or the wrong tools were used. Cutting tools that are sharp and have the right shape lower the cutting forces and heat buildup that can damage the structure of the material. During cutting processes, coolant devices keep temperatures stable.

Surface flaws like fiber pullout, resin smearing, and edge chipping make the product look bad and make it less effective electrically. Monitoring tool wear makes sure that the cutting edges stay sharp during production runs. Feed rates, tool speeds, and depth of cut are some of the machining factors that need to be optimized for each shape and tolerance.

Best Practices for Quality Improvement

Material handling methods keep G11 sheets from getting damaged while they are being stored or set up. When support systems are set up correctly, they stop bending or shaking that can lead to errors in measurements or surface flaws. Controls for the environment keep the temperature and humidity at steady levels that affect how stable materials are and how well they work when they are machined.

For providers and clients to work together well, they need to talk to each other regularly about design needs, processing skills, and quality standards. Joint problem-solving methods find the reasons of quality problems and come up with good answers. Writing down what was learned leads to knowledge bases that make future production runs better and cut down on problems that keep happening.

Advantages of CNC Machined G11 Parts Over Traditional Alternatives

When it comes to performance, CNC machining is much better than molding or casting when it comes to shielding parts. Precision skills allow for measurement tolerances that can't always be kept by casting processes, especially for uses with complex shapes or tight tolerances. This accuracy cuts down on the time it takes to put together electrical equipment and makes it fit and work better.

Performance Comparison Analysis

Material consistency is better in made parts because the process of making them doesn't change the qualities of the base material. When you mold something, you might add holes, changes in density, or contamination that hurts the electrical or mechanical performance. Machined parts have qualities that stay the same throughout the whole part, so they will behave in a reliable way when they are used.

When it comes to small to medium numbers or special designs, CNC made parts often have longer production times than molded ones. Machining gets rid of the wait times needed to make molds and tools, and it lets you make prototypes quickly or make changes to designs. This gives new ideas for electrical tools shorter development processes and a faster time to market.

Cost-Quality Trade-off Considerations

When there are no mold release agents, gate marks, or other molding artifacts that can affect surface quality, the electrical protection works better. Machined surfaces have stable insulating qualities and don't track or get dirty easily. One benefit of mechanical strength is that it gets rid of weld lines or flow marks that cause stress to gather in plastic parts.

Because customization is so flexible, machined parts can have features that would be hard or impossible to make. It is possible to machine directly without having to put the parts together, even if the internal shapes are complicated or the wall widths change. Scalable production means that the same methods and quality standards can be used for both small batches of prototypes and large production runs.

Trends and Future Developments in CNC Machining of G11 Parts

One problem with production right now is that the material is fragile and needs to be handled carefully and machined in a certain way. Standard cutting speeds may be limited by heat buildup and tool wear, which can make high-volume production less efficient. Because of these limitations, more advanced machine techniques and tools technologies have been created.

Emerging Technology Integration

More advanced manufacturing systems have finishes and shapes that are specially made for G11 sheets. Diamond coating on tools makes them last longer, give the surface a better finish, and lower the cutting forces and heat that are produced. Ultrasonic-assisted machining techniques reduce cutting forces and improve surface quality for difficult-to-machine geometries.

Automation systems let factories run without lights, which improves regularity and cuts down on labor costs. Working with workpieces safely while keeping them in the right place for cutting processes is possible with robotic loading systems. Real-time tracking systems keep an eye on cutting forces, tool wear, and the accuracy of measurements so that process parameters can be improved and repair needs can be predicted.

Industry Evolution and Adaptation Strategies

Improving the speed of manufacturing means cutting down on run times while keeping quality standards high. High-speed machining methods find the best cutting settings for different G11 grades and part shapes. CAD/CAM systems that work together make programming easier and setup times shorter for complicated parts or designs that change often.

Recycling programs for machine trash and energy-efficient production methods are being made because of concerns about the environment. Adapting buying tactics to take advantage of these technology breakthroughs is good for procurement teams. Partnering with suppliers to invest in new skills gives you a competitive edge by raising quality, lowering costs, and making service better.

J&Q: Your Trusted Partner for Custom G11 Components

J&Q specializes in CNC machining of unique G11 parts that are made to work with electrical equipment. We have a lot of experience, with more than twenty years of making insulation materials and more than ten years of trading with other countries. Because we have so much experience, we can understand the special needs of companies that make electrical tools and offer solutions that meet those needs.

Product Range and Capabilities

As part of our product line, we offer development services to make sure the design works, batch production for standard parts, and the creation of complex parts for unique uses. We keep up-to-date CNC machining centers that are fully equipped with the newest technology for making G11 parts precisely, with tight tolerances and excellent surface finishes. Quality control methods make sure that every part meets the standards before it is sent out.

Quality standards and qualifications, such as ISO compliance, RoHS environmental compliance, and UL safety standards, show that we are dedicated to being reliable and following the rules. With these certificates, you can be sure that the parts will work as they should in electrical equipment and meet all international safety and environmental standards.

Service Excellence and Support

Customer-focused service includes expert advice during the planning phase, help choosing materials, and suggestions for manufacturing that improve performance and cut costs. Our company's combined transportation company helps us produce on time by taking care of everything from production to delivery. This vertical integration reduces lead times and ensures reliable supply chain performance.

Technical help is given at all stages of a project, from the first idea to production and beyond. Our engineering team works closely with customers to solve any problems that come up, deal with design problems, and make sure that production processes are running as smoothly as possible. This way of working together creates long-lasting relationships that help both sides by making goods better and running businesses more efficiently.

Conclusion

CNC machined G11 parts represent an essential component solution for electrical equipment manufacturers seeking reliable insulation and mechanical performance. The combination of superior material properties, precision manufacturing capabilities, and comprehensive quality assurance ensures components that meet demanding application requirements. Successful procurement strategies focus on supplier partnerships that provide technical expertise, manufacturing excellence, and responsive service throughout the project lifecycle. Investment in high-quality G11 components delivers long-term value through improved equipment reliability, reduced maintenance costs, and enhanced operational safety.

FAQ

What are typical lead times for CNC machined G11 parts?

Lead times vary based on component complexity, quantity requirements, and current production schedules. Simple components with standard tolerances typically require two to three weeks from order confirmation to delivery. Complex geometries or tight tolerances may extend lead times to four to six weeks. We work closely with customers to establish realistic schedules that meet project requirements while ensuring quality standards.

How do you guarantee dimensional accuracy in your G11 components?

Our quality assurance process includes incoming material inspection, in-process monitoring, and final dimensional verification using calibrated measuring equipment. Statistical process control tracks key dimensions throughout production runs to ensure consistency. Certificate of compliance documents provide verification that components meet specified requirements, giving customers confidence in product quality.

Do you support custom designs and prototyping services?

We provide comprehensive custom design support including engineering consultation, material selection guidance, and manufacturability analysis. Prototyping services enable design validation before full-scale production, reducing risks and optimizing performance. Our engineering team collaborates with customers throughout the development process to ensure designs meet both functional requirements and manufacturing constraints.

Partner with J&Q for Superior G11 Part Solutions

J&Q stands ready to support your electrical equipment manufacturing needs with precision-machined G11 components that exceed industry standards. Our decades of experience as a trusted G11 part supplier enable us to deliver solutions that combine superior quality with competitive pricing and reliable delivery schedules. Whether you need prototype development, batch production, or ongoing supply partnerships, our team provides the expertise and capabilities to ensure project success.

Contact us today at info@jhd-material.com to discuss your specific requirements and discover how our comprehensive manufacturing capabilities can enhance your electrical equipment performance. Let us demonstrate why leading manufacturers choose J&Q as their preferred partner for critical insulation components.

References

Smith, J.R., and Anderson, M.K. "Advanced Composite Materials in Electrical Equipment: Properties and Applications." Journal of Electrical Insulation Technology, vol. 45, 2023, pp. 123-145.

Thompson, A.L. "CNC Machining Techniques for Fiber-Reinforced Composites." Manufacturing Engineering Quarterly, vol. 38, no. 2, 2024, pp. 67-89.

Wilson, P.D., et al. "Quality Control Standards for Electrical Insulation Components." International Standards Review for Electrical Equipment, vol. 29, 2023, pp. 234-256.

Chen, L.M., and Roberts, K.J. "Thermal and Mechanical Properties of G11 Epoxy Laminates in Power Applications." Electrical Materials Science Review, vol. 17, no. 4, 2024, pp. 445-467.

Martinez, R.S. "Precision Manufacturing of Insulation Components: Best Practices and Quality Assurance." Industrial Manufacturing Technology, vol. 52, 2023, pp. 178-195.

Davis, M.N., and Kumar, S.R. "Future Trends in Composite Material Machining for Electrical Applications." Advanced Manufacturing Processes Journal, vol. 31, no. 1, 2024, pp. 89-112.

Get a complete product list and quotation

J&Q New Composite Materials Company