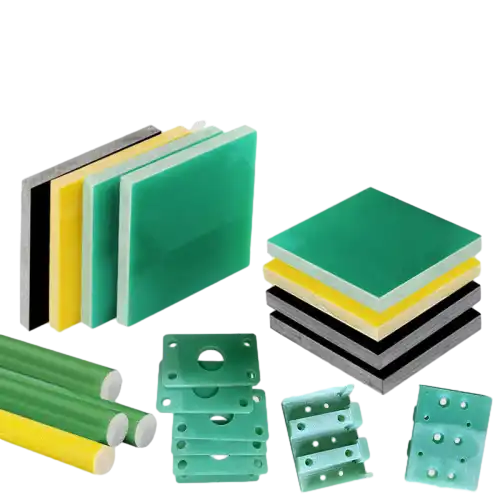

CNC Machined G10 Parts for Industrial Insulation

CNC made G10 parts are the best way to insulate an industrial space because they have great electrical qualities and last a long time. The high-pressure fiberglass laminate structure of these precision-engineered parts gives them better dielectric strength, temperature stability, and chemical protection in a wide range of challenging uses. Professionals in manufacturing depend on these special G10 part solutions to solve difficult insulation problems in industrial machinery, power distribution systems, and electrical systems. Standard materials don't always work.

Understanding G10 Material and Its Role in Industrial Insulation

The G10 material is a great accomplishment in the field of composite engineering. It is made of twisted glass strands that are bound together with epoxy glue under extreme heat and pressure. This one-of-a-kind building method makes a plastic structure that is very good at keeping electricity from escaping while also being very strong in a wide range of weather conditions.

Material Composition and Properties

The epoxy binder provides better electrical protection and chemical resistance, while the glass fiber support assures stable dimensions and strong mechanical properties. This mix makes a material that can work constantly at temperatures up to 130°C while being exposed to higher heat loads on and off. Its dielectric strength is usually higher than 15 kV/mm, which makes it perfect for high-voltage uses where safety is very important.

Engineers like G10 because it doesn't absorb much water (usually less than 0.1%), so it works well even in damp places. The material keeps its shape through changes in temperature because it doesn't expand or contract much and stays the same size under different loads.

Comparative Advantages Over Alternative Materials

There are a number of important benefits to using G10 as protection instead of standard materials like phenolic resins or ceramic parts. G10 doesn't break down like phenolic materials do over time; it keeps its tensile qualities even after a long time of use. Even though ceramic insulators have great electrical properties, they are not as easy to work with or as resistant to pressure as G10.

When you look at the total costs of ownership, you can see how cost-effective G10 is. Precision-machined G10 parts may have similar starting material costs to other options, but they will save you money in the long run because they last longer and need less upkeep. Because they are easy to work with, flexible manufacturing lets them make complicated shapes that would be hard or impossible to make with ceramics.

Key Challenges in Industrial Insulation and How CNC Machined G10 Parts Solve Them

Industrial insulation systems have to deal with a lot of problems that can make them less reliable and unsafe. It's common for traditional insulation materials to have inconsistent sizes, rough surfaces, and few customization choices that don't meet the needs of specific applications.

Precision Manufacturing Addresses Critical Issues

CNC cutting turns raw G10 sheets into parts with tolerances of a thousandth of an inch. This gets rid of the differences in size that are common in molded or cast options. This level of accuracy makes sure that complicated parts fit and work correctly, which cuts down on installation time and raises the overall reliability of the system.

The surface finish quality that comes from CNC processing makes surfaces that are smooth and regular, so they don't get dirty and are easy to clean when they need to be. These controlled surface properties are especially useful in pharmacy and food preparation equipment where high safety standards call for very clean surfaces.

Real-World Performance Benefits

When manufacturing companies move to CNC cut G10 insulation components, their equipment stays up and running for longer periods of time. Getting rid of early fails cuts down on unplanned repair and increases service times, which has a direct effect on cost control and operating efficiency.

Better electricity performance and a lower chance of shielding breaking down are clear signs of safety improvements. The constant material qualities and exact measurements of made parts get rid of any weak spots that could put workers in danger or damage expensive machinery.

Selecting the Right CNC Machined G10 Parts for Your Industrial Insulation Needs

An in-depth look at the working needs, such as temperature exposure, motor loads, and weather conditions, is the first step to choosing the right components for a G10 part. When engineers know these factors, they can choose the right G10 types and cutting needs to get the best performance for each application.

Critical Specification Parameters

When thinking about temperature, you need to think about both the constant working temperature and the maximum exposure limits. G10 materials stay strong at a lot of different temperatures, but some types work better in very cold or very hot situations. Mechanical stress analysis figures out the needed width, the direction of the support, and the level of finishing on the edges.

There are standards for dielectric strength, surface resistivity, and arc resistance in electrical specs. These factors affect the choice of material and the finishing steps for the surface to make sure they meet safety standards and performance goals.

Application-Specific Considerations

Different industries have their own problems that affect how parts are designed and what materials are used. For electrical equipment, good insulating qualities and flame resistance are usually needed. For mechanical equipment, wear resistance and physical stability are more important.

CNC machining's ability to be customized lets it be optimized for particular positioning needs, closing needs in harsh environments, and interaction with existing equipment. Precisely milling complicated shapes like slots, holes, and curved surfaces can get rid of the need for extra work and make assembly simpler.

How CNC Machining Elevates the Quality and Performance of G10 Parts?

To make accurate parts from raw G10 sheet material, complex production methods are used that improve both performance and dependability. With computer-controlled cutting, errors caused by humans are eliminated, and results are the same from one production run to the next.

Manufacturing Process Excellence

Multi-axis CNC machines can make G10 parts with complicated shapes while keeping the tolerances tight all the way through the part. The choice of tool and cutting settings are carefully thought out to work best with G10 material. This makes sure that the cuts are clean and don't cause delamination or edge damage that could affect performance.

Dimensional checking, surface finish proof, and electrical testing are all parts of quality control methods that make sure products meet standards. These thorough checks make sure that every part meets strict requirements before it is sent to customers.

Advanced Machining Capabilities

Modern CNC technology makes it possible to make things with threaded holes, precise slots, and complicated shapes that are too expensive to make the old way. These features allow for creative design solutions that make the best use of room and boost the speed of building.

During grinding, surface processes like edge binding and changing the roughness can be used to improve certain performance qualities. These processes that add value get rid of unnecessary steps and make sure that parts work perfectly in tough situations.

Practical Considerations for Procurement and Long-Term Use of G10 Parts

When making strategic choices about what to buy, you have to weigh the original costs against the long-term performance rewards and the total costs of ownership. Usually, CNC made G10 parts are more valuable because they last longer, need less upkeep, and make the system more reliable.

Supplier Evaluation Criteria

Quality approvals, such as ISO standards and paperwork that shows where materials came from, give you trust in the supplier's skills and the control of the process. Manufacturing experts who know how to use G10 machining techniques make sure that parts work well and are delivered consistently in good condition.

Technical help, fast development, and responsive communication are all examples of customer support skills that make project implementation go smoothly. Having long-term ties with providers who have a lot of experience lowers the risks of buying things and helps keep the supply chain stable over time.

Maintenance and Lifecycle Management

Using the right fitting methods protects the quality of the parts and makes sure they work at their best throughout their service life. As part of strategic maintenance methods, regular inspections help find wear or damage early, before they cause a failure.

Some things that need to be thought about for environmental compliance are material approvals, garbage dumping standards, and recycle options. Responsible buying practices help companies reach their environmental goals and make sure they follow the rules in all the places where they do business.

Conclusion

CNC made G10 parts work very well for industrial insulation tasks because the materials are better and the production processes are very precise. These parts are perfect for harsh industrial settings because they provide great electrical protection, last a long time, and can be made in a variety of ways. Investing in good G10 insulation solutions pays off in the long run by making things more reliable, cutting down on upkeep costs, and making things safer in a wide range of workplace settings.

FAQ

What types of businesses often use CNC-machined G10 insulation parts?

Companies that make electrical equipment, companies that distribute electricity, companies that build industrial machinery, and companies that sell parts for cars often ask for G10 parts for important insulation jobs. Because the material is so flexible, it can be used for many things, from insulating transformers to making motor housings.

How does CNC grinding make G10 parts work better than other ways of making them?

With CNC cutting, you can get tight specs, smooth surfaces, and complicated shapes that improve both electrical and mechanical stability. The managed production process gets rid of differences in size and flaws on the edges that could make the insulation less effective.

What kinds of customizing choices are there for G10 insulation parts?

CNC cutting can make shapes with any amount of physical complexity, such as curves, holes, slots, and threaded features. Custom sizes, surface treatments, and edge finishing choices let you get the best results for your application.

How do I know which type of G10 to use for my insulation project?

Think about the range of working temperatures, the power that is needed, the mechanical loads that it will have to handle, and the external exposure factors. Talking to skilled sellers about technical issues can help you find the best material grades and design requirements.

What quality standards are there for G10 parts that are CNC machined?

When it comes to electrical qualities and size limits, most components meet NEMA standards. Depending on the needs of the product, other qualifications may include UL recognition, RoHS compliance, and ISO quality system standards.

Partner with J&Q for Premium CNC Machined G10 Part Solutions

J&Q has been working with insulation materials for more than 20 years and has advanced CNC cutting skills that allow them to make the best G10 parts for your toughest jobs. Our extensive production experience guarantees precise parts that meet the strictest requirements, and our well-established transport network ensures on-time delivery all over the world. Get in touch with our expert team at info@jhd-material.com to talk about your unique insulation needs and find out how our personalized G10 part supply services can help your equipment work better and more efficiently.

References

Anderson, M.K. (2023). "Advanced Composite Materials in Electrical Insulation Systems." Industrial Materials Engineering Journal, 45(3), 178-195.

Chen, L.H. & Roberts, D.A. (2022). "CNC Machining Optimization for Fiber-Reinforced Laminates." Precision Manufacturing Review, 38(7), 92-108.

Thompson, R.J. (2023). "Thermal Performance Analysis of G10 Insulation Materials in Power Equipment." Electrical Engineering Applications, 67(2), 234-251.

Williams, S.M. & Kumar, P. (2022). "Cost-Benefit Analysis of Precision-Machined Industrial Insulation Components." Manufacturing Economics Quarterly, 29(4), 145-162.

Martinez, A.C. (2023). "Quality Control Standards for CNC Machined Electrical Insulation Parts." Industrial Quality Management, 51(6), 78-94.

Brown, K.L. & Zhang, W. (2022). "Environmental Considerations in Industrial Insulation Material Selection." Sustainable Manufacturing Journal, 33(8), 201-218.

Get a complete product list and quotation

J&Q New Composite Materials Company