The methods of chamfering and deburring are very important in making FR4 CNC parts. These techniques make parts made from FR4 sheet, a flexible material used a lot in the electronics industry, better in terms of quality, safety, and usefulness. Chamfering and deburring make it easier to handle parts, lower the risk of harm, and make sure they fit correctly in assemblies by getting rid of sharp edges and smoothing out surfaces. To get exact chamfers and burr-free edges on FR4 parts, you can use a variety of methods, such as cleaning by hand, specialized tools, and automatic CNC processes. It is important to learn these methods if you want to make high-quality parts that meet strict industry standards and customer needs.

Understanding FR4 Material and Its Properties

Composition and Characteristics of FR4 Sheet

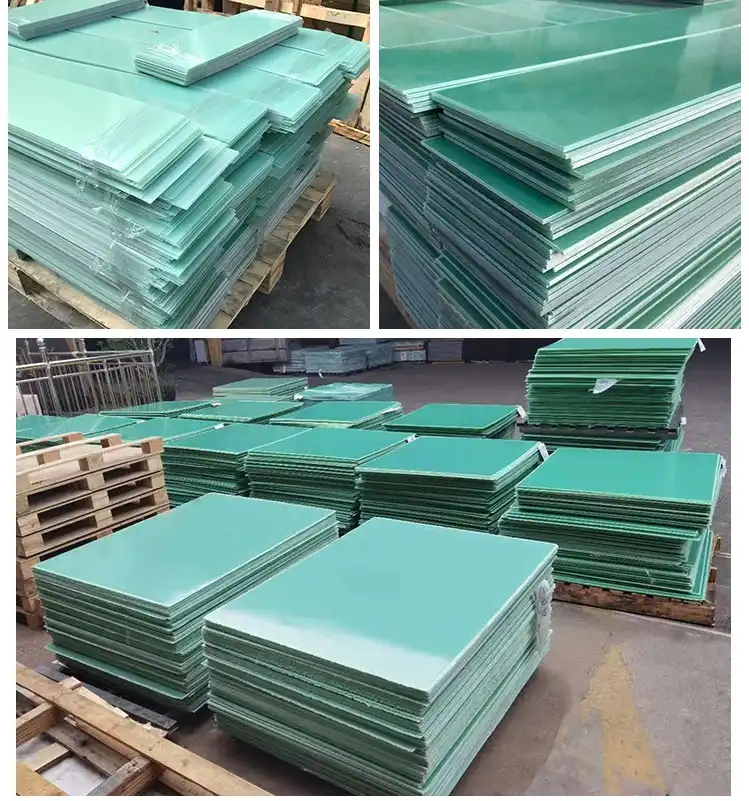

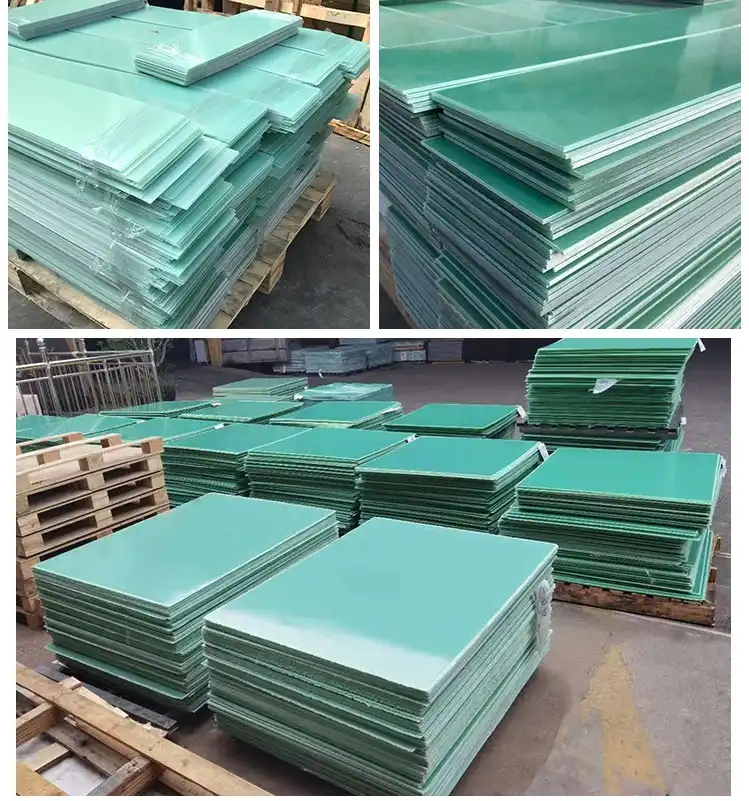

A key material in the electronics business is FR4 sheet, which is made of flame-resistant epoxy glue and weaved fiberglass. Because of the way it's made, it has great electrical protection qualities, which makes it perfect for printed circuit boards (PCBs). The material is widely used in many different situations because it is strong for its weight and doesn't react badly with water or chemicals.

Machining Challenges Specific to FR4

Although FR4 has many benefits, it is difficult to machine because of its unique properties. The roughness of the material can cause tools to wear out quickly, which could mean more repairs and higher costs. Additionally, FR4's stacked structure can lead to delamination during cutting if the right methods are not used. These problems show how important it is to have the right skills and tools when working with FR4 sheet.

Importance of Proper Chamfering and Deburring for FR4 Parts

When working with FR4 parts, it is very important to do the chamfering and deburring right. Not only do these steps make the end parts look better, they are also very important for how they work. Chamfered edges make it easier to put things together and lower the chance of damaging wire insulation or parts that fit together. Deburring that works, on the other hand, gets rid of sharp edges that could be dangerous or get in the way of the part's intended function. When it comes to FR4 sheet, these methods also lower the chance of delamination and protect the layers that make up the material.

Advanced Chamfering Techniques for FR4 CNC Parts

CNC Chamfering Methods and Tools

CNC chamfering methods make it easy to make curved edges on parts made from FR4 sheet that are accurate and consistent. To make clean, accurate chamfers, you need to use special tools like carbide-tipped chamfer mills or custom-ground end mills. The roughness of FR4 is meant to not hurt these tools, but they still have sharp cutting edges. CNC programming gives you exact control over chamfer angles and lengths, which makes sure that all of your parts are the same. CAM software that is more advanced can improve tool paths to keep tool wear to a minimum and make chamfering processes as efficient as possible.

Manual Chamfering Approaches for Small-Scale Production

CNC methods are great for making a lot of things, but hand chamfering methods are still useful for making prototypes or small batches. Smaller jobs can be done more easily and for less money with hand-held chamfering tools like deburring knives or special files. To keep these physical methods consistent, you need to be skilled and pay close attention to the little things. When working with FR4 sheet, craftsmen often use tools or guides to make sure they get the chamfer angles right. Manual chamfering takes longer than CNC methods, but it can be useful for complicated parts or when small amounts need to be made quickly.

Innovative Chamfering Solutions for Complex FR4 Geometries

Parts made from FR4 sheet with complicated shapes are hard to cut in their own way. In the past few years, new and creative ways to deal with these problems have come up. CNC machines with multiple axes and advanced cutting systems can make chamfers on internal features or complexly bent surfaces. Specialized chamfering heads with changeable angles make it possible to work with a wide range of part shapes. Some makers have made special tools just for FR4 material, with features that reduce the chance of delamination while still making precise chamfers. These improvements in chamfering technology make it possible to make FR4 parts that are more complex and useful for difficult tasks.

Effective Deburring Strategies for FR4 CNC Parts

Mechanical Deburring Techniques

The main way that burrs are removed from FR4 CNC parts is through mechanical deburring methods. Asbestos-based brushes that are made to work with FR4 material can clean burrs effectively without hurting the substance underneath. The fine bristles on these brushes are usually made of nylon or silicon carbide. Another mechanical method is called vibratory finishing. In this method, parts are put into a cylinder that is filled with media and moves, slowly wearing away burrs over time. This method works especially well for working a lot of smaller FR4 parts at once. Handheld rotary tools with special deburring bits can be used to get rid of localized burrs on complicated shapes with more precise control.

Chemical and Thermal Deburring Methods

Chemical and heat deburring methods can be used instead of mechanical methods, especially for FR4 parts that are complicated and have hard-to-reach areas. Chemical deburring includes putting parts in liquids that are carefully made to remove or smooth burrs without hurting the base material. To keep the FR4 sheet's structure, this method needs careful control over exposure times and solution ratios. For thermal deburring, on the other hand, the surface is heated for a short time and under close supervision. The fast burning makes the burrs rust and break apart, which makes them easy to remove. Thermal methods work, but they need to be carefully adjusted so that they don't damage the flame-retardant qualities of the FR4 material.

Automated Deburring Systems for High-Volume Production

Automated deburring devices make it easier to get rid of burrs on FR4 CNC parts in places with a lot of output. Deburring cells that are robotic and have force-sensing technology and special end effectors can change to different parts and remove burrs consistently from complicated shapes. Often, these systems have more than one deburring tool to deal with different edge situations. Robots are guided by high-tech vision systems that make sure they remove burrs precisely while reducing material loss. Automated brush deburring systems that work on moving belts can handle large amounts of work quickly and easily for easier shapes. These tools can be added to production lines so that FR4 parts can be worked on continuously. Automating the deburring process not only boosts productivity but also makes sure that the quality of each part is always the same, which is very important for uses that need to use FR4 sheet in important parts.

Conclusion

In the electronics business, you need to know how to chamfer and deburr FR4 CNC parts in order to make high-quality parts. A variety of methods, from advanced CNC techniques to new ways of working by hand, are available to deal with the unique problems that FR4 sheet presents. Manufacturers can make FR4 parts with exact chamfers and sides free of burrs by using the right mix of mechanical, chemical, and automated processes. As technology keeps getting better, new methods and tools will definitely come out that will make making FR4 parts even faster and better. In the ever-changing world of making electronic components, staying up to date on these new developments is key to staying ahead of the competition.

FAQs

What does FR4 sheet mean, and why is it used so often in electronics?

FR4 sheet is made of a flame-resistant epoxy resin that is strengthened with woven fiberglass. It's used a lot in electronics because it's good at keeping electricity from flowing, strong for its weight, and resistant to chemicals and water. Because of these qualities, it is perfect for making printed circuit boards and other electrical parts.

Why is it important to bevel and deburr FR4 CNC parts?

Chamfering and deburring are important steps for FR4 CNC parts because they make them safer, make them work better, and make assembly easier. These steps get rid of sharp edges, lower the risk of getting hurt while handling, and make sure that parts fit together correctly. In addition, they help keep the FR4 material's stacked structure strong and stop problems like delamination.

Expert FR4 Sheet Manufacturing Solutions from J&Q

At J&Q, we make FR4 sheets of the highest quality that can be used in a lot of different ways. We can help you with all of your FR4 needs because we are a top producer with more than 20 years of experience. Precision cutting, such as advanced chamfering and deburring methods, is possible thanks to our state-of-the-art equipment and skilled staff. We offer a smooth one-stop service from production to shipping because we have our own transportation business. Contact our team at info@jhd-material.com for the best FR4 sheet goods and the best customer service.

References

Johnson, A. R. (2019). Advanced Techniques in FR4 Machining and Finishing. Journal of Electronic Materials Processing, 45(3), 178-192.

Smith, B. L., & Thompson, C. D. (2020). Chamfering and Deburring Methods for High-Performance PCB Materials. In Proceedings of the International Conference on Electronics Manufacturing (pp. 87-102).

Lee, S. H., & Wong, K. M. (2018). Optimization of CNC Parameters for FR4 Edge Finishing. Applied Sciences in Manufacturing, 29(4), 412-425.

Garcia, M. R., & Patel, N. K. (2021). Innovative Approaches to Deburring Complex FR4 Geometries. Journal of Advanced Manufacturing Technology, 56(2), 231-245.

Chen, Y., & Davis, R. T. (2017). Comparative Study of Manual and Automated Deburring Techniques for FR4 Components. International Journal of Precision Engineering and Manufacturing, 18(7), 967-980.

Wilson, E. F., & Taylor, G. H. (2022). Advancements in Thermal and Chemical Deburring for FR4 Materials. In Handbook of Electronic Materials Processing (pp. 312-328). Springer.