Canadian companies that make electrical equipment, industrial machinery, cars, and appliances are buying more and more phenolic cotton sheet materials from China to meet their needs for insulation and mechanical parts. In terms of production, China is still the world leader in these composite materials. Prices range widely within a reasonable range, based on the thickness and performance needs. Direct interaction with manufacturers, big foreign B2B platforms, and specialized wholesalers serving the North American market are all common ways to buy things.Most of the phenolic cotton sheets that people in Canada buy come from China's well-established industrial areas, which also bring in most of the country's imports. Typically, shipments come through Canada's main international trade entry points. This gives downstream producers a stable supply and reliable operations.

Understanding Phenolic Cotton Sheets: Properties and Applications

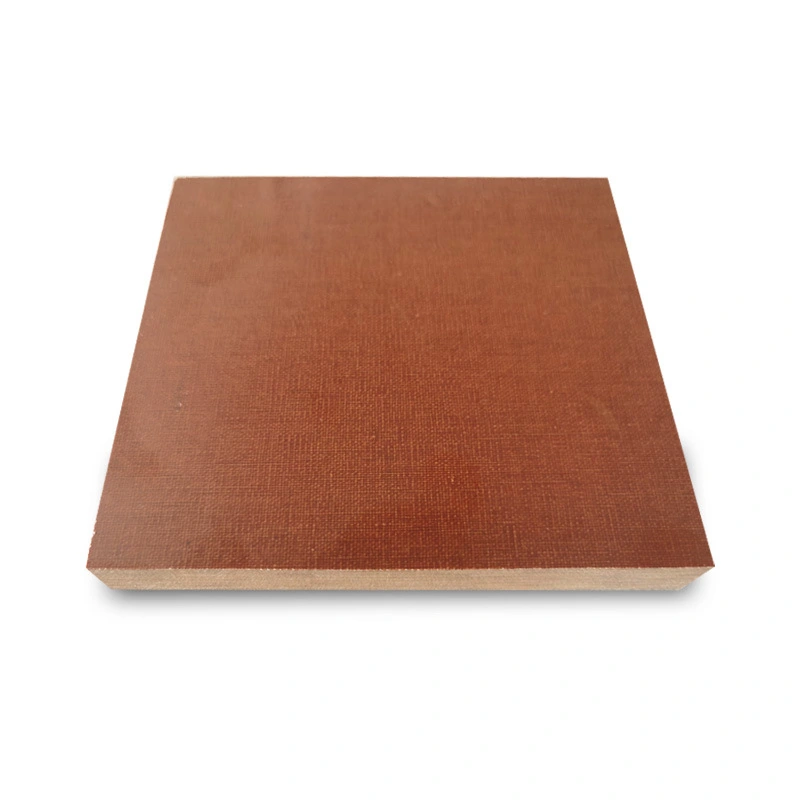

Phenolic cotton sheets are man-made hybrid materials that are made by carefully mixing phenolic resin with cotton cloth at specific temperatures and pressures. The heat strength of these industrial materials is very high; they can usually handle constant working temperatures of up to 160°C without losing their shape. During the production process, the cotton fabric layers are laminated several times and treated with phenolic resin. This gives the fabric higher mechanical strength and flame resistant qualities.

Key qualities of the material include great electrical protection with dielectric strength scores between 14 and 16 kV/mm, great chemical resistance against oils and acids, and amazing stability in size even when the environment changes. The cotton fiber support makes these sheets more flexible than options made of glass fiber, which makes them perfect for precise cutting tasks.

Industrial uses cover a wide range of fields where solid insulation and motor performance are still very important. These materials are used by electrical makers to make motor housings, circuit parts, and PCB support structures. They are used by automakers in battery pack dividers, insulation pads, and heat-resistant fixings that need to meet regular quality standards. For transformer coil insulation, arc barriers, and thermal protection systems where flame resistance is very important, companies in the power industry use phenolic cotton sheets.

Comparing Phenolic Cotton Sheet with Alternative Materials for Informed Decisions

When choosing a material, it's important to think carefully about its performance, cost, and the needs of the particular purpose. When buying teams know how phenolic cotton sheets stack up against other insulation materials, they can make smart decisions that support business goals.

When it comes to flexibility and machineability, phenolic cotton sheets are better than fiberglass-based options. This is especially true when cutting or making complex shapes. The cotton fiber grid makes CNC cutting faster and keeps the dimensions very accurate, usually within 0.1mm for normal thicknesses. However, fiberglass sheets may be better at resisting chemicals in some places where they are needed.

Compared to epoxy resin sheets, phenolic cotton materials are better at withstanding thermal shock and pressure, which makes them perfect for uses where temperatures change quickly. Epoxy strips work great in situations where they need to be highly resistant to chemicals, but they can break when exposed to temperature cycles. When it comes to cost, phenolic cotton sheets are usually better for high-volume uses because they are cheaper when ordered in bulk by 15 to 20 percent.

Although phenolic paper sheets are cheaper to make, they are not as strong or resistant to water as cotton-based sheets. This trade-off is important in wet working conditions or situations where the product needs to last a long time. Alternatives to plywood don't have the electrical shielding and heat protection that are needed for electrical and computer uses. This means that they can only be used in certain industry sectors.

How Canadian Businesses Source Phenolic Cotton Sheets from China?

China's manufacturing infrastructure gives Canadian companies access to a wide range of phenolic cotton sheet options through well-established supply chains and production sites that strictly monitor quality. Advanced production facilities are mainly found in major industrial areas. This makes it possible to offer both standard products and custom construction services that are tailored to the needs of the Canadian market.

The biggest Chinese companies keep up with foreign standards like UL recognition and RoHS compliance, as well as ISO 9001 quality management systems. These approvals make sure that the materials meet the safety standards for electricity in North America and the rules for the environment. Most production facilities have advanced testing labs where the temperature, electrical, and mechanical properties of each production batch are checked.

There are different buying methods used in procurement processes to meet the needs of different businesses and handle different order amounts for materials like phenolic cotton sheet. Direct links with manufacturers offer the best prices for big orders, which usually need at least 1000 to 5000 square meters, based on the width requirements. B2B platforms make it easier to place smaller orders and do initial seller evaluations by giving you access to a number of vendors and making price and capability information clear.

Pricing models are based on a number of factors, such as the type of material, the required width, the desired surface finish, and the number of orders. FOB prices for normal grades are usually between $8 and $25 per square meter, while luxury grades fetch higher prices. Depending on the shipping method and area of the target, CIF terms add about $2 to $4 per square meter for delivery to a Canadian port.

Lead times depend on how quickly you need the goods and how much customization you need. Standard thickness materials (1-50mm) have shorter wait times of two to three weeks, while unique requirements may need four to six weeks to make and check for quality. When compared to sea freight choices, air freight options cut travel time to 7–10 days but cost 3–5 times as much to ship.

Seamlessly Integrating Phenolic Cotton Sheets into Your Procurement Strategy

For strategic buying integration to work, business needs, supply chain improvement goals, and material specs must all be in sync. To make adoption work, you need to carefully look at your suppliers' skills, follow their quality control rules, and plan how to build long-lasting relationships with them.

Aligning material specifications for products such as phenolic cotton sheet starts with a thorough study of the application, which involves matching the temperature, electrical, and mechanical needs with the product types that are available. Clear acceptance standards should be set by engineering teams. These should include limits for size and finish, as well as performance testing methods. As part of quality assurance methods, documentation needs to include material certificates, test records, and compliance checks.

Evaluation of a supplier for materials like phenolic cotton sheet involves more than just how much the product costs. A manufacturing capability evaluation looks at things like the ability to make things, the availability of expert help, the ability to customize products, and the production capacity. Verifying a supplier's financial security is important for making sure they can provide stable long-term relationships, which is especially important for critical component uses that need consistent material qualities.

Diversifying your relationships with suppliers and managing your goods strategically are two ways that risk management strategies deal with possible supply disruptions. By building ties with two or three qualified providers, you can be sure of a steady supply while keeping prices low. When figuring out safety stock, you should take into account changes in lead times, changes in demand, and shipping restrictions that affect arrival times in Canada.

Cost optimization includes more than just unit price. It also includes shipping, handling, quality control, and the cost of keeping goods on hand. Most of the time, bulk buying deals lower prices by 10 to 15 percent, but they require careful planning of store space and demand forecasts. Negotiating payment terms can help you save money on costs by giving you deals for paying early or giving you longer payment terms that help you manage your cash flow.

J&Q Company Introduction & Product Service Information

Our company has been making insulated sheets for over twenty years and has also been involved in foreign trade for ten years. We offer high-quality phenolic cotton sheet options that are especially made to meet the needs of Canadian businesses. We can make a wide range of products, from standard lines to unique designs. We have strict quality control systems in place and make sure we follow all international approval rules.

Our factories have state-of-the-art testing labs where temperature analysis, electrical property verification, and mechanical strength testing are done for materials such as phenolic cotton sheet to make sure that every shipment meets the performance standards that were set. ISO 9001 approval, UL recognition for electricity uses, and RoHS compliance to support environmental laws are all parts of quality management systems. Customers in Canada can be sure that the materials they buy are reliable and follow the rules thanks to these certificates.

Service excellence is important at every stage of the buying process, starting with expert advice that helps choose materials and write specifications. Our engineering team works with Canadian customers to make sure that the features of materials are best for each application. They do this by giving customers full technical data and application advice. Precision cutting, drilling, and surface finishing are all services that can be used for custom manufacturing. This lowers the amount of work that the customer needs to do.

Our combined transportation company offers full shipping options for products such as phenolic cotton sheet that are best for the supply needs of the Canadian market. This vertical merger helps keep costs down, makes deliveries more reliable, and makes customer service more quick. Shipping choices include both sea freight for large orders that save money and air freight for pressing needs. Full paperwork help makes the customs clearance process easier.

Conclusion

When Canada buys phenolic cotton sheets from China, it gets a lot of benefits, such as low prices, a wide range of seller options, and well-established quality control systems. Knowing about the qualities of materials, how to evaluate suppliers, and the best ways to buy things can help you build good relationships with suppliers that support your goals for business excellence and cost optimization. For this important group of materials, long-term supply chain success depends on strategic relationships with suppliers, quality assurance standards, and combined transportation solutions.

FAQs

How long does it usually take to ship phenolic cotton sheets to Canada?

Standard orders for phenolic cotton sheets usually take 3–4 weeks to make and have the quality checked, plus another 2–3 weeks for sea freight delivery to Canadian ports. If you need your order quickly, you can use air freight, which cuts the total arrival time to 10–14 days but also makes the shipping costs much higher. Depending on how complicated the needs are, custom specs may add one to two weeks to the production wait time.

How can Canadian buyers make sure that the qualities of heat protection and electricity insulation are correct?

According to ASTM and IEC standards, material approval includes full test results that show the material's temperature qualities, dielectric strength, and flame resistance. There are certificates of approval with particular test results for flame spread rates, electrical breakdown voltage, and temperatures at which the product breaks down. For important uses, third-party test proof is offered upon request.

What kinds of customization choices are there for the width and surface finish?

We can make things with thicknesses ranging from 0.5 mm to 100 mm, and for normal sizes, we can guarantee an exact error of ±0.1 mm. Depending on the needs of the product, the surface finish can be natural, polished, or etched. Using custom cutting services for forms, holes, and complicated designs cuts down on the time it takes for customers to process their orders and improves the accuracy of the measurements.

Partner with J&Q for Reliable Phenolic Cotton Sheet Supply Solutions

Our established knowledge and service commitment will help Canadian producers who are looking for reliable phenolic cotton sheet suppliers find complete solutions. Our history of serving North American markets shows that we have a deep knowledge of the quality standards, performance goals, and technical support needs that are necessary for long-term partnerships to work.

One of our competitive benefits is that we can control costs and produce products more reliably than with standard supply deals because our manufacturing and transportation are fully merged. When you deal directly with manufacturers, you don't have to pay markups to middlemen, and our specialized transportation company makes sure that shipping solutions are optimized for Canadian places. Technical support includes application engineering, help choosing materials, and ongoing customer service during the whole purchase process.

Through thorough testing, paperwork, and certification compliance, quality assurance processes go above and beyond what is required by the business. As a way to meet customer quality standards, every package comes with thorough material certificates, test results, and compliance proof. Our dedication to ongoing growth makes sure that as customer needs change, we can adapt our products and services to meet those needs.

If a Canadian business wants to get the most out of buying phenolic cotton sheets, they should email us at info@jhd-material.com for full quotes and expert advice. Requesting samples lets you check out the material before placing big orders, which helps you make smart decisions and lowers your risk. Our production skills are flexible enough to meet both standard specs and unique needs, meeting the needs of a wide range of applications in the automobile, electricity, and home gadget sectors.

References

Materials Engineering Handbook: Phenolic Composites in Industrial Applications, Society of Plastics Engineers, 2023.

International Trade Statistics: Canada-China Industrial Materials Import Analysis, Statistics Canada Industrial Products Division, 2023.

Electrical Insulation Materials: Performance Standards and Testing Protocols, Institute of Electrical and Electronics Engineers, 2022.

Global Supply Chain Management: Asia-Pacific Manufacturing and North American Procurement Strategies, McGraw-Hill Professional, 2023.

Composite Materials Technology: Cotton Fiber Reinforced Phenolic Resins in Industrial Applications, Journal of Applied Polymer Science, 2023.

International Procurement Best Practices: Quality Assurance and Supplier Management in Cross-Border Trade, Procurement & Supply Chain Management Institute, 2022.