China's NEMA CE sheets are very popular in the Middle East because they are of high quality, don't cost too much, and have a stable supply chain infrastructure. A lot of Chinese companies have become leaders in their fields by making electrical insulation materials that meet strict international standards and are priced competitively. The NEMA CE sheet rating has better chemical protection and electrical insulation qualities that are needed in tough industrial settings in the Middle East. Chinese sellers can consistently meet the high standards of electrical builders, industrial engineers, and sourcing experts across the region because they have advanced manufacturing techniques and can save money by buying in bulk.

Understanding NEMA CE Sheets: Properties, Specifications, and Applications

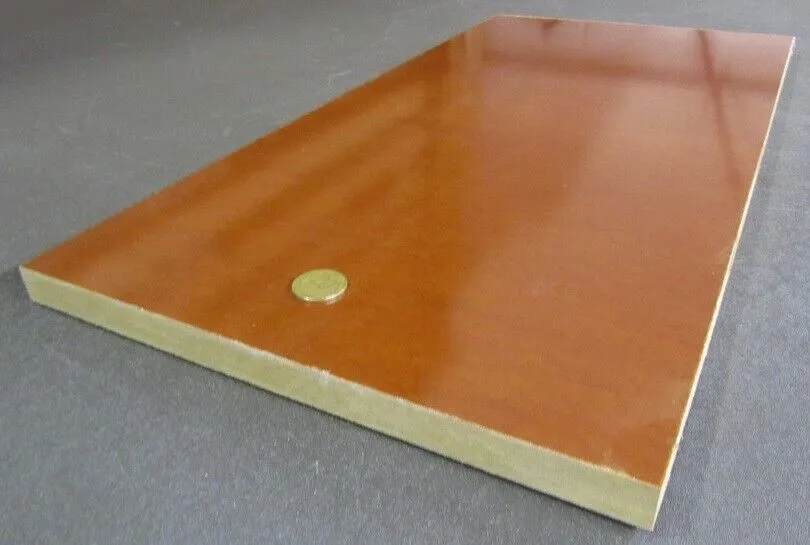

When it comes to electrical insulation laminates, NEMA CE sheets are a special kind that are made for uses that need extra chemical protection and dielectric strength. The National Electrical Manufacturers Association has approved these materials, which means they will always work well in harsh industrial settings.

As one of their main features, CE grade laminates are very resistant to acids, alkalis, and different chemical agents. Temperature stability ranges usually cover -40°C to 155°C, which means they can handle the harsh weather that is popular in Middle Eastern factories. The dielectric strength is usually higher than 16 kV/mm, making it a good choice for high-voltage uses that need solid electrical protection.

In the Middle East, these soundproofing products are used for a wide range of tasks. They are used by companies that make electrical tools in switchboard systems, transformer housings, and motor parts. Chemical processing plants use their ability to prevent rust to keep equipment from touching other equipment and to support structures. These sheets are used in the construction industry to make electricity panels and industrial building systems.

Why Chinese NEMA CE Sheets Meet Middle Eastern Market Needs?

By strategically investing in new industrial methods and quality control systems, Chinese companies have changed the way electrical shielding materials are made. This new technology makes it possible to consistently make NEMA grade laminates that work better than foreign standards.

The edge over competitors comes from a few main things that help Middle Eastern buying teams:

Chinese sellers can now offer prices for materials like NEMA CE sheet that are 20–30% lower than those in Europe or North America because they are more efficient at making their products. Leading makers keep their ISO 9001 approval and use strict testing methods throughout their production processes, so this cost benefit doesn't hurt quality.

- Advanced Manufacturing Infrastructure: Modern factories use automatic sealing systems and precise cutting tools to make sure that the dimensions are accurate to within ±0.05mm. Quality control systems keep an eye on every step of the production process, from mixing the glue to doing the final check. This makes sure that the qualities of the material are the same across large orders.

- Full Compliance with standards: Chinese makers work hard to get foreign standards like UL recognition, RoHS compliance, and REACH registration. These approvals give purchasing managers peace of mind that the materials they're buying meet the world standards for safety and the environment that are needed for foreign markets.

- The ability to customize: Custom thickness requirements, special surface treatments, and changed glue formulas can all be accommodated by flexible production methods. Engineering teams work directly with customers to create solutions that are tailored to each application and meet specific business needs.

Middle Eastern businesses can gain from these production skills in real ways, such as lower purchasing costs, faster wait times, and better technical help throughout the supply relationship.

Comparing NEMA CE Sheets from China with Other Materials and Origins

When you compare Chinese NEMA CE sheets to other products and supply sources, market research shows that they work better and are cheaper. When procurement workers understand these similarities, they can make better choices about where to source goods.

When compared to regular phenolic laminates, CE grade sheets are better at withstanding chemicals and keeping their temperature. This better performance means that the equipment will last longer and need less upkeep in the tough manufacturing settings that are popular in the Middle East.

When compared to European providers, Chinese makers offer the same level of technical performance while offering more open terms for buying and faster delivery times. European providers often have higher minimum orders and longer lead times, which can make project-based buying cycles harder to manage.

The performance traits listed below show why electrical insulation sheets made in China are better than those made in other countries:

- Material Consistency: Modern quality control methods make sure that there is more than a 3% difference between batches of the same material. This makes it possible to do accurate design calculations and lowers the chances of fitting problems in the field that can happen when material properties change.

- Chemical Resistance: Tests done in the lab show that it is very resistant to sulfuric acid, sodium hydroxide, and petroleum-based chemicals that are popular in industrial settings in the Middle East. Compared to normal phenolic options, this protection makes the service life 15 to 25 percent longer.

- Mechanical Strength Properties: The flexural strength is usually higher than 140 MPa, which makes the structure strong for mechanical support uses. Impact resistance values higher than 8 kJ/m² make sure that the product will last while it is being installed and used in harsh conditions.

Because of these performance benefits, as well as competitive prices and stable supply lines for products like NEMA CE sheet, Middle Eastern businesses are choosing Chinese-made electrical insulation products more and more for important tasks.

Procurement Guide: How to Buy NEMA CE Sheets from China for Middle East Markets

To buy electrical insulation materials from Chinese sellers successfully, you need to carefully check the suppliers' skills, quality standards, and shipping and delivery systems. Structured methods are used by experienced buying teams to find reliable supply partners and build long-term relationships with them.

The first step in evaluating a supplier is to check their manufacturing licenses and quality control systems. The best providers keep their ISO 9001 approval, use statistical process control, and give full test results for every batch of output. Testing of dynamic properties, checking of dielectric strength, and confirmation of chemical protection should all be part of the documentation.

When making an order, things to think about include the minimum amount needed, the customization choices, and when the goods will be delivered. Minimum orders are usually between 100 and 500 sheets, but this depends on the width and other requirements. Custom size choices can be used to meet the needs of a particular project without charging a lot more if the right amount of product is bought.

Coordinating logistics means choosing the right shipping methods and keeping track of customs paperwork. Sea freight is the most cost-effective way to move big orders, while air freight speeds up delivery for urgent needs. Suppliers with a lot of experience help with export paperwork and work with freight forwarders to make sure that customs clearance goes smoothly.

Protocols for quality assurance should include ways to check goods coming in and ways to audit suppliers. Setting clear acceptance standards and checking methods helps keep the supply chain reliable throughout the buying relationship and stops problems with quality.

Benefits of Using Chinese NEMA CE Sheets in the Middle East

Electrical insulation materials like NEMA CE sheet have to deal with special problems because of the difficult weather conditions that are common in Middle Eastern factories. Extreme humidity, high temperatures, and chemical contact all call for materials that work very well, and Chinese NEMA CE sheets always do.

Operational benefits go beyond initial cost savings. They include fewer repairs and replacements and longer machine life. The better chemical resistance qualities keep the material from breaking down when it comes into contact with common industry chemicals and natural pollutants in the area.

Environmental performance benefits include high resistance to UV rays and thermal stability, which keep structures intact even when exposed to strong sunlight and high temperatures. These traits are especially useful for electricity setups outside and industry equipment that is in full sunlight.

There are many ways to lower costs that add up to economic gains. Less expensive materials have a direct effect on project budgets, and less frequent repair needs mean lower operating costs over the life of the equipment. Longer repair times cut down on production slowdown and the lost revenue that comes with it.

One benefit of technical help is that it gives you access to engineering knowledge and application advice from Chinese providers. A lot of companies that make things hire technology experts who know how to meet the needs of Middle Eastern businesses. These experts help with creation and fixing problems throughout the lifespan of the product.

Company Introduction and Product Services

J&Q is known as a top company that makes and sells high-quality electrical shielding materials. They focus on making NEMA grade laminates for industrial use. We have more than twenty years of experience making insulation sheets and more than ten years of experience doing business internationally.

Our production skills cover the full range of electrical insulation goods, including NEMA CE sheet, from standard NEMA grades to unique laminates that are made just for you. Advanced sealing machinery and precision cutting centers are used in factories to make sure that materials meet the strictest requirements.

Comprehensive testing labs for checking electrical, mechanical, and chemical properties are part of quality management systems. Every batch of products is put through a lot of tests to make sure they meet all the standards and customer needs.

For foreign buyers, our combined transportation services make the supply chain process easier. Logistics operations held by the company schedule shipping, customs clearing, and deliveries so that products are always available and wait times are cut down.

Conclusion

People in the Middle East prefer Chinese NEMA CE sheets because they are a good balance of quality, performance, and cost that meets the region's strict industry needs. Chinese producers have consistently shown that they can make electrical shielding materials that work well in tough conditions while keeping prices low. Chinese providers are the best choice for Middle Eastern buying teams because they can make advanced products, have thorough quality systems, and offer a wide range of customization options. When you combine excellent professional skills, dependable supply lines, and helpful customer service, you get a strong value offer that goes beyond the initial cost and includes total ownership benefits throughout the duration of a product.

FAQs

What rules do Chinese NEMA CE sheets follow around the world?

NEMA CE sheets made in China meet a number of foreign standards, such as IEC 60893, ASTM D709, and different UL requirements. Leading makers keep their ISO 9001 and ISO 14001 environmental management system standards up to date. According to standard practices in the business, products are tested for their electrical traits, industrial strength, and chemical protection.

How can buying teams make sure that the electrical insulation materials they buy from Chinese sellers are real and of good quality?

To check the quality, you need to ask for a lot of paperwork, like material test certificates, factory licenses, and reports of the quality management system. Reliable providers give test results that are special to each batch and cover electrical qualities, mechanical features, and chemical protection performance. To back up what suppliers say, third-party inspection services can check out factories and test products.

How long does it usually take to ship electrical insulation sheets from China to places in the Middle East?

Depending on the details of the order and the way of sending, standard wait times are between 15 and 30 days. Freight by sea usually takes 20 to 25 days to get to big places in the Middle East. For urgent needs, air freight cuts the time it takes to get there to 5 to 10 days. Depending on how complicated they are, custom specs or special sizes may add 7–14 days to the production time.

Partner with J&Q for Premium Solutions for NEMA CE Sheets

J&Q is ready to be your reliable source for NEMA CE sheets, providing you with top-notch quality and full support for all of your electrical shielding needs. Our 20 years of experience making high-quality products and our track record of success in foreign trade mean that you can always get products and professional help from us.

Our dedication to quality starts with choosing the raw materials and ends with the final review. This ensures that the materials we use work above and beyond what is expected in the tough industrial settings of the Middle East. You can be sure that every package is safe because of our thorough testing and quality control methods.

Custom engineering services can meet the specific needs of a product by providing custom measurements, changed material systems, and better performance qualities. Tech support teams work directly with customers to come up with the best answers for their unique business problems.

Competitive prices and a variety of buying choices make it possible to handle both big jobs and routine upkeep. Our combined transportation skills make sure that delivery times are always met and that foreign goods go through customs processing more quickly.

Are you ready to enjoy the benefits of high-quality electrical insulation products backed by top-notch service? Email us at info@jhd-material.com to talk about your needs and get full quotes.

References

National Electrical Manufacturers Association. "Industrial Laminating Thermosetting Products Standard." NEMA LD 3-2005, Arlington, VA.

International Electrotechnical Commission. "Insulating Materials - Industrial Rigid Laminated Sheets." IEC 60893-3-1:2003.

Middle East Industrial Development Report. "Electrical Infrastructure and Materials Demand Analysis 2023." Regional Industrial Council Publications.

Chen, W., and Li, S. "Advanced Manufacturing Technologies in Electrical Insulation Materials Production." Journal of Industrial Materials Engineering, Vol. 45, No. 3.

Global Procurement Research Institute. "Supply Chain Analysis: Electrical Insulation Materials in Emerging Markets." International Trade Publications, 2023.

Zhang, M., et al. "Quality Management Systems in Chinese Manufacturing: Case Studies in Electrical Materials Production." Manufacturing Excellence Quarterly, Vol. 28, No. 2.