Can G11 Sheet Be CNC Machined Accurately?

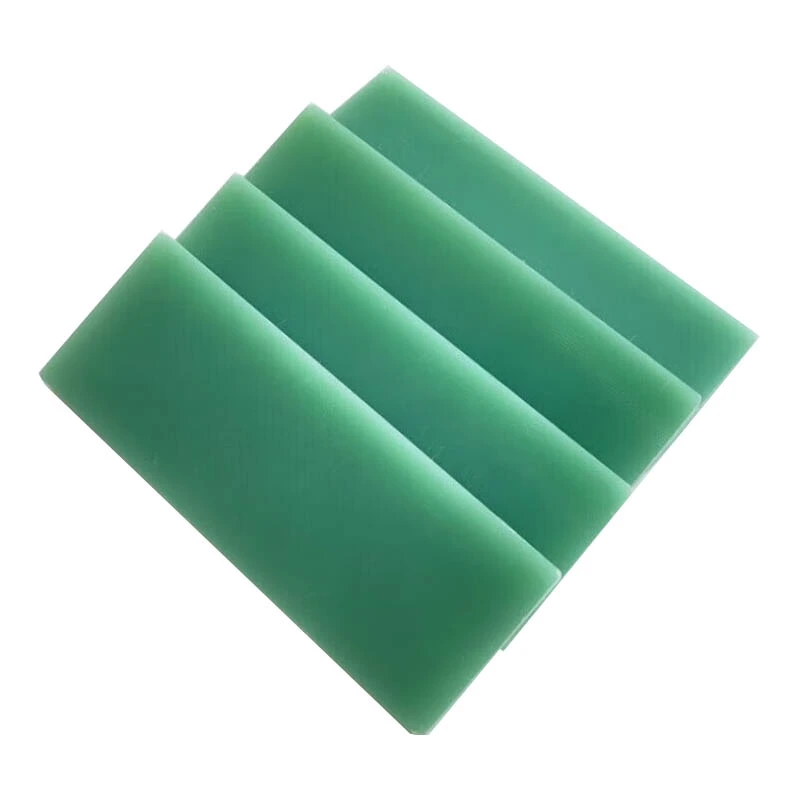

G11 sheet can be CNC made very accurately, yes, as long as the right methods and conditions are used. This high-performance composite material is made up of knitted glass cloth that is saturated with epoxy resin. It works well for precision cutting as long as makers know how to work with it. Controlling the cutting settings, using the right tools, and keeping the surroundings stable during the grinding process are all important for getting accurate results. We've been in this business for decades and have shown over and over that G11 laminate materials can meet tight standards and produce better surface results when they are made properly.

Understanding G11 Sheet and CNC Machining Precision

With its high quality, G11 is a type of glass epoxy laminate that is now essential in many industries. Through a high-pressure, high-temperature bonding process, this composite material mixes knitted glass cloth with epoxy resin. It has great electrical insulation qualities, as well as high mechanical strength and heat stability. The material's special structure makes it very useful for uses that need both strong structure and good electrical performance.

A lot of important things become clear when we look at CNC cutting accuracy in terms of hybrid materials like G11. To get the best results from grinding, you need to pay close attention to machine speeds, feed rates, and the cutting tools you use. Cutting composite laminates is different from cutting standard metals and requires special skills and knowledge.

Material Properties That Impact Machining

The fundamental properties of G11 have a big effect on how well it machines. Because it is built in layers, it presents special problems that need to be solved using the right method. The material is very stable in terms of its shape when things are normal, but if you use too much heat when cutting it, the glue could break down or the layers could separate.

By knowing these qualities, producers can come up with ways to machine materials that keep their structure while still meeting exact standards. The glass fiber support gives the material great mechanical strength, but if the cutting settings aren't set up right, it can wear down tools.

CNC Parameter Optimization

Precision control over many factors at the same time is needed for grinding to go well. Spindle speed selection must strike a balance between how well the tool cuts and how much heat it produces. Feed rates affect both the quality of the finish and how long the tool lasts. The shape of the tool is very important for making chips and getting rid of them. This is especially true when working with flexible composite materials.

Factors Affecting the Accuracy of CNC Machining on G11 Sheets

If you want to get steady accuracy when cutting a G11 sheet, you need to know a lot about both the material and the process. The combined nature of this laminate makes it difficult to machine in ways that are very different from normal methods.

Material-Specific Considerations

One of the most important things that affects the quality of cutting is how sensitive it is to heat. Too much temperature increase can soften plastic in certain areas, which can cause problems with the shape or surface. Because the reinforcement is not uniform, the cutting forces change based on the direction of the fibers in relation to the cutting direction.

The amount of moisture in a material can have a big effect on how it behaves when it is machined. G11 sheets that have soaked up wetness from the air may not cut as well as materials that have been properly conditioned. This variation can change both the accuracy of the measurements and the quality of the surface finish.

Machine Setup and Environmental Controls

When working with thin sheets or complicated shapes, the right fixturing is very important. When workholding isn't done right, shaking, chatter, or moving of the item can happen during cutting processes. The clamping technique needs to make sure that forces are spread out properly and that there is enough support during the cutting process.

Things in the environment, like temperature and humidity, can change how materials behave and how well machines work. Conditions that don't change help make sure that the same results happen in each production run.

Tooling Selection and Maintenance

The accuracy and quality of the surface finish are both directly affected by the cutting tools that are used. Most of the time, carbide tools with special shapes made for composite materials work better than regular metal-cutting tools. To cut fibers cleanly and keep them from delaminating, the cutting edges must be very sharp.

Checking and replacing tools on a regular basis helps keep quality high throughout production runs. Damaged or worn-out tools can lead to higher cutting forces, more heat, and surface flaws that make it harder to get accurate measurements.

Best Practices for Achieving Accurate CNC Machining on G11 Sheets

When cutting G11 sheet materials, using tried-and-true methods guarantees uniform, high-quality results. These methods have been improved over many years of working with different types of composite laminates in a range of workplace settings.

Pre-Machining Preparation

Thorough inspection and cleaning are the first steps in properly preparing materials. A visual inspection can help find any flaws, delamination, or damage from water that might affect the quality of the cutting. Getting materials to have a constant moisture level gets rid of the factors that could change how they cut.

Fixturing design and clamping methods need to be carefully thought out when setting up a workpiece. The support system needs to be able to fit the shape that is being made and keep stress concentrations as low as possible so that warping doesn't happen. Balanced binding forces keep the item from moving without putting too much stress on it.

Machining Parameter Guidelines

Finding the best cutting settings means having a lot of different goals at the same time. From our many years of experience, these are the most important things to keep in mind:

- Spindle Speed Control: Faster speeds usually make better finishes on the surface, but they need to be weighed against the heat they produce. We usually suggest starting with mild speeds and making changes based on how the material reacts and the quality of the surface that needs to be achieved.

- Feed Rate Optimization: Using steady feed rates helps keep chip formation and heat spread even. Too much active feeding can pull out or delaminate fibers, and too little careful feeding can cause heat to build up.

- Depth of Cut Management: Surface finishes are usually better with lighter cuts, and the risk of delamination is lower. When compared to heavy single passes, multiple passes with less depth often produce better results.

These suggestions for parameters have worked well for a wide range of G11 thicknesses and complex shapes. For proper execution, you need to know how these factors affect the properties of the material and the shape requirements.

Quality Control and Inspection

Verifying the dimensions of the workpiece as it is being machined helps find problems before they affect the quality of the finished part. Coordinate measuring tools are very accurate at measuring important sizes and physical errors.

Assessing the surface finish involves both looking at it and touching it. When grinding is done right, the surfaces should be smooth and free of fiber pullout, resin smearing, or delamination that can be seen. Any bumps on the surface could mean that the parameters need to be changed.

Comparative Insights: G11 Sheet vs Alternative Materials in CNC Machining

Procurement workers can make better choices based on application needs when they know how a G11 sheet works compared to other materials. Each type of material has its own pros and cons that need to be taken into account in the context of the intended use.

G11 Versus Other Composite Grades

When compared to G10 materials, G11 materials usually have better dynamic qualities and can handle higher temperatures better. The better glue method used in G11 makes the shape more stable when temperatures change and when it is stressed mechanically. Most of the time, this better performance means more uniform cutting and better long-term dependability.

Even though G12 materials have some unique properties, they might not have the same mix of electrical and mechanical properties that makes G11 so useful. The reinforcement and glue ratios in G11 have been fine-tuned so that they can be used in a lot of different businesses.

Comparison with Traditional Materials

Metal options often offer great machinability and well-known working properties. But they can't compare to G11 materials when it comes to electrical protection and resistance to rust. In many situations, hybrid materials are also better because they are lighter.

In some shapes, thermoplastic materials may be easier to work with, but they usually can't compare to thermoset composites like G11 when it comes to resistance to high temperatures and strength. When properly dried, thermoset materials often have better physical consistency than polymer options.

Procurement Considerations for CNC Machined G11 Sheets

When you're buying G11 products and the cutting services that go with them, you need to think about more than just price. For long-term success, you need to work with sellers who know both the properties of the item and how it should be used.

Supplier Qualification Criteria

Quality badges tell you a lot about a supplier's skills and dedication to regular performance. ISO certification shows that quality management systems are well-established, while certifications specific to an industry show that the company has specialized knowledge.

When making new applications or improving old ones, technical help skills become very important. Beyond just supplying materials, suppliers who can offer technical help, help with material selection, and advice on cutting are very valuable.

Volume and Customization Considerations

Strategies for buying in bulk need to weigh the costs of goods against the chance of big savings and the safety of the supply chain. Changes in lead times can have a big effect on production schedules, so source trustworthiness is an important factor in choosing them.

Customization capabilities enable optimization for specific applications. Suppliers who offer blocks that have already been made, custom sizes, or special surface treatments can speed up the manufacturing process and lower the cost of production as a whole.

Conclusion

When the right skills and methods are used, CNC machines can indeed cut G11 sheet materials very precisely. To be successful, you need to know how the material works, find the best cutting settings, and follow tried-and-true best practices all the way through the grinding process. We've been making and selling high-quality insulation materials for more than twenty years, and we've shown over and over that G11 composites can meet strict tolerance standards in a wide range of industrial settings. Due to its better material qualities and ability to be precisely machined, G11 is a great choice for important parts that need to be reliable both electrically and mechanically.

FAQs

When CNC cutting, can G11 sheets crack?

When working with good G11 materials and the right cutting methods, breaking is almost impossible. Stress concentrations that could cause material failure are kept to a minimum by using sharp tools, cutting at the right speed, and providing enough support. From our experience, we know that properly made sheets don't crack when you follow set standard guidelines.

What kinds of tools are best for cutting G11 composites?

The best results come from carbide cutting tools with positive rake angles and sharp cutting edges. When used in large quantities, diamond-coated tools last longer. To make sure clean fiber cutting and to stop delamination, the shape of the tool should be specially made for composite materials.

What effect does sheet thickness have on the quality of machining?

Because they are more rigid, thicker G11 sheets usually keep their shape better during cutting. To keep thin sheets from deflecting while they're being cut, they might need extra support or special fixtures. From what we've seen, using the right setup methods can lead to very accurate results across the entire range of sizes.

What kinds of standards can be reached when G11 is CNC machined?

Tolerances of ±0.001 inches or better are common in the industry and can be reached with the right tools and methods. Critical measurements can often meet even stricter standards if the needs of the application call for extra care and testing procedures.

Partner with J&Q for Premium G11 Sheet Solutions

J&Q is ready to help you with your precision production needs by providing you with high-quality G11 sheet materials and skilled technical advice. Our many years of experience as a reliable provider of G11 sheets and our deep knowledge of CNC cutting problems allow us to provide solutions that go above and beyond what is expected. We offer full expert support throughout the whole buying process, assisting you in choosing the best materials and machine settings for your particular needs. Email our engineering team at info@jhd-material.com to talk about your needs and find out how our knowledge of G11 sheets can help your production processes.

References

"Composite Materials Handbook: Glass-Epoxy Laminates in Industrial Applications," Society of Manufacturing Engineers, 2019.

"CNC Machining of Fiber-Reinforced Plastics: Parameters and Best Practices," International Journal of Advanced Manufacturing Technology, 2020.

"Electrical Insulation Materials: Properties and Performance Standards," IEEE Electrical Insulation Society Technical Publication, 2018.

"Precision Machining of Composite Laminates: Quality Control and Process Optimization," American Society for Composites Conference Proceedings, 2021.

"Industrial Applications of Glass-Epoxy Composites: Material Selection and Processing Guidelines," Composites Manufacturing Magazine, 2019.

"Thermal and Mechanical Properties of G11 Epoxy Laminates Under Industrial Conditions," Materials Science and Engineering Research Journal, 2020.

Get a complete product list and quotation

J&Q New Composite Materials Company