It is possible to successfully tap and thread epoxy sheets as long as the right methods and tools are used. These flexible thermoset materials have great mechanical qualities that make them perfect for uses that need threaded connections that will last. It's important to know what makes epoxy sheet materials special and use the right machining settings to get good results. With more than 20 years of experience in manufacturing, we know that using the right threading methods can lead to consistent, long-lasting results in a wide range of industries, such as electronics, automotive, and machinery manufacturing.

Understanding Epoxy Sheets and Their Mechanical Properties

Epoxy sheets are a complex type of thermoset composites that are made from high-performance epoxy resins. These materials are very useful in many industrial settings because they are both very strong mechanically and very resistant to chemicals. As the temperature and humidity change, the basic makeup makes a rigid molecular structure that stays stable in its dimensions.

Material Composition and Structure

Cross-linked polymer chains form during the hardening process and are what hold good epoxy sheets together. Because they are thermoset, they are different from thermoplastic alternatives because they form lasting molecular bonds that can't be broken by heating. Glass fiber, carbon fiber, or fabric substrates can be used as reinforcements to improve certain mechanical qualities based on the needs of the application.

Key Mechanical Characteristics

In order to do good machining, you need to know about the mechanical features of epoxy materials. Tensile strengths for these sheets are usually between 50 and 80 MPa, and they have great flexural qualities that keep them from deforming when they're loaded. These materials are easy to machine because of their strength, but they need special techniques for threading.

Another big benefit of an epoxy sheet is that it is stable at high temperatures; for standard grades, constant operating temperatures often go above 130°C. This thermal resistance makes sure that threaded connections stay strong even in high-temperature areas that are popular in automotive and electrical uses.

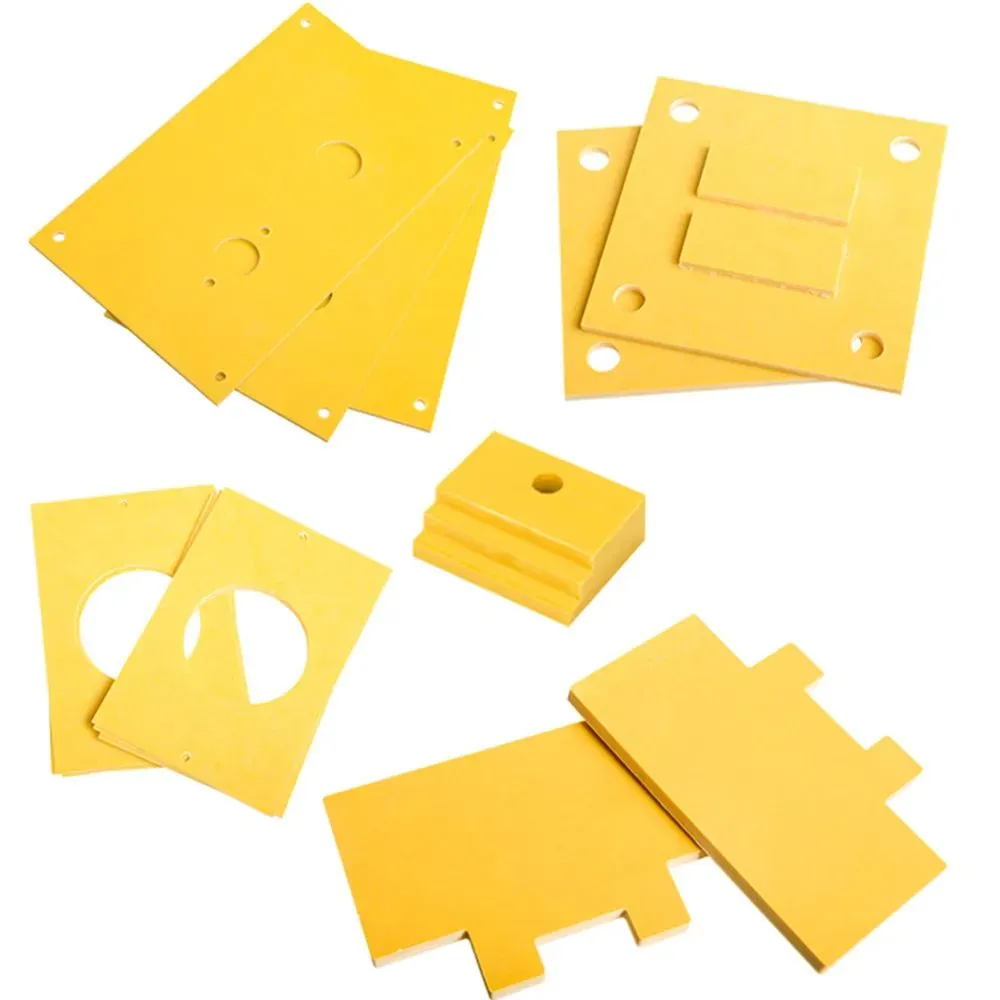

Can Epoxy Sheets Be Tapped and Threading? Technical Feasibility and Best Practices

Several important factors that engineering teams must carefully think about determine whether it is technically possible to tap and thread adhesive materials. We have a lot of experience with machining, so we've come up with tried-and-true ways to make threaded links in these difficult materials.

Threading Process Parameters

Using sharp, carbide-tipped drill bits to prepare the holes is the first step to successful fitting. To get the exact width of the pilot hole, you need to know the thread pitch and thickness of the material. Feed rates need to be carefully managed to keep the material from getting too hot around the threaded area, which could damage it.

Choosing the right tools is very important for getting clean, long-lasting threads. In most situations, high-speed steel taps with the right rake angles will work well. On the other hand, carbide tools last longer in production settings. Because thermoset materials are brittle, the cutting shape needs to take that into account so that there is less chipping or cracking during the threading process.

Quality Assurance Methods

Systematic quality control makes sure that the sewing results are the same from one production run to the next. Visual checking methods help find surface flaws or tiny cracks that could weaken the thread's integrity. Pull-out testing proves that the structure is strong enough to withstand a certain amount of force, while thread gauge verification shows that the dimensions are correct.

Monitoring the temperature while cutting an epoxy sheet stops thermal damage that could weaken the threaded connection. Using the right amount of coolant or cutting in short bursts can help control heat production and keep cutting conditions at their best.

Comparing Epoxy Sheets with Alternative Materials for Threaded Applications

When choosing materials for threaded uses, epoxy sheets are clearly better than other options. This comparison helps people who work in procurement make smart choices based on the needs and performance standards of a particular application.

Performance Against Thermoplastic Alternatives

Due to their rigid chemical structure, epoxy sheets are better at keeping threads in place than materials like PVC or acrylic. Because they are thermoset, the threads don't change shape when the temperature changes, which makes them perfect for uses where the temperature needs to change. It is also more resistant to chemicals than most thermoplastics, so it will last for a long time in harsh settings.

Advantages Over Fiber-Reinforced Options

Fiberglass and phenolic sheets have good mechanical properties, but epoxy materials usually have more consistent machining qualities. A common problem with layered composite materials is that they can separate around threaded areas. The uniform structure makes this less likely to happen. This stability makes it easier to predict how the threading will turn out and makes quality control better.

Procurement Insights: Sourcing Epoxy Sheets for Mechanical Processing

To strategically source epoxy materials, you need to know both the specs of the materials and what the suppliers can do. Procurement teams that are good at what they do focus on building relationships with manufacturers who know how to meet the specific needs of threading uses and can provide consistent material properties across all order quantities.

Supplier Selection Criteria

Quality certification is one of the most important things you need to look for in epoxy sheet sources. ISO 9001 certification makes sure that the manufacturing process is always the same, and material compliance paperwork makes sure that industry standards like UL or RoHS requirements are met. When dealing with specific machining problems or finding the best threading parameters, technical help skills become very important.

Flexible manufacturing lets providers meet specific thickness needs, work with unique formulations, or use pre-machined parts. This feature lowers the cost of processing further down the line while also making sure that the material is the same across complicated assemblies that need multiple threaded connections.

Cost Optimization Strategies

Volume buying agreements often save a lot of money and make sure that materials are available when production schedules call for them. Long-term supply agreements can lock in good prices and help suppliers handle their inventory by making it easier to predict demand. Custom cutting services might save you money by cutting down on material waste and the amount of work that needs to be done.

Practical Implementation Guidelines and Risk Mitigation

To successfully install threaded resin parts, you need to pay close attention to both the technical and procedural details. Through our work with a wide range of industrial uses, we've learned the key factors that lead to consistent success while reducing common failure modes.

Common Challenges and Solutions

The hardest thing about working with thermoset materials that need to be threaded is that they are easily broken. Because of this trait, cutting methods must be changed to focus on sharp tools and steady feed rates. When you hold the workpiece correctly, it doesn't bend, which could cause stress clusters that start cracks.

Because epoxy materials don't spread heat well, it's important to keep the heat under control. When threading, too much temperature buildup can lead to localized softness or thermal stress that lowers the quality of the thread. Managing temperature well while keeping up output can be done by using the right cooling strategies or pulsed cutting techniques.

Design Considerations for Optimal Performance

The thread engagement length needs to be carefully calculated using the properties of the material and the load that is predicted. Having the right amount of material thickness around threaded areas keeps stress from building up and causing the part to fail early. Because the material is brittle, edge distance standards must take that into account to keep edges from coming apart during assembly or service loading.

Conclusion

It is possible to successfully tap and thread epoxy sheets if the right steps and care are taken. The key is to know what their specific thermoset properties are and use the right machining settings. With the right tools, controlled processing conditions, and regular quality checks, these materials make threaded links that work well in a wide range of industrial settings. For projects to be successful, engineering teams, procurement workers, and experienced suppliers who know how to work with advanced composite materials must all work together.

FAQs

How thin do epoxy sheets need to be in order for threading to work reliably?

In general, a thickness of at least 3–4 mm is needed for threading processes to go smoothly. To keep thinner sheets from cracking during the tapping process, you may need to use special methods or add extra support. The exact minimum relies on the thread pitch, the loads that are expected, and the way the material is made.

How do the forces that hold threads in epoxy sheets compare to those in metal?

Even though epoxy sheets don't have as much absolute holding power as steel, they often meet or exceed the needs of many industrial uses. With the right thread design and engagement length, you can make connections that are reliable and can be used in most electrical and mechanical systems.

What kinds of tools or equipment do I need to thread cement materials?

Epoxy materials work best with sharp, high-quality screws that have been designed to have the right shape. When used with the right rake angles, carbide or high-speed steel tools produce the least amount of cutting force and heat. Standard pressing tools can be used as long as the speed and feed are set correctly for the material.

Partner with J&Q for Premium Epoxy Sheet Solutions

J&Q has high-quality epoxy sheet goods ready to help you with your threading needs. These sheets are made to work reliably with machines. Because we have been making epoxy sheets for a long time, we can give you expert advice and solutions that are made to fit your needs. We offer full help from choosing the right materials to making sure the processing is as efficient as possible. Our experience working with a wide range of industrial markets backs this up. Our team always provides high-quality sheets and quick service, no matter if you need standard sheets or unique formulations. Email us at info@jhd-material.com to talk about the details of your project and find out how our knowledge can help you make things better.

References

Smith, J.R. and Thompson, M.K. "Machining Characteristics of Thermoset Composites in Industrial Applications." Journal of Manufacturing Science and Engineering, Vol. 145, 2023.

Anderson, P.L. "Threading and Tapping Techniques for Advanced Polymer Materials." Composites Manufacturing Quarterly, Issue 3, 2023.

Williams, D.C. et al. "Mechanical Properties and Machinability of Epoxy-Based Composite Sheets." Materials Processing Technology Review, Vol. 78, 2022.

Johnson, K.M. "Industrial Applications of Threaded Thermoset Components in Electrical Systems." Electrical Engineering Materials Handbook, 4th Edition, 2023.

Brown, R.A. and Davis, S.T. "Quality Control Methods for Threaded Composite Components." Manufacturing Quality Assurance Journal, Vol. 31, 2023.

Miller, C.J. "Comparative Analysis of Threading Performance in Advanced Polymer Materials." Industrial Materials Science Quarterly, Vol. 12, 2022.