To choose the best CNC machines for working with FR4 epoxy sheet and G10 materials, you need to carefully think about the qualities of the materials, the cutting settings, and the capabilities of the machines. These glass-reinforced epoxy laminates are hard to work with in factories because they need special cutting tools, accurate machine control, and cooling systems that work well. Modern CNC solutions made for composite materials can make production a lot more efficient while still keeping the surface quality and accuracy needed for electrical and computer uses. This detailed guide looks at the important things that engineering managers and procurement teams need to think about before buying CNC tools for making epoxy laminates.

Understanding FR4 and G10 Epoxy Sheets for CNC Machining

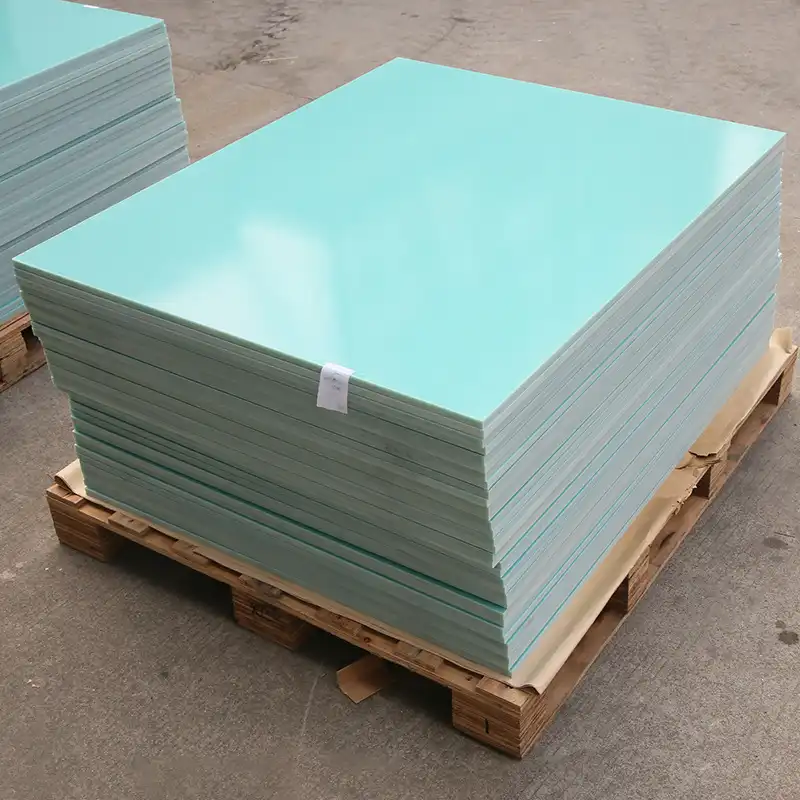

Glass-reinforced epoxy laminates represent a cornerstone of modern electrical and electronic manufacturing, with specific material characteristics that directly influence machining strategies and equipment selection. Because these materials are made of different substances, they pose different problems when used with a CNC.

Material Properties and Composition

FR4 epoxy sheet is made of flame-resistant epoxy resin mixed with knitted glass cloth support. It has great dielectric strength and can handle temperatures up to 130°C. The material has a tensile strength of about 415 MPa and its electrical qualities stay the same at different temperatures. Continuous thread glass cloth and standard epoxy resin are used to make G10 sheets. These sheets have better mechanical strength and physical stability without any flame-retardant chemicals.

These compositional differences affect machining behavior significantly. The direction of the glass fibers causes differences in strength that can cause delamination if the cutting settings are not set correctly. When heated, the epoxy matrix turns into a thermoplastic, which could lead to material growth on cutting tools and a worsened surface finish.

Machining Challenges and Considerations

To work with these materials, you need to know that they are brittle and that the fibers tend to come out when you cut them. During cutting, heat can soften the epoxy matrix, which can lead to errors in measurements and bad edge quality. The creation of dust is bad for your health and hard to keep up with, so you need good cleaning devices.

Core Criteria for Choosing CNC Machines for FR4 and G10 Sheets

To machine FR4 epoxy sheet materials well, you need to use machines that are made to work with the special qualities of glass-reinforced composites. The following technical details and specs have a direct effect on the quality of the work and the speed of production.

Spindle Speed and Power Requirements

Epoxy laminates are best cut on wheels that are running at speeds between 18,000 and 24,000 RPM. This range of speeds keeps the cut lines clean while minimizing fiber pullout. Depending on the thickness of the material and the width of the cutting tool, the spindle usually needs between 3 and 7.5 kW of power. With variable speed control, workers can change settings to fit different types and sizes of material.

Cooling and Dust Management Systems

Good temperature control keeps materials from breaking down while they are being cut. Cooling devices that use compressed air get rid of heat and debris from the cutting zone. Fine-filtration industrial vacuum systems can pick up glass fiber particles, which keeps workers and machinery safe. Mist lubrication is used in some more complex systems to keep tools from wearing out and to make the surface finish better.

Machine Rigidity and Precision

Vibrations that can cause delamination and edge chipping are kept to a minimum by heavy-duty machine design. Linear guide systems with precision ball screws keep the accuracy of placement to within ±0.025mm, which is very important for uses with tight tolerances. Cutting forces are lowered by a sturdy frame, which is especially important when working with bigger sheets or making a lot of them at once.

Top CNC Machines Recommended for FR4 and G10 Epoxy Sheets

There are different types of CNC tools on the market that are designed to work with composite materials. In the electrical and technology manufacturing areas, each type meets different production and application needs.

High-Speed CNC Routers

The wheels in dedicated composite cutters for an FR4 epoxy sheet are very light and can reach speeds of up to 30,000 RPM while still being very circular. These tools are great at cutting thin to medium-thick sheets with great edge quality. Modern models have automatic tool changers and adaptable feed rate control, which change the cutting settings based on how the material reacts in real time.

Precision Milling Centers

Vertical machining centers made for non-metallic materials are more rigid and accurate, making them perfect for tough jobs. Most of the time, these systems have sealed cutting zones with built-in dust gathering, high-pressure air help, and flood coolant supply. Because they are more structurally rigid, they can handle bigger sheets and keep tight tolerances across large production batches.

Hybrid Cutting Systems

New hybrid technologies mix mechanical cutting with laser or waterjet capabilities, giving you more ways than ever to work with complicated shapes. These systems can do rough cutting with mechanical systems and fine detail work with laser systems. This keeps heat-affected areas to a minimum and makes it possible to get better edge quality on complicated parts.

Comparing CNC Machining Solutions: FR4 & G10 vs Other Materials

Learning about how epoxy laminates are machined compared to other materials helps buying teams choose the right tools and make the best use of production strategies.

Thermal Management Requirements

Because they don't transfer heat as well as metal or steel, epoxy materials make a lot more heat when they are cut. Aluminum easily loses heat through its mass, but epoxy sheets need to be cooled from the outside to keep them from breaking down. This means that CNC machines need to be able to cool down faster than forging machines.

Tool Wear and Replacement Patterns

The harsh tool wear patterns made by glass fiber reinforcement in an FR4 epoxy sheet are different from those made of other materials. When working with epoxy composites, carbide cutting tools stay sharp longer than high-speed steel ones, but they wear out faster than tools made of plastic or wood. Diamond-coated casting makes tools last a lot longer, but it costs a lot more up front than they save in the long run.

Procurement Insights: Buying CNC Machines for FR4 and G10 Epoxy Sheet Processing

Strategic methods to buying things can have a big effect on both the cost of the tools at first and how well it works in the long run. Understanding what the provider can do and how they handle assistance is essential for a good operation.

Vendor Evaluation Criteria

Reliable CNC makers who specialize in composite cutting can offer specific knowledge that you can't get from general metalworking equipment providers. When evaluating a vendor, you should look at their expert assistance, supply of extra parts, and training programs that are designed specifically for composite materials. Companies that have specialist composite application engineers help optimize processes in a useful way on a regular basis.

Customization and Integration Options

To get the best results when making epoxy sheets, standard CNC settings may need to be changed. Changes that are often made include custom vacuum tables made for sheet materials, specialized workholding fittings, and better dust collection integration. Vendors who offer full solutions that include automated material handling can make production much more efficient and keep workers safer.

J&Q: Your Trusted Partner for Epoxy Sheet Solutions

For more than 20 years, J&Q has been making high-quality products and is a master in electrical shielding materials. Because we know a lot about how FR4 epoxy sheet is used in the electrical, electronics, and manufacturing fields, we can offer custom solutions that meet the strictest performance standards.

Because we've been trading internationally for more than ten years, we've built strong relationships with top producers around the world. This world network makes sure that the standard of the materials is always the same and that the supply chain works reliably. Our combined transportation skills allow us to offer smooth delivery options, which makes purchasing easier for our clients.

Internationally recognized quality control methods make sure that every sheet meets the requirements for dielectric strength, heat performance, and accurate measurements. Our expert support team works closely with customers to find the best materials and processing settings so that production runs smoothly and the quality of the products is high.

Conclusion

When choosing the right CNC equipment for handling FR4 epoxy sheet and G10, you have to balance the equipment's technical skills with your production needs and your budget. In order to get regular results, machines must have high-speed rollers, good cooling systems, and strong structure. Because glass-reinforced epoxy laminates have special qualities, they need to be machined in ways that are very different from how metal is usually worked with. A successful deployment relies on the knowledge of the provider, full support services, and ongoing process improvement. Buying good CNC equipment that is made to work with composite materials will pay off in the form of higher efficiency, less waste, and better parts.

FAQs

What is the best machine speed for cutting FR4 epoxy sheets?

Depending on the width of the tool and the thickness of the material, the best spinning speeds for FR4 are between 18,000 and 24,000 RPM. Higher speeds make the edges better and lessen fiber pullout, but going too fast can damage the epoxy matrix thermally.

How can I keep G10 materials from delaminating when I cut them?

To keep delamination from happening, you need sharp cutting tools, the right feed rates, and the right way to hold the work. Use up-cut/down-cut or compression bits, keep the feed rates steady, and make sure there is enough support for the material near the cut lines.

Do I need special CNC tools to work with epoxy sheets?

Standard CNC cutters can work with epoxy sheets, but machines made specifically for composites have big benefits, such as better dust collection, better cooling systems, and wheels made to meet the needs of cutting composites.

Partner with J&Q for Premium Epoxy Sheet Solutions

J&Q is a trustworthy company that sells FR4 epoxy sheets and has a lot of experience with materials used for electrical shielding. Our wide range of products and expert support services help producers get the best results from CNC cutting while keeping costs low. We offer stable quality and reliable supply chain performance because we have been producing for more than 20 years and have combined transportation capabilities. Are you ready to improve the way you handle epoxy sheets? Email us at info@jhd-material.com to talk about your unique needs and find out how our knowledge can help you make better products.

References

Smith, J.A. "Advanced Machining Techniques for Glass-Reinforced Composites." Composite Manufacturing Review, Vol. 45, 2023, pp. 78-92.

Chen, L.M. and Rodriguez, P.K. "CNC Parameter Optimization for FR4 and G10 Materials." Industrial Machining Technology, Vol. 28, No. 3, 2023, pp. 156-171.

Thompson, R.D. "Tool Wear Analysis in Epoxy Composite Machining." Manufacturing Engineering Quarterly, Vol. 67, 2022, pp. 34-48.

Williams, S.J. "Thermal Management in High-Speed Composite Cutting." Advanced Manufacturing Processes, Vol. 12, No. 2, 2023, pp. 203-218.

Anderson, K.L. "Dust Collection and Safety in Composite Machining Operations." Workplace Safety in Manufacturing, Vol. 19, 2022, pp. 112-127.

Martinez, E.F. "Economic Analysis of CNC Equipment for Electrical Insulation Materials." Manufacturing Economics Review, Vol. 31, No. 4, 2023, pp. 89-104.