Finding good ways to keep the dust under control while CNC-machining fiberglass sheets is one of the biggest problems in modern factories. Managing floating particles during precision cutting operations is important for worker safety and product quality as composite materials become more popular in industries like electronics, cars, and factories. Because fiberglass sheets have special qualities, they need to be machined in a certain way to keep accuracy and reduce dust production. When buying managers and engineers understand these solutions, they can improve their operations while still following safety rules and keeping production cycles as cost-effective as possible.

Understanding Dust Generation in CNC Machining of Fiberglass Sheets

The complicated nature of fiberglass composite materials makes CNC cutting tasks more difficult. These engineering materials are made up of glass fibers that are inserted in polymer resin structures. This gives them unique properties that directly affect how dust forms and how it is controlled.

What Is Fiberglass Sheet and Its Properties Related to Dust Formation?

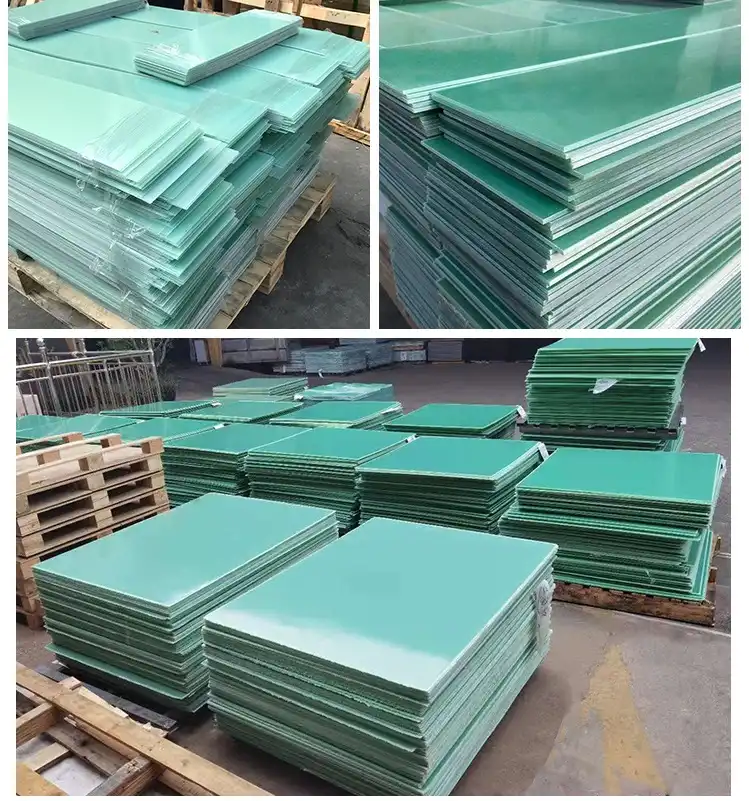

Fiberglass sheet materials are man-made alloys that are reinforced with woven glass fibers in thermosetting resins. From light electrical insulation panels to heavy-duty structure laminates, the densities of the different sheet types vary. When the material is machined, the glass fibers break down into tiny bits, and the resin matrix turns into fine polymer dust. This two-part dust profile needs special collection systems that can handle both rough glass particles and polymer pieces that could be dangerous. Because these composites are made up of layers, cutting them can release dust at different rates, based on how the fibers are arranged and how the resin is spread out across the thickness of the material.

Causes of Dust in CNC Machining Processes

A lot of different mechanical processes, which depend on the cutting settings and tool choice, cause dust to be made during CNC machining. High-speed spinning of the cutting tools causes friction against the composite surface, which breaks down resin parts thermally and breaks glass fibers mechanically. Feed rates and spinning speeds have a direct effect on the size distribution of particles. For example, faster cutting usually makes smaller dust particles that stay in the air longer. Patterns of tool wear affect how much dust is made because dull cutting edges tear materials more than they cut them cleanly. The way coolant systems and dust creation work together is also very important. If you don't use coolant correctly, it can turn into slurries that clog extraction systems, and if you don't cool enough, too much thermal dust is made.

Health and Safety Concerns Associated with Fiberglass Dust

Fiberglass particles in the air are known to be harmful to health and need to be dealt with right away in industrial settings. When they come into touch with skin, eyes, or lungs, glass fiber bits can be irritating. Long-term exposure to fine glass dust can cause more major breathing problems, so workers need to be protected by filtration that works well. Regulatory bodies have set limits on how much glass fiber dust people can be exposed to. These limits are usually found by measuring the normal amounts of dust in the air over time. Besides the immediate health risks, dust accumulation makes cleaning difficult and could be a fire risk in electricity settings. To stay in line with OSHA rules, manufacturing facilities must use complete dust control plans to protect worker health and make sure products meet quality standards.

Proven Dust Control Techniques for Fiberglass Sheet CNC Machining

Several methods are used in modern factories to keep dust levels down during fiberglass cutting operations. From simple collection methods to complex, unified systems, the change shows that people are becoming more aware of both safety and quality standards for production.

Traditional Dust Control Methods and Their Limitations

Common ways to control dust when machining a fiberglass sheet include using wet grinding methods and putting simple vacuum collection systems near the cutting areas. During cutting processes, cooling or water mist is used to stop bits from flying around. This is called wet machining. This method works for bigger particles, but it can be hard to get rid of dirty water, and it might not catch the smallest particles that are the most dangerous to your health. Even the most basic shop vacuums can't move a lot of air and don't filter well enough for tiny glass fibers. These old ways of doing things often can't handle the constant demands of operation and need to be serviced often to keep working well. The problems become especially clear in places where a lot of stuff is made and the amount of dust made is too high for simple collection systems to handle.

Advanced Dust Extraction Systems: Features and Principles

Modern dust extraction systems use high-efficiency particulate air filtering technology that was made just for working with composite materials. The changeable airflow settings on these systems change the pressure power based on the cutting factors and the qualities of the material. Multi-stage filtering separates large particles and collects small particles. This makes the filter last longer while keeping its performance constant. Built-in sensors keep an eye on how well the system is working and let workers know when repair is needed before the system stops working as well. Modern systems have automatic filter cleaning features that keep the airflow at its best without stopping production. By putting extraction ports near where the cutting is happening, controlled airflow patterns are made that catch particles where they start before they can fly through the air and spread to other parts of the area.

Practical Case Studies: Successful Dust Control Implementations

Some of the biggest names in technology have seen big gains after integrating dust control. One company that makes parts for cars cut the amount of particles in the air by 85% after putting in high-velocity extraction systems with special fans placed at the right angles around their CNC machines. A company that makes power distribution equipment got the same results by combining downdraft tables with overhead extraction systems. This made two catch zones that could handle parts of different sizes and angles. These methods show consistent results across a range of production rates and levels of part complexity. This proves that the money spent on advanced dust control technology will pay off in the long run.

Selecting the Best Fiberglass Sheets and Equipment for Lower Dust Production

Material choice and machine efficiency work together to cut down on dust production at the source. By knowing how the qualities of a material affect the factors used for its cutting, you can make smart choices that boost both safety and productivity.

Comparison of Fiberglass Sheets with Alternative Materials from Dust Perspective

Fiberglass mixtures make more complicated dust patterns than materials that are all the same, like steel or aluminum. In metal cutting, chips are always the same size, but when you work with composite materials, you get a mix of particle types that need special care. Phenolic laminates make dust in a similar way, but because their resin systems are more fragile, they usually make more of it. Composites made of epoxy, like FR4, tend to make dust particles that stick together more, which can cause filters to clog up more quickly than composites made of polyester. Knowing these differences helps buying teams choose the right materials for each job while taking into account the overall cost of dust control. The trade-offs between how well a material works and how much dust it makes affect both the short-term costs of cutting and the long-term costs of running the business.

Choosing Fiberglass Sheet Thickness and Composition for Optimized Machining

The amount of dust made by CNC processes when cutting a fiberglass sheet is directly related to the thickness of the material being cut. For example, cutting thicker materials usually requires more aggressive settings, which make more particles. It might be possible to cut thinner sheets more quickly and with less dust, but they might not be as strong in the end application. Changes in the amount of resin in different composite types affect both the way dust behaves and how machines work. Materials with a lot of glass make more sharp dust that needs strong filtration systems. On the other hand, resin-rich composites may make dust that sticks to filters through heat adhesion and clogs them up. Finding the best material for a production setting means balancing these material properties with the needs of the application and its ability to control dust.

Recommended CNC Machinery and Tooling for Minimizing Dust

Retrofit options aren't as good at controlling dust as CNC machines that come with built-in ports for collecting it. Spindle designs that use through-tool coolant supply help cut down on dust production and improve the quality of the surface finish and tool life. The shape of the cutting tool is very important when it comes to making dust. Sharp, well-designed tools make better cuts that make fewer fine particles. Diamond-coated cutting tools keep their sharp edges for longer, which slows down the buildup of dust that happens as tools wear out. Controlled airflow patterns inside machine casings keep dust out of the cutting zone while still letting the operator add parts and check them. When the right machinery and tools are used together, they have mutual effects that make the benefits of each dust control measure even greater.

Procurement Considerations for Dust-Control-Optimized Fiberglass Sheets and Solutions

Strategic choices about procurement have a big effect on how well dust control projects work. Knowing what a provider can do, what materials they need, and how they need to be shipped lets you find cost-effective options that help you reach your long-term business goals.

Buying Fiberglass Sheets: Pricing, Minimum Orders, and Bulk Supplier Selection

Strategies for buying in bulk can lower the cost of materials while keeping quality high across all production runs. When you buy in bulk, sellers can keep their standards smaller and the qualities of the material more uniform, which helps you predict how the machine will work and how much dust it will make. Different suppliers have very different minimum order amounts. For example, specialized composite makers usually need bigger pledges than general industrial suppliers. Pricing systems usually encourage buying in bulk, but procurement teams have to weigh the cost saves against the costs of keeping stockpiles and the length of time that materials will last. When choosing a supplier, you should look at their quality certification programs, expert help, and knowledge with uses that are sensitive to dust. Long-term ties with suppliers let you work together to create materials that are best for your machining and dust control needs.

Shipping and Delivery: Ensuring Product Quality Upon Arrival

The purity of the material is protected and contamination that could affect machine performance is avoided by properly packing and handling during transport. To keep edges from getting damaged and lamination from happening during shipping, good sellers use moisture barrier packing and protective padding. Coordinating delivery schedules makes sure that materials come when they're needed and cuts down on storage time that could cause damage from weather or handling. For some custom composites, temperature-controlled transport may be needed to keep the glue from breaking down, which could make cutting more dusty. When materials are received, they are inspected to make sure they are in good shape and to provide information for quality control programs that help make sure similar results are achieved in manufacturing.

Trusted Brands and Manufacturers Specializing in Fiberglass Sheets for Machining

Manufacturers that have been around for a while and have a history of making composite materials like the fiberglass sheet can be trusted more and offer better technical help for tough uses. Companies that only sell electrical insulation materials usually have tighter quality controls and more thorough testing programs than companies that sell a wide range of materials. Manufacturer certifications, like ISO quality control systems and approvals specific to the industry, give you even more peace of mind that the traits and performance of the material will stay the same. Technical support services, such as advice on how to machine things and help with fixing problems, add value beyond just supplying materials. Being close to a factory can cut down on shipping costs and delivery times while also making it easier to work together on unique needs and quality standards.

Maintenance and Operational Best Practices for Sustained Dust Control

Long-term success of dust control systems rests on regular upkeep and paying close attention to how they work. Preventive repair programs and the right training make sure that things keep working well and that accidents and unwanted breaks are kept to a minimum.

Routine Maintenance Tips for Fiberglass Sheet CNC Machining Equipment

Regularly checking and cleaning dust collection systems keeps them working at their best and increases the life of the equipment. Scheduling filter replacements based on measures of pressure drop instead of set times saves money and improves the efficiency of filtering. Inspection and repair programs for cutting tools stop the buildup of dust that happens over time as tools get dull. Lubricating the moving parts in dust extraction systems keeps them from wearing out too quickly and keeps the airflow steady. Calibration of airflow tracking tools gives correct information on how well the system is working and early warning of problems that are starting to happen. Recording maintenance tasks creates past records that help with efforts to make things better all the time and meet guarantee requirements.

Long-Term Durability and Insulation Performance Maintained Through Proper Care

The way fiberglass sheets are stored has a big effect on their features and how they behave when they are machined later. Keeping things in climate-controlled storage stops them from absorbing water, which can cause more dust to form and weaker electrical qualities. When you handle materials the right way, you can avoid damage to the edges and delamination, which can cause more dust during cutting processes. Inventory rotation methods make sure that older materials are used up before younger ones. This keeps the properties from breaking down over long periods of storage. Testing stored materials on a regular basis makes sure they are still meeting standards and finds any damage before it affects the quality of production. These practices keep the value of the material investment high and make sure that the manufacturing process always produces the same results throughout the material's existence.

Training and Safety Protocols for Workers Handling Fiberglass Sheets

Comprehensive training programs teach workers the right way to handle dust, what safety gear they need, and what to do in an emergency when they are exposed to dust. Regular safety meetings encourage the right way to do things and give people a chance to talk about problems and ideas for making things better. Personal safety equipment programs make sure that workers have the right eye, skin, and breathing protection based on their job needs and risk levels. Emergency reaction plans cover what to do if a dust control system fails and make it clear how to keep workers safe while repair is being done. Constant learning about health risks and safety procedures keeps people aware and helps them follow the rules set by the government and the company's safety policies.

Conclusion

Effective dust control when CNC cutting fiberglass sheets needs a thorough approach that includes choosing the right materials, using advanced extraction systems, and following consistent work procedures. Investing in the right dust control technology pays off in the form of safer workers, better products, and compliance with regulations. To be successful, you need to know how composite materials work and come up with ideas that work in your individual production setting. As the needs of industry change, dust control methods must also change to stay successful and help meet efficiency goals. Material providers, equipment makers, and end users all work together to make dust control technology and best practices better all the time.

FAQs

As far as dust goes, what makes working with fiberglass sheets different from working with other materials?

Fiberglass sheets make a mix of dust that includes rough glass fibers and smooth polymer particles. This means that they need special filter systems that can handle both types of particles well while keeping airflow consistent.

How often should the screens that collect dust be changed when working with fiberglass?

How often filters need to be replaced relies on how much dust is in the system and how it is set up, but watching the pressure drop gives the most exact reading of when they need to be replaced, which is usually every week to month in high-production settings.

Can effective dust control methods be added to CNC tools that are already in use?

Yes, upgrade dust collection systems can work with CNC machines that are already in use. However, systems that were designed to work with CNC machines and have built-in dust control usually work better and are easier to maintain.

Partner with J&Q for Superior Fiberglass Sheet Solutions

As a company with more than 20 years of experience making insulation materials and improved understanding of dust control, J&Q can meet all of your CNC cutting needs. Because we have a lot of experience in foreign trade and work with top makers, we can always get you high-quality fiberglass sheet materials that are best for cutting settings with little to no dust. Our combined transportation network offers a one-stop service from finding materials to delivering them. This makes the buying process easier for you while still meeting high quality standards. Email us at info@jhd-material.com to talk about your needs for a fiberglass sheet source and find out how our knowledge can help your manufacturing processes.

References

American Industrial Hygiene Association. "Guidance for Controlling Health Hazards in Fiberglass Manufacturing and Use." Journal of Occupational and Environmental Hygiene, 2019.

Composite Manufacturing Research Institute. "Best Practices for Dust Control in Composite Material Machining." Advanced Materials Processing, 2020.

National Institute for Occupational Safety and Health. "Criteria for Recommended Standard: Occupational Exposure to Synthetic Vitreous Fibers." Publication No. 2018-106, 2018.

Society of Manufacturing Engineers. "Machining Composite Materials: Dust Control and Worker Safety." Manufacturing Engineering Handbook, 2021.

International Association of Composite Manufacturers. "Guidelines for Safe Handling and Machining of Fiberglass Composites." Technical Report Series, 2019.

Occupational Safety and Health Administration. "Personal Protective Equipment Standards for Composite Material Processing." Federal Register Documentation, 2020.