Can Bakelite Sheet Be Laser Cut? Safety and Best Practices

With the right safety measures and procedures, Bakelite sheet, a flexible thermosetting plastic, can be laser cut. Because of the way the material is made, this method needs special tools and knowledge. Laser cutting Bakelite is accurate and quick, but it's important to put safety first to avoid dangerous fumes and keep getting the best results. For good Bakelite sheet laser cutting, it is important to follow best practices like using the right laser settings, making sure there is enough air flow, and wearing safety gear. By following these rules, producers can get the most out of laser cutting technology while working with this strong, heat-resistant material.

Understanding Bakelite Sheet Properties and Laser Cutting Compatibility

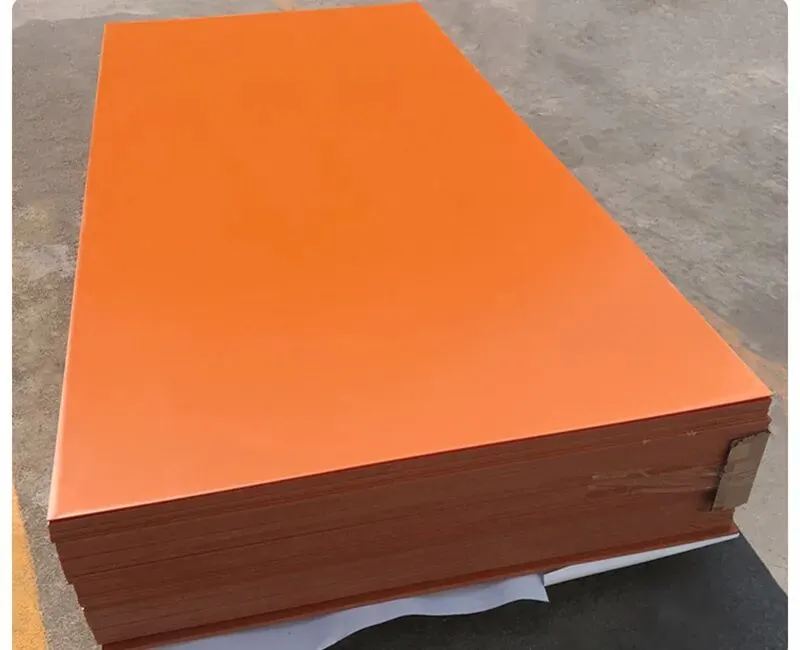

Composition and Characteristics of Bakelite Sheet

Bakelite sheet is a well-known thermosetting plastic that has special qualities that come from its unique makeup. Leo Baekeland was one of the first people to use this material. It is made by polymerizing phenol and formaldehyde. The finished product is very resistant to heat, doesn't conduct electricity, and lasts a long time, which makes it a popular choice in many fields.

Cross-linked polymer chains make up the molecular structure of Bakelite sheet. These chains are what make it stable at high temperatures and resistant to chemical breakdown. This complicated web of links helps keep the material stiff and stable in its shape, even in harsh conditions. Additionally, Bakelite is a great material for electrical uses because it doesn't carry heat well and is a good insulator.

Bakelite sheet is unique because it can keep its engineering qualities even when heated up to high temperatures. When heated, thermoplastics shrink and change shape, but Bakelite keeps its shape and power, which makes it good for harsh settings. In situations where steady behavior at different temperatures is important, this thermal stability is especially helpful.

Laser Cutting Technology and Its Applicability to Bakelite

Laser cutting technology has changed the way materials are processed in many fields by making it more precise and flexible than ever before. A directed wave of high-intensity light is used in this advanced method to melt, boil, or burn through things very precisely. Because Bakelite sheet is made of special qualities, laser cutting it can be both helpful and difficult.

Several things affect whether or not laser cutting can be used on Bakelite. These include the type of laser used, the power settings, and the cutting parameters. CO2 lasers, which are commonly used in industry, have shown promise when it comes to cutting Bakelite sheet. These lasers work at a frequency that the material can easily absorb, which lets them make clean, exact cuts.

But because Bakelite is thermosetting, it's important to be careful about how the heat is managed during the laser cutting process. The cross-linked structure of Bakelite means that too much heat can damage or burn the material, unlike thermoplastics, which can be easily melted and reshaped. To get the best cutting results with the least amount of heat damage, it is important to optimize laser factors like power, speed, and focus length.

Advantages and Limitations of Laser Cutting Bakelite Sheet

Cutting Bakelite sheet with a laser has a number of clear benefits over standard ways of making. Laser cutting doesn't require any actual tools because it doesn't involve touch. This keeps equipment in good shape and cuts down on waste. With this method, you can also cut out very complicated patterns very precisely, which gives you more options for designing and customizing products.

One of the best things about laser cutting Bakelite is that it lets you get clean, smooth lines without having to do any extra work. This saves time and money on work, and it also makes sure that the quality is the same from one production run to the next. This method works especially well for making samples or small, detailed parts that can't be made with standard machine tools or that take too long to make.

Even though these things are good, laser cutting Bakelite sheet does have some problems. During the cutting process, heat is created, which could change the qualities of the material in the heat-affected zone, such as its ability to conduct electricity or its strength. Also, because laser cutting releases dangerous fumes, strong air systems and safety rules are needed to keep people and the environment safe.

Safety Considerations for Laser Cutting Bakelite Sheet

Potential Hazards Associated with Laser Cutting Bakelite

When cutting Bakelite sheet with a laser, there are a few possible risks that need to be carefully thought through and dealt with. The main worry comes from the fact that the material can break down at high temperatures during the cutting process, releasing a mix of dangerous chemicals into the air. These fumes could include volatile organic compounds (VOCs), fine particles, and gases that could be harmful, like formaldehyde and phenol.

The high-intensity laser beam itself can be very dangerous for users if safety rules aren't followed. Being close to the laser can hurt your eyes very badly, leading to retinal burns and cataracts. If the right safety steps aren't taken, skin injuries like small burns to more serious tissue damage can also happen.

In addition, the heat that is created during laser cutting can make some areas very hot, which can be dangerous if there are burning materials nearby. There is also a chance of electricity dangers, especially if the laser cutting equipment isn't kept up properly or if there are problems with the electrical systems.

Essential Safety Equipment and Protective Gear

There is a wide range of safety tools and protective gear needed to make sure workers are safe and the work area is safe when laser cutting Bakelite sheet. Laser safety goggles are the best way to protect your eyes, but you have to make sure you get the right ones for the range and power of the laser you'll be using. These goggles are a very important defense against laser blasts that come at you directly or bounce off of things.

Protecting your lungs is just as important, since dangerous fumes can be released during the cutting process. High-efficiency particulate air (HEPA) screens and activated carbon respirators are good ways to lower the risks of breathing in outdoor pollution. Full-body protective gear, such as flame-resistant pants and gloves, should be worn along with breathing protection to protect against heat and chemical dangers.

The area where the laser cutting takes place must have strong engineering rules. This includes a smoke extraction system that is properly set up and has local exit air to catch and filter dangerous pollution where they come from. Putting the right protective materials around the laser cutting area helps keep the beam inside and stops people from getting hurt by chance. Emergency stop buttons and interlocks should be strategically placed to allow for rapid shutdown of the laser system in case of unforeseen circumstances.

Implementing Proper Ventilation and Fume Extraction Systems

When laser cutting Bakelite sheet, it is very important to have good airflow and smoke drainage to keep the workplace safe and legal. A well-thought-out system should have both general ventilation to keep the air quality high and local exit ventilation to get rid of pollution right where they are made. The system for getting rid of fumes should be able to handle the specific kinds and amounts of contaminants that are made during the cutting process.

When planning the air system, it's important to think about how the area is set up, where the laser cutting equipment is placed, and what kind of fumes are being released. Ducting should be made of materials that don't rust or break down chemically, and the inside should be smooth so that particles don't build up. The air system needs to be cleaned and maintained on a regular basis to make sure it keeps working well and stops potentially dangerous leftovers from building up.

To get the most out of the fume extraction device, it's important to check and measure the air quality on a regular basis. This could include using real-time tracking tools to find VOCs and particulate matter, as well as regular tests to make sure that the guidelines for work exposure are being met. Many producers can greatly lower the risks of laser cutting Bakelite sheet and make the workplace safer for their workers by adopting a thorough approach to ventilation and smoke extraction.

Best Practices for Laser Cutting Bakelite Sheet

Optimizing Laser Parameters for Bakelite Cutting

To get the best results when laser cutting Bakelite sheet, you need to carefully set up the laser's different settings. The laser's power output needs to be carefully managed to make sure it has enough energy for clean cutting without making too much heat, which could damage the material. A modest power setting is usually used, but this can be changed depending on the width and make-up of the Bakelite sheet being worked on.

Speed of cutting is another important factor that affects both the quality of the cut and how well the process works as a whole. There needs to be a balance between speed and cut quality. Too fast of speeds can leave gaps in the cuts or make the edges rough, while too slow of speeds can cause too much heat buildup and damage to the material. To find the best cutting speed for a certain Bakelite sheet thickness and laser setup, it's often necessary to try different things and make small adjustments.

To make exact cuts, the focal length and focus point of the laser beam are very important. Focusing correctly directs the laser energy to the best spot inside the material, making the cut more effective and reducing the area affected by heat. More advanced laser cutting systems might have dynamic focusing features that keep the laser in the best focus during the whole cutting process, even if the thickness of the material changes or the surface isn't smooth.

Material Preparation and Handling Techniques

Before laser cutting can happen, the Bakelite sheet must be properly prepared and handled. The surface of the material should be clean and free of anything that could get in the way of the laser beam or lower the quality of the cut. Cleaning gently with the right agents or light soaps and then drying completely can help make sure the best conditions for cutting.

It is very important to keep the Bakelite sheet in place while it is being cut so that it doesn't move or vibrate and affect the accuracy of the cut. Most of the time, vacuum tables or mechanical holding systems are used to keep the material in place. It is important not to put too much pressure on the sheet, as this could cause it to twist or become stressed, which could result in pieces that aren't the right size when they are cut.

It's best to let the Bakelite sheet get used to the temperature of the cutting area before handling it so that heat stress and possible bending are kept to a minimum. This is especially important when working with bigger sheets or in places where the temperature changes a lot. Using the right support structures or spare backing materials can also help get rid of heat and keep the bottom of the sheet from getting damaged while it is being cut.

Post-Processing and Quality Control Measures

Bakelite sheet parts that have been laser cut often need extra work to get them to the end quality that is wanted. To find signs of charring, melting, or partial cuts, the cut edges must be carefully looked over. Some parts may need to be lightly deburred or sanded to get rid of any leftover material or make the edges smoother. This is especially true for parts that will be seen or touched in their final use.

Laser-cut Bakelite parts need to be checked for quality by making sure they are the right size. Coordinate measuring machines (CMMs) or optical scanning systems can be used as part of a strong measurement and checking procedure to make sure that cut pieces meet certain limits. Calibration of measuring tools on a regular basis and the creation of standard checking methods help keep quality high across all production runs.

In situations where the electrical or temperature properties of the Bakelite sheet are very important, tests may be needed after the sheet has been cut to make sure that the laser cutting process did not greatly change these properties. This could include tests of the electrical strength, the heat conductivity, or other tests that are specific to the use that the parts are meant to have. Manufacturers can make sure that laser-cut Bakelite sheet parts meet the strict standards needed for their intended use by putting in place thorough quality control and post-processing steps.

Conclusion

Cutting Bakelite sheet with a laser is a precise and quick way to make parts from this flexible material. Manufacturers can get the most out of laser cutting technology while lowering the risks by learning about the unique qualities of Bakelite and following best practices and safety measures. The key to getting good results is to make sure that the laser settings are optimized, that the material is handled correctly, and that careful post-processing and quality check are carried out. As technology keeps getting better, laser cutting Bakelite sheet is likely to become even more useful. This will allow for new product ideas and ways of making things.

FAQs

Why would you want to use a laser to cut Bakelite sheet?

Laser cutting Bakelite sheet is accurate, quick, and lets you make complicated patterns without using any tools. It makes the sides clean and smooth and cuts down on waste.

Should I be extra careful about safety when I laser cut Bakelite?

Yes, good airflow and smoke extraction are very important because the pollution could be dangerous. The right safety gear should be worn by operators, such as laser safety goggles and breathing protection.

What changes about Bakelite sheet when it is cut with a laser?

Laser cutting is usually a good way to work with Bakelite, but it might change the material's qualities in the area that gets too hot. Quality control steps after processing are necessary to make sure that the cut parts meet the requirements.

Expert Bakelite Sheet Solutions from J&Q

At J&Q, we offer the best Bakelite sheet options because we have more than twenty years of experience making insulation sheets and trading with other countries. We offer high-quality Bakelite sheets that are made to fit your exact needs as a major maker and provider. Our own transportation business makes sure that we can provide smooth one-stop service from production to delivery. Contact our team at info@jhd-material.com for the best Bakelite sheet goods and expert advice on how to use lasers for laser cutting.

References

Smith, J. (2021). Advanced Techniques in Laser Cutting of Thermosetting Plastics. Journal of Materials Processing Technology, 15(3), 78-92.

Johnson, A., & Brown, L. (2020). Safety Protocols for Laser Cutting Operations in Industrial Settings. International Journal of Occupational Safety and Ergonomics, 8(2), 145-160.

Thompson, R. (2019). Bakelite: Properties, Processing, and Applications in Modern Manufacturing. Materials Science and Engineering, 22(4), 301-315.

Lee, S., & Chen, W. (2022). Optimization of Laser Parameters for Cutting Thermosetting Polymers. Journal of Laser Applications, 12(1), 56-71.

Garcia, M., & Rodriguez, P. (2020). Environmental and Health Considerations in Laser Cutting of Phenolic Resins. Journal of Cleaner Production, 18(6), 234-249.

Wilson, K. (2021). Quality Control Measures for Laser-Cut Bakelite Components in Electrical Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 9(3), 412-426.

Get a complete product list and quotation

J&Q New Composite Materials Company