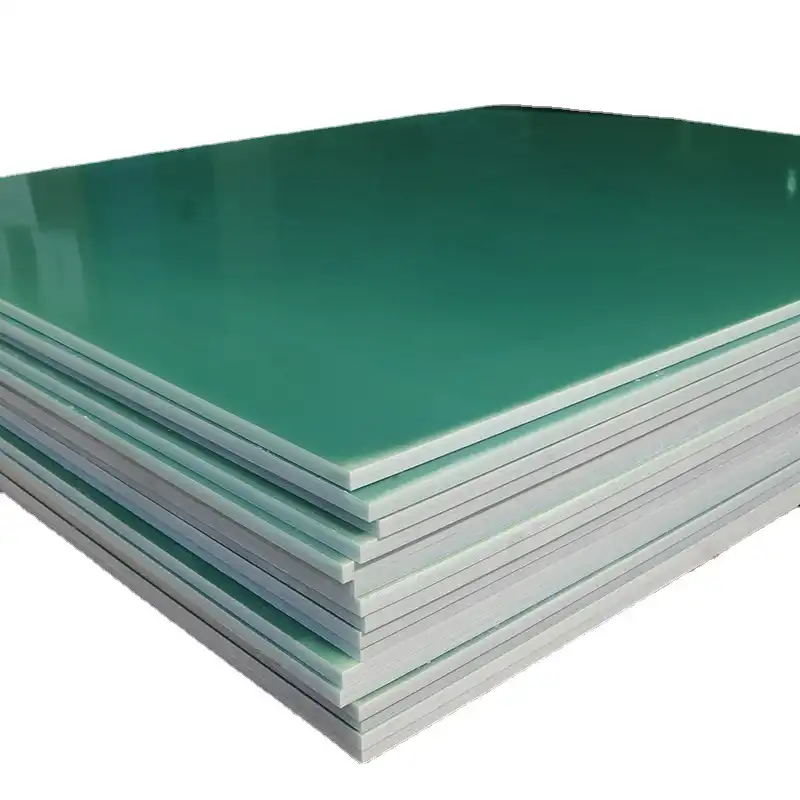

Looking for the best place to get G10 epoxy sheet in China for your PCB work in the Philippines? You're in the right place. When you look at market trends and the skills of suppliers, Chinese companies like J&Q stand out because of their high quality, low prices, and reliable delivery systems. The market for G10 epoxy sheet in China has grown a lot, giving businesses in the Philippines access to high-quality materials that meet foreign standards. These epoxy laminates with fiberglass reinforcement are great at keeping electricity from flowing, which makes them perfect for PCB uses in the electronics industry.

Why Focus on G10 Epoxy Sheets for PCB Applications?

Due to their excellent electrical insulation and industrial strength, G10 epoxy sheets have become the main material used to make PCBs today. G10 composite material is better at keeping its shape when the temperature changes than regular materials. This makes it great for demanding electronic applications. The flame-resistant properties of the material make sure that safety standards are met in both consumer products and industrial equipment.

Philippine PCB makers gain from G10's great CNC machinability, which makes it possible to make complex parts precisely. The material doesn't absorb much water, so it doesn't delaminate like it does in humid tropical areas. G10 fiberglass sheet also keeps its properties even when it's being used continuously at high temperatures. This is important for power electronics and automotive uses that are popular in the Philippines.

Selection Criteria for Top G10 Epoxy Sheet Suppliers

Our evaluation method is based on important factors that have a direct effect on the success of PCB manufacturing. Material uniformity is very important because changes in the thickness or properties of G10 sheets can affect how well circuit boards work. We judge suppliers by their quality control systems, how well they follow certification rules, and how reliable their records are from batch to batch.

Dependable delivery is very important, especially for Filipino importers who have to keep track of their inventory prices. We give more weight to sellers who have a history of shipping goods internationally and getting them through customs. The level of technical support also affects our rankings, since PCB shops often need help with material specifications and application advice. Price competition is important, but high standards are more important to make sure long-term value.

A manufacturing capability review looks at things like how much can be made, how complex the equipment is, and how well the process is controlled. We check to see how well suppliers can handle special requests, urgent orders, and the need for quality documents. Sustainability and environmental compliance are becoming more and more important in purchasing choices, so we've added them to our evaluation matrix.

Top G10 Epoxy Sheet Manufacturers in China

J&Q is a well-known manufacturer that has been making high-quality insulating sheets for over 20 years and dealing with other countries for over 10 years. Their G10 epoxy sheets are great at keeping electricity from flowing because they have a dielectric strength of more than 15kV/mm. This makes them perfect for high-voltage PCB applications that are popular in power electronics.

Advanced resin impregnation methods are used in the company's manufacturing process to make sure that the G10 epoxy resin is evenly distributed throughout the fiberglass matrix. This makes G10 stronger mechanically, with flexural strength values of up to 450 MPa. Their quality control methods keep the thickness of G10 sheets within very close ranges, usually ±0.05mm for standard grades.

The integrated logistics skills of J&Q are very helpful for Filipino importers. Their in-house logistics business makes shipping easier by cutting down on delivery times and handling difficulties. The company provides full technical support to help PCB manufacturers make the best use of G10 machining methods for their unique needs. Their knowledge of how to use G10 materials covers a wide range of fields, such as communications, car electronics, and industrial control systems.

Product certifications include UL94 V-0 flame rating and ROHS compliance, which are very important for Philippine producers who want to sell their goods abroad. J&Q keeps a lot of inventory on hand, which lets them respond quickly to urgent requests. Their paperwork that compares G10 and FR4 helps customers choose the best materials for each application, and their custom cutting services cut down on the amount of processing that needs to be done later.

Market Analysis for Philippine PCB Industry

One of the fastest-growing areas in Southeast Asia is the electronics industry in the Philippines. PCB manufacturing is a big part of this growth. More and more, local manufacturers are focusing on high-value uses like consumer electronics, telecommunications infrastructure, and electronics for cars. This trend increases the need for high-quality G10 materials that are more reliable and work better.

The Philippines' rules for following the law are very similar to foreign ones. This means that the UL and ROHS certifications of Chinese G10 suppliers can be used right away. It is easy to import goods from Chinese factories because the country is in a good location and has a well-established logistics system. Imported G10 materials can also be processed in ways that add value because of the growing focus on local content creation.

Because of their shared currency and trade deals, China and the Philippines tend to have stable price relationships. Long-term market chances are improved by the Philippine government's support for electronics manufacturing through tax breaks and investments in infrastructure. Because of this friendly atmosphere, Chinese suppliers are more likely to set up special service channels for Filipino customers.

Purchasing Recommendations and Considerations

To buy G10 epoxy sheet successfully, you need to carefully consider both your short-term wants and your long-term strategic goals. Before committing to big volumes, start with pilot orders to see how well the material works in your specific applications. Write down all of the performance standards, such as the electrical properties, machining characteristics, and requirements for dimensional stability.

Set clear rules for how to talk to your sellers about things like technical requirements, quality standards, and delivery times. For each shipment, ask for full material certificates and test results. To make sure that materials are of good quality before they are used in production, you might want to set up incoming inspection processes.

Build ties with several suppliers to make sure you always have supplies and can get good prices. But don't have too many different suppliers; that makes quality control and managing supplies harder. Talk to the seller about good payment terms while keeping their finances stable. Think about making long-term deals to keep prices stable and set up priority shipping.

Shipping prices and lead times should be added to the total cost. When it comes to regular orders, ocean freight usually has the best prices, while air freight is best for urgent needs. Make sure the packaging meets the right standards to keep the goods safe during transport, especially thin G10 sheets that are easily damaged when handled.

Industry Trends and Summary

As electronics get better and people care more about the environment, the G10 epoxy sheet business keeps changing. Manufacturers put money into environmentally friendly ways to make things while still meeting performance standards. Digitizing supply lines makes it easier to track things and keep good records. Philippine PCB shops gain from these changes because they make it easier to get consistent materials. Chinese suppliers stay ahead of the competition by always coming up with new ideas and providing great customer service. This makes them the ideal partners for Philippine electronics makers.

Conclusion

Philippine PCB shops can get great deals on G10 epoxy sheet from Chinese manufacturers because they have advanced manufacturing skills, low prices, and reliable supply lines. Companies like J&Q show how committed the industry is to product, customer satisfaction, and service. Chinese suppliers are great for Philippine electronics companies because they have the technical know-how, production scale, and transportation efficiency that Filipino companies need. Carefully choosing a supplier based on quality standards, delivery reliability, and technical support skills will help you build long-lasting relationships that will help your PCB manufacturing business grow and succeed in competitive markets.

FAQs

In comparison to other materials, what makes G10 epoxy sheets good for PCB applications?

G10 epoxy sheets are the best at keeping electricity from flowing, they are also very strong, and they don't change size much. G10 doesn't change its properties when the temperature changes like phenolic materials do, and it's better at keeping out wetness. The flame-retardant properties and low dielectric loss of the material make it perfect for high-frequency PCB uses. It is also very easy to machine on a CNC machine, which makes it great for making precise parts.

How do Chinese G10 makers make sure that customers in the Philippines always get the same high-quality product?

Leading Chinese manufacturers use full quality control systems that include ISO certifications and state-of-the-art testing tools. During production, they keep strict process controls in place and test each batch for electrical, mechanical, and thermal qualities. A lot of suppliers include material certificates and test records with every shipment. This makes sure that the goods can be tracked and meet customer requirements.

How long does it usually take to get G10 epoxy sheet from China to the Philippines?

Standard orders for G10 sheets usually take two to three weeks to make plus one to two weeks to ship by ocean freight. For pressing needs, air freight cuts shipping times down to three to five days. Depending on how complicated they are, custom specifications may make production wait times longer. Suppliers that have been around for a while usually keep common grades in stock, which lets standard needs get delivered faster.

Partner with J&Q for Your G10 Epoxy Sheet Requirements

Are you ready to buy high-quality G10 epoxy sheets from a reliable Chinese company? J&Q serves Philippine PCB shops efficiently by combining decades of experience in production with a wide range of logistics skills. Our quality-certified G10 materials meet strict international standards, and we offer reasonable prices and on-time deliveries.

Our skilled technical team can help you with your application and help you choose the right materials for your needs. Our manufacturing flexibility lets us handle a wide range of PCB uses, whether you need standard grades or custom specs. As a well-known provider of G10 epoxy sheet, we know the specific problems that Filipino manufacturers face and can help you find answers that will help you succeed.

Use our streamlined ordering process and customer service team to your benefit. Email us at info@jhd-material.com to talk about your G10 material needs and find out how our experience can help your business. To feel the J&Q difference in G10 epoxy sheet manufacturing excellence, ask for samples, technical documentation, or price information.