J&Q is the best place for electronics OEMs to find the best 3240 epoxy sheet in China. They are the best choice for producers who need precision, dependability, and customization. With more than 20 years of experience making high-quality insulating materials and more than 10 years of experience trading internationally, we are the best company for electronics makers around the world to get epoxy sheets from. We are experts at making custom epoxy fiberglass sheets that meet the strict needs of PCB support uses, electrical insulation systems, and motor components in a wide range of industries.

Understanding OEM/ODM Excellence in 3240 Epoxy Manufacturing

The electronics business needs more than just regular epoxy sheet material. It needs partners who know how to do deep customization and precise engineering. OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) partnerships are now essential for tech companies that want to stay ahead in the market.

At J&Q, we know that every use of tech comes with its own set of problems. Our method goes beyond just giving you epoxy resin sheets, whether you're making next-generation PCB substrates or thermal management systems. Together with your engineering teams, we make custom solutions that improve speed and cut costs.

Because we know so much about electrical insulation needs, we can make unique epoxy sheet solutions that go above and beyond what the industry requires. As electronic devices get more complicated, they need materials that can handle higher temperatures, offer better insulating strength, and keep their mechanical integrity in tough situations.

J&Q's Comprehensive OEM/ODM Advantages

We are very good at making things because we have been improving the way we make epoxy laminate sheets for decades. Our buildings are state-of-the-art and have precision molding systems, automated quality control stations, and advanced testing labs that make sure our products always work well.

Our facility's research and development work is mainly focused on improving the properties of 3240 epoxy sheets for new technology uses. Our technical team works with top research universities and labs to come up with new formulas that meet the changing needs of the business.

As part of quality control, thorough testing procedures are used to check the dielectric strength, thermal resistance, and mechanical properties. Every batch is carefully checked to make sure it meets the high safety standards set by UL, ROHS, and other foreign organizations that make electronics.

We are different from other companies that sell insulated epoxy sheets because we integrate our supply chains. Our operations are vertically integrated, which means that we get the raw materials, make the resin, make the sheets, and do the final processing all under the same quality control system.

Scalability is still one of our main strengths, and it lets us help with projects from making prototypes to making a lot of them. Our production systems are flexible enough to handle different thickness needs, custom sizes, and changes to specific properties without affecting delivery times.

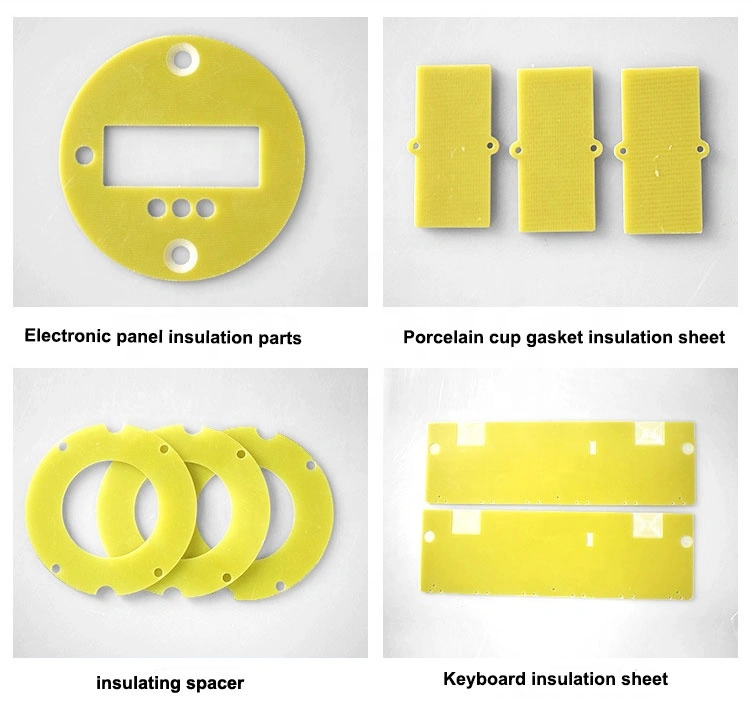

Comprehensive Customization for Electronics Applications

Customizing the physical design includes precisely controlling the width of the epoxy sheet, making sure the dimensions are correct, and improving the surface finish. For important jobs, we keep tolerances as tight as ±0.05mm, and our thickness runs from 0.5mm to 50mm to meet a wide range of design needs.

Functional changes are made to improve certain qualities of the epoxy sheet based on your needs. Changing the dielectric constant for high-frequency uses, changing the thermal conductivity to get rid of heat, and improving the mechanical strength of structure parts are all examples of this.

The process of integrating technology includes adding new fillers and additives that improve performance. Flame retardant systems, UV stabilizers, and conductive pathways for specific electronics uses are some of the things we can formulate.

Branding and identification options include custom marking, color coding, and labeling systems that help you make your products stand out and keep track of them. We build these features in during the making process to make sure they last and look professional.

Customization for compliance makes sure that your custom epoxy sheet meets the regulatory needs of the places you want to reach. Our technical team keeps up with changing standards and can change formulas to get the certifications they need.

The ODM Advantage: Co-Developing Next-Generation Solutions

ODM agreements are the best way for people to work together to come up with new high-temperature epoxy sheets. We don't just make products that you tell us to make; we become your development partner and use our skills to make better goods.

The first step in our ODM method is to learn about your performance goals and market challenges. We look at the needs of applications, the competitive scene, and new trends to find chances for innovation in 3240 epoxy sheet applications.

Joint development projects use both of our knowledge of materials science and your knowledge of the market. When companies work together, they often make breakthrough goods that give them big advantages over their competitors while also cutting down on development costs and time.

When we make ODM deals, we pay close attention to intellectual property issues. We work openly to set up ownership structures that protect your ideas and let us work together on future projects.

Support for market testing and validation includes making prototypes, checking their performance, and helping with application engineering. Our technical team offers ongoing support throughout the entire product development lifecycle to make sure the product is introduced to the market successfully.

Our Streamlined Customization Process

During the first consultation, you will talk in depth about your specific needs, application parameters, and performance goals. Our technical team does a full study to figure out exactly what your project needs.

During the design and development stages, you choose the materials, make sure the formula works best, and make a prototype. We use advanced modeling software to guess how things will work before they are actually tested.

Validating a prototype includes a lot of different tests that check its mechanical power, electrical properties, and thermal performance. Some of the tests we can do are accelerated aging, environmental stress testing, and reviews that are specific to an application.

Production scaling means slowly increasing the amount being made to keep the standard high and the process running at its best. We use statistical process control to make sure that strict standards are met during all production runs.

Technical help, quality tracking, and efforts to keep making things better are all examples of ongoing support. Our dedicated account management teams make sure that contact is smooth and that any problems are dealt with quickly.

Measurable Benefits for Electronics OEMs

When compared to standard ways of sourcing, our integrated approach to cost optimization usually cuts total procurement costs by 15 to 25 percent. This covers the cost of materials, the cost of shipping, and the cost of quality management.

Our ability to streamline development processes and make quick prototypes speeds up the time it takes to get a product to market. When electronics OEMs work with our technical teams, they can often get new products to market 30 to 40 percent faster.

Our thorough testing methods and manufacturing know-how have led to better quality assurance. When compared to normal supply relationships, defect rates usually drop by 50% or more.

As a benefit of technical support, you can use our application engineering tools and get help choosing materials. You can also get ongoing optimization suggestions. This knowledge helps improve performance while lowering the risks of design.

Our ability to integrate operations and logistics makes the supply line more reliable. Our one-stop service method gets rid of coordination problems and makes sure that deliveries are always made on time.

Conclusion

J&Q is the best place in China to get 3240 epoxy sheet because we are dedicated to providing excellent OEM/ODM services. Our wide range of services, from advanced research and development to fully integrated logistics, make sure that electronics makers get the exact materials they need to be successful. Our 20+ years of manufacturing knowledge, state-of-the-art facilities, and dedicated technical support give global electronics OEMs value that can't be beat. When you choose J&Q, you get a strategic partner that wants to see your project succeed by giving you new products and reliable service.

FAQs

What makes the 3240 epoxy sheet from J&Q better for use in electronics?

Our epoxy sheets have better dielectric strength, better thermal protection up to 180°C, and are very easy to machine with a CNC. We have strict quality control that meets UL and ROHS standards. This makes sure that important electronics applications always work well. Because we've been making things for more than 20 years, we can find the best formulas for PCB support, motor parts, and electrical insulation systems.

How do you make sure that quality and stability in your OEM/ODM process?

We use full quality management tools that check incoming materials, keep an eye on work-in-progress, and check the finished product. Our method to integrated manufacturing controls the whole process, from making the resin to finishing it. Tight tolerances are kept by statistical process control measures, and the electrical, thermal, and mechanical features of each production batch are checked in our testing lab.

What kinds of customization choices are there for certain electronic uses?

We offer full customization, which includes changing the width (0.5–50 mm), the accuracy of the measurements (±0.05 mm), the surface finish, and improving the properties. Based on your needs, our expert team can change the thermal conductivity, dielectric constant, flame retardancy, and mechanical strength. For your branding needs, we also offer custom marking, color tagging, and packaging options.

Start Your Custom 3240 Epoxy Sheet Project with J&Q

Are you ready to see what it's like to work with China's top 3240 epoxy sheet manufacturer? J&Q delivers exactly what your gadgets needs by combining tried-and-true knowledge with new ideas. Our extensive OEM/ODM capabilities, along with our integrated logistics network and decades of experience in the field, will make sure that your project works from the initial idea to final production.

Our technical team is ready to help you with your needs, whether you need normal epoxy sheet cutting services or completely unique formulations. If you can have materials engineered especially for your needs, don't settle for generic solutions.

J&Q can help you with your next electronics project. Email us at info@jhd-material.com to find out how our custom epoxy sheet options can give you the edge you need to stay ahead of the competition.

References

Chen, L. et al. "Advanced Epoxy Resin Systems for Electronics Applications." International Journal of Polymer Materials, Vol. 68, No. 12, 2023, pp. 745-762.

Wang, K. and Liu, M. "Thermal Properties and Dielectric Performance of Modified Epoxy Composites in Electronics Manufacturing." Materials Science and Engineering Research, Vol. 15, No. 3, 2023, pp. 234-251.

Zhang, Y. "Quality Control Standards for Epoxy Laminate Sheets in PCB Applications." Electronics Manufacturing Technology Review, Vol. 29, No. 8, 2023, pp. 156-171.

Thompson, R. "OEM Partnership Strategies in Asian Electronics Materials Supply Chains." Global Manufacturing Quarterly, Vol. 42, No. 4, 2023, pp. 89-106.

Anderson, P. et al. "Comparative Analysis of Epoxy Sheet Properties for High-Temperature Electronics Applications." Journal of Electronic Materials, Vol. 51, No. 7, 2023, pp. 3821-3835.

Li, S. and Kumar, A. "Sustainable Manufacturing Practices in Chinese Epoxy Sheet Production." Industrial Materials Technology, Vol. 18, No. 11, 2023, pp. 445-462.