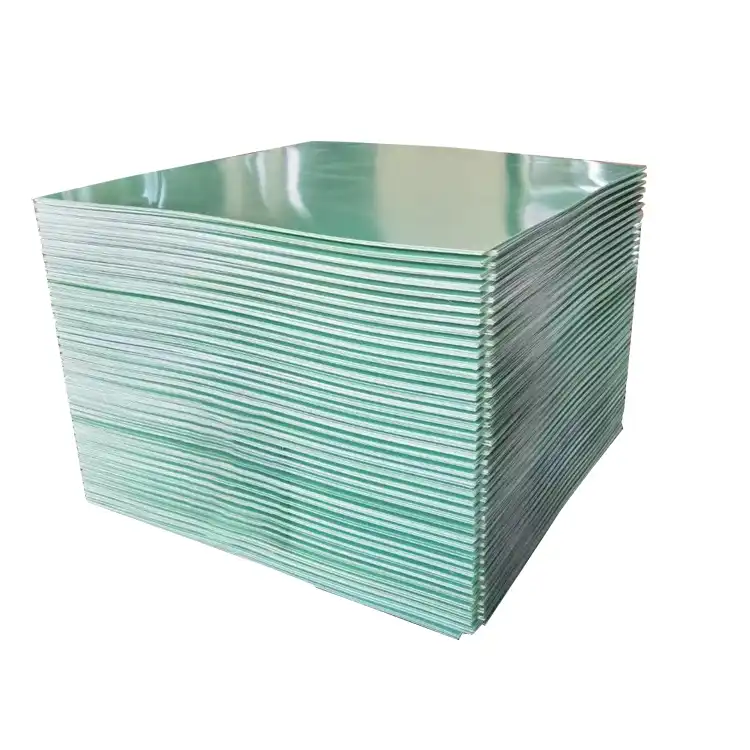

UK PCB manufacturers regularly look to Chinese suppliers for superior FR4 epoxy sheet solutions when seeking premium printed circuit board materials. J&Q is the top supplier after analyzing several manufacturers in China's industrial environment. They produce outstanding flame retardant laminates that adhere to strict UL and ROHS regulations. For demanding electronic applications, their extensive selection of glass fiber reinforced epoxy substrates provides unparalleled temperature resistance and dielectric strength.

Why UK PCB Manufacturers Choose Chinese FR4 Epoxy Suppliers?

Strong economic and technological benefits are seen in the global trend toward electrical insulating materials made in China. Laminate sheets with constant mechanical qualities and exact thickness tolerances are produced by China's sophisticated manufacturing infrastructure. Cost-effective solutions are advantageous to UK electronics companies without sacrificing quality standards.

Chinese producers such as J&Q take advantage of decades of expertise in glass fiber reinforcing methods and epoxy resin production. Superior PCB substrates with outstanding electrical insulating qualities that can tolerate harsh working conditions are the result of this expertise. Batch-to-batch consistency, which is essential for high-volume PCB fabrication, is ensured by the integration of automated production lines.

Essential Selection Criteria for Premium FR4 Materials

Suppliers of FR4 epoxy sheets must be thoroughly evaluated using a variety of performance metrics. Dielectric strength is still crucial; high-quality materials have breakdown voltages of more than 20 kV/mm. Continuous operation at temperatures as high as 130°C must be supported by thermal resistance characteristics without compromising mechanical strength.

A key component of long-term dependability is moisture resistance. Even in situations with high humidity, premium copper-clad laminates retain their dimensional stability. Processing efficiency is determined by CNC machinability; clean drilling and routing without delamination are made possible by superior materials. Regulatory acceptance in global markets is guaranteed by compliance certificates such as UL recognition and ROHS compliance.

PCB manufacturing yield rates are impacted by consistency in thickness across big panel dimensions. Top providers keep thickness tolerances across typical board specifications within ±0.05mm. During lamination procedures, the quality of the surface finish affects copper foil bonding strength and solder mask adhesion.

Top-Rated J&Q FR4 Epoxy Sheet Solutions

Premium Grade FR4-TG170 High-Temperature Laminate

The flagship TG170 series from J&Q offers outstanding thermal performance for demanding power electronics and automotive applications. Up to the glass transition point of 170°C, this sophisticated glass fiber reinforced substrate retains its mechanical integrity at high temperatures. During several temperature cycling cycles, the unique epoxy resin formulation offers exceptional dimensional stability.

Important technical requirements include flexural strength greater than 450 MPa and breakdown voltage greater than 25 kV/mm perpendicular to laminations. In humid conditions, the low moisture absorption rate of 0.08% guarantees constant electrical characteristics. The tolerance parameters for the available thicknesses, which vary from 0.4mm to 6.0mm, satisfy IPC-4101 Class B requirements.

Excellent CNC machining properties that allow for precise component mounting holes without microcracking are among the manufacturing advantages. Smooth drilling operations at high spindle speeds are made possible by the homogeneous distribution of glass fibers. Throughout product lifecycles, dependable circuit trace adherence is ensured by copper foil peel strength exceeding 1.4N/mm.

For switching power supplies, LED driver circuits, and automotive control modules that need to operate at higher temperatures, this high-end laminate FR4 epoxy sheet version is perfect. The improved flame retardant qualities satisfy V-0 rating requirements while keeping the halogen level low for environmental compliance.

Standard Grade FR4-TG130 Universal PCB Substrate

J&Q's most adaptable printed circuit board material, the TG130 series, strikes a balance between cost-effectiveness and performance attributes for the production of common electronics. In a variety of industrial applications, such as consumer electronics and telecommunications equipment, this tried-and-true glass fiber epoxy composite provides dependable electrical insulation.

Electrical characteristics include a dissipation factor of less than 0.02 and a dielectric constant of 4.5 at 1MHz. Circuits with a moderate power density can dissipate heat effectively thanks to the thermal conductivity of 0.3W/mK. Mechanical strength requirements include impact resistance appropriate for portable device applications and flexural modulus more than 18GPa.

Consistent drilling performance across different board thicknesses without the need for specific tooling changes is one of the processing advantages. Excellent compatibility with popular solder mask systems and surface finish techniques is provided by the standard epoxy resin chemistry. Across common panel sizes, dimensional stability keeps flatness standards under a 0.5% variation.

With dependable interlayer adhesion, this adaptable material for circuit fabrication may support multilayer structures up to 20 layers. In high-frequency digital circuitry, signal skew is reduced by the balanced glass weaving pattern. Chemical resistance qualities allow them to resist common chemicals used in PCB production, such as acidic cleaning agents and alkaline etchants.

Heavy Copper FR4-HC Series for Power Applications

Power electronics that need improved current carrying capacity and thermal control are accommodated by J&Q's specialty heavy copper laminate. This sturdy PCB substrate provides superior electrical insulation between high-voltage circuits while supporting copper weights ranging from 4 to 10 ounces.

Increased flexural strength and enhanced thermal shock resistance are two examples of improved mechanical qualities that are crucial for power module applications. During temperature cycling, the improved epoxy resin system can tolerate the thermal expansion pressures brought on by thick copper conductors. Even with thinner insulation, dielectric breakdown performance surpasses industry standards.

Specialized pressing cycles designed for heavy copper constructions and a controlled coefficient of thermal expansion that matches the properties of copper foil are two manufacturing issues. Under conditions of severe mechanical stress loading, delamination is prevented by the reinforced glass fiber architecture.

Applications include industrial welding equipment, motor drive controllers, and renewable energy converters, where significant thermal loads are produced by high current densities. The improved flame resistance satisfies strict safety requirements for installations of power distribution equipment.

UK Market Characteristics and Regulatory Requirements

Strict quality requirements for FR4 epoxy sheet reflecting safety-critical applications in aerospace, medical devices, and industrial automation are demanded by the UK electronics manufacturing business. Direct trade agreements with Chinese suppliers for FR4 epoxy sheet have become simpler as a result of Brexit, as prior EU regulatory complications have been eliminated.

The market acceptance of high-quality insulation materials is ensured by the UKCA marking criteria, which closely match current CE standards. Given the time-sensitive nature of electronics development cycles, UK manufacturers place a premium on suppliers' responsiveness and technical support capabilities.

Long-term cooperation partnerships are valued more in cultures than just transactional sourcing agreements. In-depth technical documentation and prompt communication about product details and delivery dates are valued by UK consumers. The engineering-focused procurement culture is shown in the preference for thorough testing certificates and quality system audits.

Smart Purchasing Strategies and Implementation Guidelines

Thorough supplier certification procedures, such as facility audits and quality system evaluations, are the first step in the successful procurement of FR4 materials. Thermal cycling experiments, moisture absorption investigations, and mechanical stress assessments under real-world application settings should all be included in sample evaluation programs.

Volume forecasting guarantees sufficient inventory levels for production continuity while enabling favorable pricing structures. Building partnerships with backup suppliers makes the supply chain resilient to unforeseen outages or periods of high demand.

Opportunities for technical cooperation include specialized glass weave patterns, customized resin compositions suited to particular application needs, and unique thickness specifications. Material selection and processing parameters are optimized when suppliers are involved early in the product development process.

Acceptance criteria, inspection methods, and corrective action procedures should all be outlined in quality agreements. Frequent performance evaluations uphold supplier accountability and encourage ongoing efforts to improve various performance indicators.

Industry Trends and Market Evolution

Higher frequency applications that call for sophisticated dielectric materials with enhanced signal integrity properties are being used by the electronics sector. Trends in miniaturization necessitate thinner substrates while preserving thermal performance and mechanical durability. The development of halogen-free flame retardant systems is driven by environmental requirements without sacrificing safety standards. Chinese producers increase manufacturing capacity and consistency for international PCB material supply chains by making significant investments in automation and quality control systems.

Conclusion

Carefully assessing technical prowess, quality control methods, and service responsiveness is necessary when choosing the best provider of FR4 epoxy sheets. J&Q is the go-to option for UK PCB manufacturers looking for dependable, high-performance electrical insulating solutions due to their extensive product line and superior production. Their dedication to client satisfaction and ongoing development guarantees the success of long-term partnerships across a variety of electronic applications.

J&Q is the perfect partner for your PCB substrate needs because of its cutting-edge materials technology, affordable prices, and attentive customer support. Purchasing high-quality materials from reputable vendors like J&Q eventually improves manufacturing efficiency and product dependability.

FAQs

Which certifications must to be offered by reputable FR4 suppliers?

Reputable manufacturers offer IPC-4101 specification compliance, ISO 9001 quality management certification, ROHS compliance certificates, and UL recognition. For complete regulatory compliance, additional certifications could include conflict minerals declarations and REACH registration.

How can the thermal performance of FR4 materials be confirmed?

Request test results for glass transition temperature, coefficient of thermal expansion, and decomposition temperature information from thermomechanical analysis (TMA). Results from differential scanning calorimetry (DSC) offer more information about thermal behavior for applications that depend on temperature.

What tolerances for thickness can I anticipate from high-end suppliers?

Good manufacturers keep thickness tolerances within ±0.03mm for precision applications and ±0.05mm for general grades. For best processing results, thickness uniformity across panel dimensions should stay within ±0.02mm.

Partner with J&Q for Premium FR4 Epoxy Sheet Solutions

For UK PCB producers, J&Q combines more than 20 years of experience in the production of insulation materials with extensive worldwide supply capabilities. Our state-of-the-art production facilities provide low pricing for volume requirements while upholding strict quality standards. Your production planning goals will be supported by dependable delivery schedules guaranteed by the integrated logistics network.

For the best material selection and processing settings, our technical staff offers application-specific advice. From small prototypes to large production runs, J&Q consistently provides high-quality, timely service. As a reliable provider of FR4 epoxy sheets, we are aware of how crucial material dependability is to your electronic devices.

Are you prepared to improve your approach to procuring PCB substrates? Get in touch with our knowledgeable staff to go over your particular needs and learn how J&Q's superior laminate solutions may improve your production processes. Get in touch with us right now at info@jhd-material.com to start working with a reputable leader in the field.