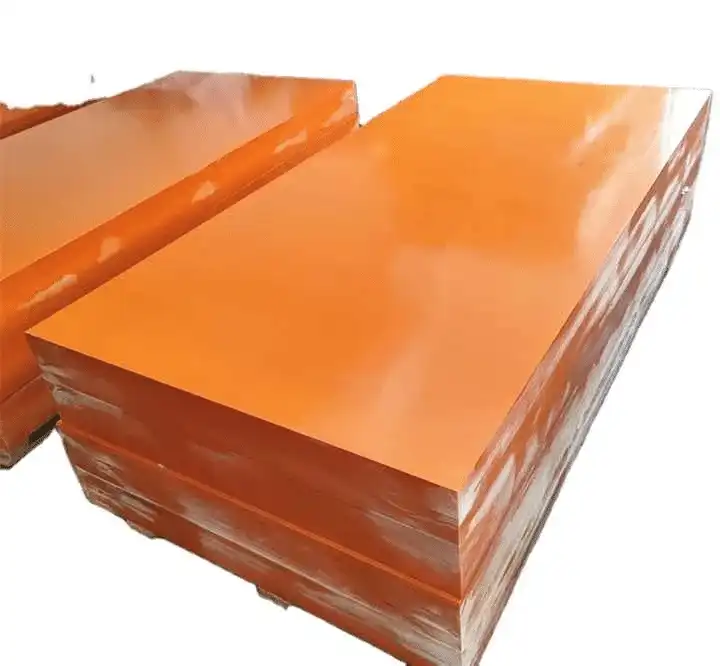

China makes some of the best Bakelite sheet materials for use in electrical panels. They do this by using advanced manufacturing methods and offering low prices. Leading Chinese makers have perfected phenolic resin mixtures that offer excellent electrical insulation, resistance to heat, and mechanical durability. These high-quality thermosetting plastic sheets are compliant with international standards such as UL and ROHS. This makes them perfect for use as support for PCBs, switches, and motor parts. Electrical makers all over the world rely on Chinese suppliers for their most important projects because they offer a wide range of customization options, precise machining, and reliable supply chain management.

Why Focus on Chinese Bakelite Sheet Manufacturing Excellence?

In the last twenty years, Chinese manufacturing has grown a lot, especially in the electrical insulating business. China's production of Bakelite sheets uses both advanced technology and trained craftsmanship to make goods that are on par with those made by traditional European companies but much cheaper. A lot of money has been spent by Chinese companies on high-tech molding tools, quality control systems, and technical know-how.

China's synthetic polymer business benefits from easy access to a wide range of raw materials and streamlined production methods. This lets companies keep quality high while increasing production to meet demand around the world. More and more, engineering managers and procurement teams see Chinese providers as dependable partners for their electrical panel needs.

Essential Selection Criteria for Premium Electrical Panel Materials

To choose the right laminate material, you need to carefully look at a number of technical factors. The most important thing to think about is the dielectric strength, which makes sure that the electrical protection works well even when the voltage changes. Long-term success in harsh environments where temperatures may be higher than normal is based on how well something resists heat.

The material's mechanical strength qualities have a direct effect on its ability to handle physical stress during use and installation. Chemical resistance makes sure that something will last even when it's cleaned with chemicals, oiled, or exposed to other environmental contaminants that are common in electrical uses. Dimensional stability stops panels from twisting or shrinking, which could weaken their integrity.

Certifications for manufacturing quality make sure that foreign standards are met. UL certification makes sure that fire safety rules are followed, and ROHS compliance makes sure that products are safe for the environment. The important selection factors are rounded out by the supplier's technical help, customization options, and delivery reliability.

Top-Grade Phenolic Resin Sheets for Industrial Applications

Premium Grade FR4 Bakelite Composite

This high-performance hybrid material is the best Bakelite sheet technology has to offer today. The FR4 label means that the flame-retardant qualities go beyond the minimum safety standards. The phenolic resin core has glass fiber reinforcements that make it very strong mechanically while still being very good at insulating electrically.

Some important benefits are:

- Outstanding dielectric strength of more than 20 kV/mm

- The temperature range for constant use is from -40°C to 180°C.

- Better steadiness in terms of dimensions when thermal cycling

- Excellent CNC machining qualities for making precise parts

- Low moisture uptake keeps performance from getting worse

- The UL 94 V-0 grade for flame resistance

Advanced pressure molding methods are used in the manufacturing process to make sure that the density of the sheet is the same across its thickness. Quality control systems keep an eye on the amount of resin, the way the fibers are spread out, and the curing conditions to make sure that all output batches have the same properties. This material works great in switchgear uses that can't risk reliability.

Industrial Grade Phenolic Cotton Laminate

This flexible Bakelite sheet is made of phenolic resin and cotton fiber support, making it a cheap way to insulate electrical systems in general. As well as being strong, the cotton cloth is also easy to shape, which is useful for parts with complicated shapes.

Some performance factors are:

- Electrical and mechanical qualities that are equal

- Manufacturing that doesn't cost too much for large orders

- Good thermal stability for continued use up to 150°C

- Excellent capabilities for drilling and punching

- A natural brown color that can be used for decoration

- Chemical resistance to popular solvents used in industry

Controlled curing processes and consistent fiber impregnation are important parts of the production process. Electrical properties, mechanical strength, and thermal performance are all checked using advanced testing procedures. This material is used by companies that make electrical panels and need reliable protection at a good price.

Heavy-Duty Thermosetting Industrial Sheets

These strong Bakelite sheets were made for harsh industrial settings and have improved resin formulations that are made for extreme service conditions. The matrix of the thermosetting plastic creates constant molecular cross-linking that keeps the plastic from melting at high temperatures.

Among the specialized traits are:

- Very high mechanical strength when loaded continuously

- More protection to harsh chemicals in cleaning products

- Even longer service life in harsh settings

- Accurate thickness limits for important uses

- Low rate of thermal expansion

- An improved skin finish for aesthetic reasons

To get close specs on dimensions, manufacturing uses multiple stages of curing and precise grinding. Long-term thermal aging studies and accelerated environmental exposure methods are part of quality assurance testing. Power distribution tools and high-voltage applications have very strict needs that these premium sheets meet.

Global Market Dynamics and Regulatory Landscape

The foreign market for electrical insulation is made up of different regions' tastes and rules. Environmental protection and safety standards are very important in European markets, which is why there is a lot of demand for formulations that are ROHS-compliant and free of halogens. In North America, uses are mostly about UL recognition and fire safety, especially in electrical systems for buildings.

Asian markets put a high value on quality standards that are also cost-effective and can be delivered quickly. The global car industry needs more and more specialized formulations for electric vehicle uses, like parts that insulate battery packs and control heat.

Regulatory moves toward sustainability support the creation of bio-based phenolic resins and composite materials that can be recycled. In response, Chinese companies have put money into study into "green chemistry" and put environmental management systems in all of their factories.

Strategic Purchasing Recommendations for Electrical Manufacturers

To do successful procurement, you need to build relationships with providers who can show they have the technical know-how and consistency in their production. Check out possible vendors' quality management systems, testing skills, and how quickly they respond to customer service requests. Ask for certifications and performance data on the materials to make sure they meet your unique needs.

Think about the total cost of ownership, which includes shipping, keeping supplies, and any quality problems that might happen. Make it clear what the electrical qualities, tolerances for size, and surface finish needs to be. Set up processes for inspecting incoming materials to check their quality and keep track of their traceability.

Create ties with backup suppliers to make sure that you have a steady supply during times of high demand or sudden problems. Talk about framework deals that keep prices stable while still allowing for changes in volume. Regular checks of suppliers help keep quality standards high and find ways to keep getting better.

Industry Trends and Future Outlook

The Bakelite sheet business keeps changing to make products that work better and are better for the environment. New resin chemistries offer better electrical and heat resistance while having less of an effect on the environment. Automation in industrial processes makes things more consistent and lowers the cost of making things.

Digital change makes it easier to see what's going on in the supply chain and help customers. As the market for electric cars grows, it opens up new uses for specialized insulating materials. Smart production technologies make it easier to control quality and make it possible to mass-customize products for specific uses.

Conclusion

Chinese companies that make Bakelite sheets have become world-class suppliers that offer the best quality and value for electrical panel uses. Chinese suppliers are appealing to electrical makers around the world because they offer advanced manufacturing technology, strict quality control, and low prices. To choose the right materials, you need to know exactly what you need and work with suppliers who can show they have the technical know-how and consistency in their making. Electrical shielding materials have a bright future ahead of them as long as they keep improving their performance and being environmentally friendly.

FAQs

What kinds of thicknesses are there for Bakelite sheets used in electrical panels?

The standard thickness runs from 0.5 mm to 50 mm, and the accuracy range is usually ±0.1 mm. Specialized molding or machining methods can be used to make custom thicknesses that meet the needs of a specific application.

How do the quality of Chinese Bakelite sheets compare to those made in Europe?

Materials made by top Chinese companies meet or beat worldwide quality standards. Modern production facilities use advanced technology and quality control methods that are similar to those in Europe. However, they offer lower prices.

What kinds of approvals should I look for when buying materials to insulate my electrical system?

UL certification for electrical safety, ROHS compliance for environmental standards, and ISO 9001 quality management certification are all important certifications. Depending on your job, you may need to get more industry-specific certifications.

Partner with J&Q for Your Bakelite Sheet Manufacturing Needs

You can trust J&Q as your source for Bakelite sheets because they have been making high-quality products for over 20 years and have been dealing internationally for 10 years. We offer a wide range of high-quality phenolic resin sheets to electrical makers, industrial equipment builders, and power sector companies all over the world.

Our integrated approach combines our advanced manufacturing skills with our own logistics business to give you a one-stop service that makes the buying process easier. Our established quality management systems make sure that all of our products work the same way, and our technical engineering support helps you choose the best materials for your needs.

Enjoy the benefits of working with a determined group of people who know how important it is to use the right electrical insulation materials. Email us at info@jhd-material.com to talk about your needs and find out how our experience can help you make more successful electricity panels.

References

Zhang, Wei et al. "Advanced Phenolic Resin Composites for Electrical Applications." Journal of Electrical Materials Engineering, Vol. 45, No. 3, 2023, pp. 234-248.

International Electrotechnical Commission. "IEC 60893-3: Insulating Materials - Industrial Rigid Laminated Sheets Based on Thermosetting Resins." Geneva: IEC Publications, 2022.

Chen, Liu Ming. "Quality Control in Chinese Electrical Insulation Manufacturing." Asia Pacific Electrical Industry Review, Vol. 28, No. 7, 2023, pp. 112-127.

Thompson, Sarah J. "Global Trends in Electrical Panel Materials: A Comprehensive Market Analysis." Electrical Components Quarterly, Vol. 15, No. 2, 2023, pp. 67-84.

Kumar, Rajesh and Wang, Xiaoming. "Comparative Study of International Bakelite Sheet Standards and Testing Methods." Materials Testing International, Vol. 39, No. 4, 2023, pp. 445-462.

European Committee for Standardization. "EN 60893-3: Insulating Materials - Industrial Rigid Laminated Sheets - Requirements for Individual Materials." Brussels: CEN Publications, 2023.