Best Cutting Tools for CNC Machining FR4 Sheets

Carbide end mills, diamond-coated tools, and compression bits made just for composite materials are the best cutting tools for CNC machining FR4 sheets. When working with FR4 sheet surfaces, carbide tools are very precise and last a long time. Diamond-coated tools, on the other hand, last longer when working with the rough glass-fiber support. In electronic manufacturing, choosing the right tools has a big effect on the quality of the surface, the accuracy of the measurements, and the speed of production.

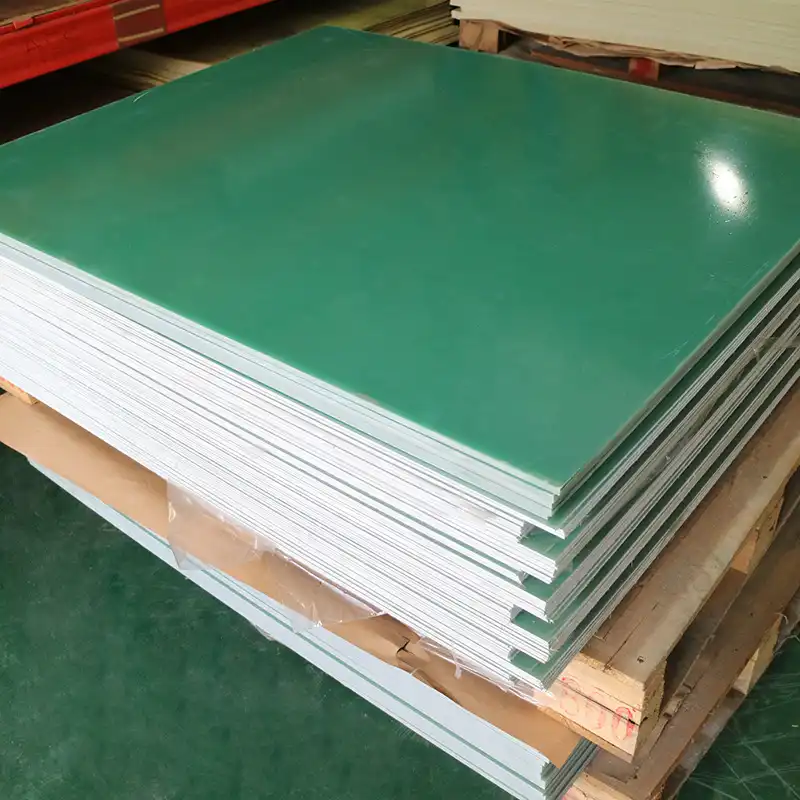

Understanding FR4 Material and CNC Machining Challenges

In current electronics production, FR4 is one of the most useful flame-resistant compounds. This epoxy resin material with glass fibers is very strong, stable at high temperatures, and doesn't conduct electricity. These qualities make it essential for use on circuit boards. When you mix braided glass cloth with thermosetting cement, you get a strong base that can handle harsh working conditions.

But these good qualities make making difficult in their own ways, which engineering managers and technical buying teams need to solve. Normal cutting tools wear out quickly because of the rough glass-fiber support, and the epoxy matrix tends to make too much heat during grinding operations. This increase of heat can make layers separate, which can lead to quality problems that hurt the structure's strength and electricity performance.

Material Properties Affecting Tool Selection

Because of how they are made, fiberglass-reinforced plastic sheets need special ways to be cut. Glass threads are about as hard as carbide materials, which means that they break down tools quickly when they are used for long periods of time. For the layers of glass fabric and epoxy resin that go back and forth, you need tools that can cut through both materials neatly, without pulling out the fibers or spreading the resin.

During CNC processes, controlling the temperature is very important because too much heat can soften the epoxy matrix and make the dimensions less stable. Because they are so sensitive to heat, cutting tools need to have shapes that help chips escape and heat escape quickly. When procurement workers understand these material habits, they can make smart choices about investing in tools that reduce production downtime and waste.

Common Machining Defects and Prevention

When cutting printed circuit board surfaces, delamination is the biggest quality problem that can happen. This split between layers of material usually happens because the tool isn't sharp enough, the cutting forces are too high, or the entry and exit methods aren't right. Sharp cutting edges and the right shape of the tool greatly lower the chance of delamination while keeping the tight limits needed for electrical uses.

Edge chipping along cut surfaces can make it harder to put things together and damage electrical separation. This flaw is generally caused by tools that are too dull, cutting speeds that are too slow, or not enough support for the object. Setting up regular repair plans for tools and keeping an eye on the cutting settings can help stop these quality problems, as well as extend the life of tools and lower running costs.

Top Cutting Tools for CNC Machining FR4 Sheets

To choose the right cutting tools, you need to carefully think about the features of the FR4 sheet, the needs of production, and the quality standards. Depending on the purpose and number needs, different tool materials and shapes have different benefits. When engineering teams know about these choices, they can improve their machining methods while keeping costs low.

Carbide End Mills for Precision Applications

Solid carbide tools are very sharp and don't change size, which is important for accurately cutting electrical parts. Because carbide materials are hard and don't wear down easily, they can cut through glass-fiber support and still keep their sharp cutting edges. When tight standards and high-quality surface finishes are needed, these tools are the best choice.

When compared to regular carbide grades, micro-grain carbide surfaces are tougher, which lowers the chance of tools breaking too soon during tough cutting tasks. When working with rough composite materials, the fine grain structure makes cutting go more smoothly and keeps the edge longer. When working with FR4, uncoated carbide tools often work best because the rough cutting conditions can make the covering less likely to stick.

When cutting composite materials, variable helix end mills help lower friction and improve the quality of the surface. The different helix angles spread the cutting forces out more evenly, which reduces chattering that can lead to a bad surface finish or errors in measurements. When making thin-walled parts or sensitive circuit board features, these geometric features become very important.

Diamond-Coated Tools for Extended Tool Life

The diamond covering technology is very good at protecting against wear from the rough glass-fiber reinforcing. These specialized tools keep their sharp cutting edges for a lot longer than options that aren't covered. This means that tools don't need to be changed as often, which speeds up production. Diamond finishes are great for high-volume production settings where tool life directly affects running costs because they are very hard.

When it comes to composite cutting, polycrystalline diamond (PCD) tools are the hardest to wear down. PCD tools cost more to buy at first, but they can make thousands of parts before they need to be replaced, which makes them a good choice for big production runs. Diamond materials can make cutting edges that are very sharp, which results in a very smooth surface that doesn't need much post-processing.

Chemical vapor deposition (CVD) diamond coats are a cheaper option to PCD tools that still offer better wear protection than carbide that hasn't been covered. These finishes work especially well on complicated shapes where PCD soldering might be hard to do or too expensive. The quality and strength of the finish have a big effect on how well the tool works and how long it lasts.

Compression Cutting Tools for Laminated Materials

Compression bits have spiral directions that are opposite to each other, which makes them cut both up and down at the same time. By adding pressure forces to both sides of layered materials during cutting, this design lowers the chance of delamination. This shape works especially well for making complicated shapes like slots, pockets, or gaps in layered printed circuit boards.

Cutting edges with up-shear and down-shear work together to keep fibers from pulling out and chipping along cut surfaces. The even cutting forces help keep the measurements accurate and make clean lines that can be used in electrical applications. To get the most out of compression cutting shape, it's important to make sure that the speed and feed are optimized correctly.

Spiral compression tools that smoothly switch between upcut and downcut parts can cut through a wide range of FR4 sheet sizes. These advanced shapes can handle the small differences in width that are common in layered substrates while keeping the quality of the surface constant. Because of its unique design, the machine needs to be carefully programmed to get the best cutting settings for each job.

Comparative Analysis: FR4 Cutting Tools Versus Other PCB Materials

Different printed circuit board layers have different machining challenges that affect which tools to use and how to cut. Knowing about these changes in materials helps buying teams make the best decisions about how to use tools for a wide range of products. To get the best results, you need to think about different things for each type of material.

Rogers Material Machining Considerations

Compared to regular epoxy-glass surfaces, high-frequency Rogers materials tend to be softer and more flexible. These materials are often easier to work with, but they need to be cut in a certain way so that heat doesn't build up and the dimensions get messed up. When you work with these high-end materials, you need to cut more slowly and use special chip removal techniques.

When cutting tools are used with ceramic-filled Rogers goods, they break down in different ways than when they are reinforced with glass fiber. Knowing these differences helps engineering teams choose the right finishes and tool materials for production settings that use more than one base. When switching from one type of material to another, tool life predictions and repair plans may need to be changed.

Aluminum-Based PCB Substrates

Metal core printed circuit boards have thin insulating layers and metal backing plates, which makes them difficult to machine in certain ways. The huge difference in the features of organic layers and metal surfaces means that you need tools that can cut both materials well. To get good results, you need to use specialized shapes and cutting settings.

Because the metal core is so good at conducting heat, there are a lot of different ways to apply coolant when working with aluminum-backed surfaces. The fast loss of heat can actually extend the life of the cutting tool, but it needs to be optimized for speed and feed differently than with all-organic materials. Knowing these temperature properties helps set the best settings for cutting so that output goes up.

Polyimide Flexible Circuits

Because they are thin, flexible, and tend to tear instead of cutting neatly, flexible circuit materials pose very different problems. To get a good edge on these materials, you often need to use special fixtures and cutting methods. Not having any glass protection stops rough tool wear, but it makes it harder to move and hold the material.

When working with flexible surfaces, it's even more important to have sharp cutting tools, since any dulling can cause the edges of the cuts to tear or break. Because the smaller pieces of material can't soak up as much heat, controlling the temperature is even more important. For these uses, the selection factors for tools change from wear resistance to keeping their edge.

Best Practices and Maintenance Tips for CNC Machining FR4 Sheets

To get the best results from your machine, you need to pay close attention to the spindle speeds, feed rates, and cooling methods that work best for FR4 sheets. Because glass-fiber reinforcement is rough, it needs more careful cutting settings than metals. Also, because epoxy resins are flexible, they need to be cooled down enough to avoid heat damage.

Spindle Speed and Feed Rate Optimization

When working with composite materials, higher spinning speeds usually lead to a better surface finish. However, tool life must be taken into account. When surface speeds are too high, the rough cutting conditions can lead to quick tool wear, so optimizing the parameters is very important for making things cheaply. Testing with certain mixtures of tool and material helps find the best cutting settings.

The choice of feed rate affects how chips are formed and how much heat is produced during cutting processes. Not enough feed rates can lead to too much grinding and heat building, while too fast of feeds can stress the cutting edges too much and cause the tool to break before it should. The goal is to find the best mix that keeps tool life and part quality high while removing the most material.

Workholding and Fixturing Strategies

When cutting thin layered surfaces that are likely to vibrate and bend, it is very important to have the right support for the part. Most of the time, vacuum fixturing works very well because it holds things securely without putting stress on the clamps, which could damage the material. The even spread of supports helps keep the measurements accurate and stops the item from moving during cutting operations.

When drilling or cutting through layered boards, sacrificial backing materials help keep the layers from coming apart and the edges from breaking. The backing support adds extra support during tool exit, which lowers the risk of tear-out that can lower the quality of the part. Consistent results across production runs are helped by choosing the right backing material and figuring out the best thickness.

Tool Condition Monitoring

Visually checking the state of cutting tools on a regular basis can help find wear patterns and problems before they affect the quality of the part. When you look at cutting edges under a microscope, you can see how the coating is doing and how much wear has happened that you might not have seen with the naked eye. Setting up review plans and wear standards lets you change tools before they break, which lowers quality risks.

When composites are being machined, surface finish loss is often the first sign of tool wear. Checking the surface's hardness and how it looks helps set criteria for when to change a tool based on quality needs instead of time or part count limits. This method makes the best use of tools while keeping the quality of parts uniform across production runs.

Conclusion

Selecting optimal cutting tools for FR4 sheet machining requires careful consideration of material properties, application requirements, and production goals. Carbide and diamond-coated tools each offer distinct advantages depending on volume requirements and quality expectations. Understanding the unique challenges of composite machining enables informed decisions that balance tool costs with productivity and quality objectives. Proper parameter optimization and maintenance practices maximize tool performance while ensuring consistent results across production cycles.

FAQ

What makes FR4 different from other circuit board materials when it comes to machining?

FR4 contains glass-fiber reinforcement that creates abrasive cutting conditions leading to rapid tool wear. The combination of hard glass fibers and softer epoxy resin requires specialized cutting strategies to prevent delamination and achieve quality surface finishes.

How do I know when to replace cutting tools during FR4 machining?

Monitor surface finish quality and edge condition regularly. Increased surface roughness, visible chipping along cut edges, or signs of delamination indicate tool replacement is needed. Establishing inspection schedules based on part count or machining time helps maintain consistent quality.

Can standard metal-cutting tools be used for FR4 materials?

While possible for short runs, standard metal-cutting tools wear rapidly due to the abrasive glass-fiber content. Tools specifically designed for composite materials provide better performance and longer tool life, making them more cost-effective for regular production.

Partner with J&Q for Your FR4 Sheet Machining Solutions

J&Q brings over 20 years of experience in producing high-quality insulating materials and more than 10 years of expertise in international trading. Our comprehensive understanding of FR4 sheet applications enables us to recommend optimal cutting tools and machining strategies tailored to your specific requirements. We maintain extensive partnerships with leading tool manufacturers, ensuring access to the latest cutting technologies and competitive pricing for our customers. Our in-house logistics capabilities provide seamless delivery coordination, while our technical support team offers ongoing assistance to optimize your machining processes. Contact us at info@jhd-material.com to discuss your FR4 sheet supplier needs and discover how our expertise can enhance your production efficiency and quality outcomes.

References

Smith, J.R., "Advanced Cutting Tool Technologies for Composite Material Machining," Journal of Manufacturing Engineering, Vol. 45, No. 3, 2023.

Anderson, M.K. and Liu, C., "Optimization of CNC Parameters for FR4 Substrate Processing in Electronics Manufacturing," International Conference on Electronic Materials Processing, 2023.

Thompson, P.W., "Tool Wear Mechanisms in Glass-Fiber Reinforced Plastic Machining Applications," Composite Materials Technology Review, Vol. 28, No. 2, 2023.

Rodriguez, A.L., "Delamination Prevention Strategies in Laminated Circuit Board Machining," PCB Manufacturing Technology Quarterly, Issue 4, 2023.

Chen, H.Y. and Kumar, S., "Comparative Analysis of Cutting Tool Coatings for Composite Material Applications," Surface Engineering and Tool Technology, Vol. 15, No. 1, 2023.

Williams, R.T., "Economic Analysis of Tool Life Extension in High-Volume Electronic Component Manufacturing," Production Economics and Efficiency Journal, Vol. 32, No. 4, 2023.

Get a complete product list and quotation

J&Q New Composite Materials Company