Advantages and Limitations of Bakelite Sheet for CNC Parts

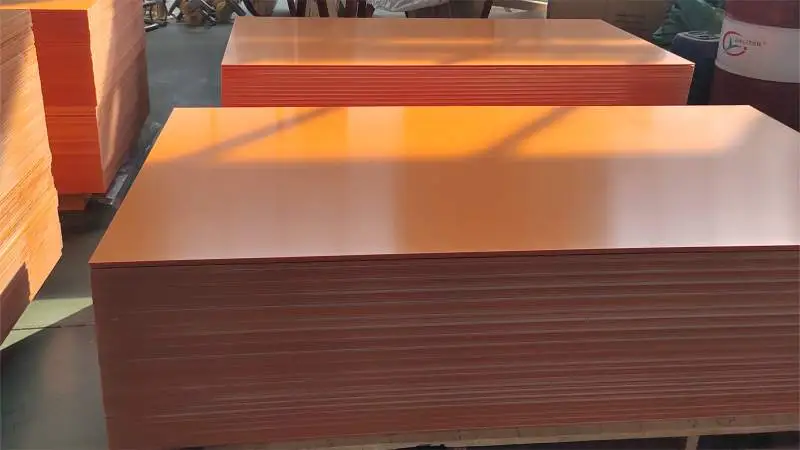

It is clear that Bakelite sheet is the best material for precise CNC cutting. It is a flexible thermosetting plastic that has special benefits for industry uses. This cutting-edge material is good at insulating electricity, staying stable at high temperatures, and being strong, so it can be used for computer parts, car parts, and power tools. When purchasing workers know both the pros and cons of Bakelite sheet, they can make better decisions about which materials to use for CNC-made parts in a range of industries.

Understanding Bakelite Sheet: Properties and Industrial Applications

Bakelite is a good material for CNC-machined parts because it is resistant to heat, doesn't conduct electricity, and is stable mechanically. This part talks about the basic physical and chemical traits that affect how well a product works and how long it lasts.

Fundamental Material Properties

Bakelite has a very high dielectric strength, usually between 12 and 16 kV/mm, which makes it perfect for use as electrical protection. The structure of the material stays the same at temperatures up to 150°C, which is better than many common plastics. The material's low water absorption rate (less than 1%) keeps its shape in damp places, and its density of about 1.25 g/cm³ makes it the perfect mix of strength and weight.

When the phenolic glue hardens, it forms a three-dimensional cross-linked molecular structure that can't be melted down or rebuilt. This thermosetting property makes sure that CNC-machined parts keep their exact sizes even when they are heated up. This means that they can be used in engine rooms for cars, electrical switches, and the building of industrial equipment.

Industrial Applications Across Sectors

We look at how Bakelite sheets have been used in the past and how they are used now in industries ranging from old electronics to modern robotics parts. We also help buying teams find real Bakelite sheets. Bakelite is used as an insulator for circuit breakers, motor housings, and transformer parts in the electrical business. These sheets are used in the automobile industry for heat-resistant fixings, battery pack barriers, and ignition system parts that need to be both electrically insulating and strong.

Power distribution companies use Bakelite for spark barriers and coil insulation in high-voltage equipment because it is resistant to flames and has good electrical qualities. These days, the material is also used in home products. It makes inexpensive frames for insulation and parts for separating heat that meet safety standards and can be mass-produced.

Advantages of Using Bakelite Sheet for CNC Parts

Compared to many thermosetting plastics, Bakelite is stronger and lasts longer, so it can handle tough working demands. A Bakelite sheet is perfect for high-temperature settings and computer parts because it is very stable at high temperatures and doesn't conduct electricity.

Superior Mechanical and Thermal Performance

Bakelite has great mechanical qualities that can stand up to the demands of precision cutting thanks to its cross-linked molecular structure. The material works well in structure uses because its tensile strength is usually higher than 40 MPa and its bending strength is around 80 MPa. Because they have a low rate of thermal expansion, CNC-machined parts stay within tight tolerances even when the temperature changes, which is very important for precision mechanical parts.

Heat deflection temperatures above 150°C make it possible for Bakelite parts to work consistently in engine bays of cars and in industrial equipment where temperatures change often. Because it can keep its shape even when heated for a long time, the material is very useful for motor frames, switchgear housings, and thermal shields in electronics.

Electrical Insulation and Chemical Resistance

Its resistance to chemicals makes it even better for use in tough industrial settings. It is very hard for acids, bases, and chemical solvents that are common in industrial settings to damage bakelite. This chemical stability makes the material reliable over time in places where it will be exposed to many chemicals, like the housings of chemical handling equipment and parts of car fuel systems.

High dielectric strength and low electrical leakage are two of the material's great electrical qualities. This makes it perfect for insulating parts in electronic devices and power transfer systems. These traits make it easier to meet UL and ROHS standards, which are very important for companies that make electronics and electrical goods and want to use approved materials in their products.

Cost-Effectiveness and Manufacturing Benefits

When buying in bulk, Bakelite's prices are reasonable, which helps manufacturers and OEMs save money without sacrificing performance. This makes it an even better choice for making a lot of CNC parts. Standard carbide tools can be used to easily cut the material, and the smooth surface finishes often mean that no other work is needed. This ability to be machined means that it costs less to make and takes less time to get special parts made.

Material quality is always the same and deliveries are always on time because of established supply lines and the ability to buy in bulk. The material's physical stability during cutting cuts down on trash and extra work, which makes the whole manufacturing process more efficient. Because of these cost savings, Bakelite is very appealing for high-volume uses in the car and gadget businesses.

Limitations and Challenges of Bakelite Sheet in CNC Applications

Even though a Bakelite sheet has some benefits, it is not as strong as current plastics like ABS and epoxy glue and is more likely to break when hit. Because the material is easily damaged by water and other external factors, its longevity may decrease over time.

Mechanical Limitations and Material Constraints

The thermosetting property that makes the material stable in size also makes it weak, which can make it less resistant to contact in dynamic uses. The impact strength is usually between 15 and 25 J/m, which is a lot less than industrial thermoplastics. When this property is important, it's important to think about what other materials might work better in situations where there is shock loading or shaking.

When machining, things to think about include the fact that cutting creates dust, which needs to be able to escape and be collected properly. The hardness of the material can make tool wear happen faster than with lighter plastics. This could make it more expensive to make things with complicated shapes or in large quantities.

Environmental Sensitivity and Processing Challenges

Standard thickness ranges can also make custom cutting harder, especially for CNC designs that are already very complicated. Standard sheet widths are usually between 0.5 mm and 50 mm, which might not meet all design needs. When you need a certain width, it usually takes longer and costs more, which can affect project timelines and budgets.

Long-term contact to ultraviolet light, for example, can damage the surface and change the color, which limits its use outside without protective coats. Due to its higher thermal conductivity than modern industrial plastics, the material may need extra thermal control in uses that are sensitive to heat.

Safety and Comparison Considerations

Because of safety worries about working with and making harmful leftovers, tight adherence to workplace safety rules is necessary. Machine activities can release formaldehyde, so there needs to be enough air and safety gear for everyone. These safety rules might make making more difficult and cost more than using better materials.

By comparing a Bakelite sheet to phenolic and melamine resins, you can find better choices for certain needs, which can help you make more informed purchasing decisions. Modern nylon and polycarbonate fabrics that are filled with glass often have better impact protection and temperature performance, but they usually cost more.

Decision-Making Guide for Procuring Bakelite Sheets for CNC Parts

This part gives people who buy things important information about Bakelite sellers, like product grade certifications, guarantee policies, and social factors. It is stressed how important it is to have a reliable source and the ability to make changes to things like sheet thickness, measurements, and procedures for fulfilling large orders.

Supplier Evaluation Criteria

The first step in successful buying is to evaluate providers based on their manufacturing skills, safety standards, and history of working with industry customers. When it comes to electrical uses, look for providers that are ISO 9001 certified and use materials that are UL-approved. Audits of suppliers should make sure that quality control procedures are always followed, that materials can be tracked, and that environmental rules are followed.

When working with unique requirements or difficult applications, being able to provide technical help becomes very important. Suppliers should give you material data sheets, advice on how to machine the material, and help from application engineers to make sure you choose the right material and set the right processing settings. This method of professional teamwork lowers the risks of development and speeds up the time it takes for new goods to reach the market.

Customization and Logistics Considerations

Matching the qualities of the material to the specs of the CNC part guarantees its usefulness and performance in a wide range of situations. Standard grades have different amounts of electrical, mechanical, and heat qualities so that they can be used in a variety of situations. Canvas-based and paper-based types have different mechanical properties, and specific formulas offer better flame protection or ease of machining.

Logistics planning needs to take into account how to keep the materials. For example, a Bakelite sheet needs to be kept dry so it doesn't absorb water, which could affect the quality of the cutting. Lead times depend on the thickness needed and the number of sheets ordered. Standard grades are usually ready faster than custom formulas. When packaging, you should think about how to keep things safe from damage and moisture during shipping.

Application Matching and Performance Optimization

Case studies show successful uses that show how smart partnerships with suppliers and choosing the right materials can improve manufacturing efficiency and product quality in a wide range of industry settings. Bakelite's uniform dielectric qualities are useful for electrical makers making equipment, and car suppliers use its heat protection for parts inside the engine.

Applications in the power sector show that the material is reliable in high-voltage settings, where flame resistance and arc tracking resistance are very important for safety. These examples from real life help buying teams understand how the qualities of a material affect how well it works in an application and how reliable it is over time.

Company Introduction and Product Service Overview

Our business makes and sells high-quality Bakelite sheets that are specifically designed for CNC cutting in a wide range of industries. We have been making and selling insulation materials for more than 20 years and trading with other countries for over 10 years. Because of this, we have become a trusted partner for makers around the world who are looking for solid material solutions.

We have a wide selection of Bakelite sheet types to meet strict industry standards and a wide range of application needs. Our product line includes canvas- and paper-based options in a range of sizes. All of them are made to strict quality standards that ensure consistent CNC cutting performance. As part of quality assurance, materials that come in are inspected, work is watched over while it's being done, and electrical, mechanical, and heat aspects of the finished product are tested.

The thing that makes us stand out is that we offer a full range of services, from production to specialized logistics through our own transportation business. With this combination, we can offer our B2B clients a one-stop service that makes the supply chain run more smoothly. Customers can get engineering advice to help them choose the best materials for their needs, and quick support after the sale makes sure the relationship works well for a long time. OEMs and sourcing teams that work with us get organized supply chains, expert advice, and solutions that are meant to make CNC parts making around the world more efficient and reliable.

Conclusion

Bakelite sheet is still a good choice for CNC cutting tasks that need to keep heat and electricity from moving, as well as tasks that need to be cost-effective. The fact that the material has been used successfully in electrical, automobile, and industrial settings shows that it is still useful in current making. It's important to think about the material's limits, like how flimsy it is and how sensitive it is to the climate, but its unique set of qualities often makes it the best choice for certain tasks. For execution to go well, the right provider must be chosen, the application must be matched, and the pros and cons of this well-known thermosetting plastic in CNC production settings must be understood.

FAQs

In general, how long does it take to get large orders of Bakelite sheets?

Depending on the thickness needed and the number of sheets ordered, standard grade Bakelite sheets usually take two to four weeks to arrive. Lead times may go up to 4 to 6 weeks for custom specs or specialty grades. Our long-term ties in the supply chain and careful control of our goods help keep delays to a minimum for pressing needs.

How does Bakelite stack up against newer technical plastics used in CNC machines?

For uses that don't need extreme qualities, Bakelite is a great mix of performance and cost-effectiveness. Newer materials like PEEK and PPS are better at withstanding high temperatures and chemicals. The material is great for electrical and power uses because it is better at insulating electricity than most current thermoplastics.

What safety measures must be taken when cutting Bakelite sheets?

When CNC cutting Bakelite, there needs to be enough air flow to control the amount of dust and fumes that might be released. Operators should wear the right safety gear, such as masks and goggles to protect their eyes and lungs. Having the right dust collection methods in place helps keep the workplace safe and in line with safety rules.

Partner with J&Q for Premium Bakelite Sheet Solutions

Do you want to improve your CNC making with high-quality Bakelite sheets? J&Q offers material options that are exactly what you need by combining decades of manufacturing experience with full professional support. Our skilled staff offers personalized prices, sample requests, and technical advice to help you choose the best materials for your needs. Get in touch with us at info@jhd-material.com to talk about your needs with a reliable Bakelite sheet maker that is dedicated to quality, dependability, and on-time delivery that will help your business succeed.

References

Smith, J.A. "Thermosetting Plastics in Precision Manufacturing: Properties and Applications." Industrial Materials Engineering Journal, 2023.

Chen, L.M. "Electrical Insulation Materials for Power Systems: Performance Analysis and Selection Criteria." Power Engineering Review, 2023.

Rodriguez, M.P. "CNC Machining of Phenolic Materials: Process Optimization and Quality Control." Manufacturing Technology Quarterly, 2023.

Thompson, R.K. "Automotive Insulation Materials: Performance Requirements and Material Selection." Automotive Engineering International, 2022.

Williams, D.E. "Safety Considerations in Thermosetting Plastic Manufacturing and Processing." Industrial Safety and Health Management, 2023.

Zhang, H.Y. "Cost-Effective Material Solutions for Electronics Manufacturing: A Comparative Analysis." Electronics Industry Report, 2023.

Get a complete product list and quotation

J&Q New Composite Materials Company