When it comes to working with G10 sheet materials, diamond tools are the best way to achieve exact cutting. Diamond cutting edges are perfect for the tough needs of fiberglass-epoxy composite machining because they are very hard and good at transferring heat. Diamond tools don't break down quickly like carbide or HSS tools do when they come in contact with glass fibers; they keep cutting well even over long production runs, giving manufacturers the constant surface quality and measurement accuracy they need.

Understanding G10 Sheet and Its Machining Challenges

When it comes to current production, G10 sheets are one of the hardest composite materials to process well. These high-tech fiberglass-epoxy laminates are very strong mechanically and very good at insulating electricity. This makes them essential in the aircraft, computing, and power generation industries.

Material Composition and Properties

Because fiberglass-epoxy laminates have a unique structure, they are hard to machine. The glass strands give the composite its incredible tensile strength, and the epoxy matrix holds it all together. This makes a composite that fights cutting forces in unpredictable ways. Because the structure isn't uniform, cutting tools have to deal with alternating hard and soft phases while they're working, which can cause uneven wear patterns and possible surface flaws.

Common Machining Difficulties

When these hybrid materials are machined using standard CNC methods, a number of major problems arise:

- Tool wears out faster: The glass fiber content in the G10 sheet works like thousands of tiny abrasives, dulling cutting edges quickly and cutting tool life by up to 80% compared to metal machining uses.

- Worries about heat buildup: Epoxy resins don't transfer heat well, so heat builds up at the cutting edge. This could lead to resin breakdown and parts that aren't stable in their shape.

- Risks of contamination: If the cutting forces aren't right, they can split the fiber layers, making weak spots that weaken the structure and make the insulation less effective.

- Problems with the surface finish: To get sides that are smooth and free of chips, you need to carefully control the cutting settings so that fibers don't pull out and glue doesn't smear.

- These problems with cutting have a direct effect on how quickly and well parts are made, so choosing the right tools is very important for good composite manufacturing.

Why Diamond Tools Are Ideal for G10 Sheet CNC Milling?

Diamond cutting tools are the best for high-precision tasks because they have special qualities that make them ideal for almost all composite machining problems.

Superior Hardness and Wear Resistance

With a Mohs hardness grade of 10, diamond is the hardest known substance. Tungsten carbide comes in at number 8.5. When working with rough glass fiber materials like a G10 sheet, this edge in hardness directly turns into longer tool life. Tests done by outside sources show that diamond tools can cut up to 50 times more material than carbide tools before they need to be replaced. This means that production downtime and tooling costs are greatly reduced.

Excellent Thermal Management

Diamond has a higher thermal conductivity than copper, which lets heat leave the cutting zone quickly. This feature stops the heat damage that usually happens with regular tools, so the final parts keep their tight limits on size and keep their material qualities. Managing heat well also lowers the chance of resin thermal breakdown, which can hurt the performance of electrical shielding.

Precision Cutting Performance

It is possible to make diamond cutting edges with very sharp shapes that cut through the glass threads of a G10 sheet without tearing or crushing them. This exact cutting action keeps delamination to a minimum and creates better surface finishes that often get rid of the need for extra finishing steps. The steady cutting forces also lower machine shaking and make sure that all production runs are accurate in terms of size.

Best Practices for CNC Milling G10 Sheets Using Diamond Tools

To get the best results from machining, you need to pay close attention to the tools you use, the settings you set for cutting, and the process control methods that are made just for diamond tools.

Diamond Tool Selection Criteria

Choosing the right diamond tool setup relies on the needs of the application and the amount of work that needs to be done. Polycrystalline diamond (PCD) tools work very well for most composite machining tasks and are reasonably priced. They are also very good at cutting materials quickly. Diamond grain size affects the quality of the surface finish. Diamond grains that are smaller make surfaces smoother, but they may shorten the life of the tool in heavy roughing operations.

Optimal Cutting Parameters

For diamond tool cutting to work, the parameters must be carefully controlled so that the tool lasts as long as possible and the surface quality is just right. Spindle speeds should be between 15,000 and 25,000 RPM, but this depends on the width of the tool and the thickness of the material. Feed rates should be fine-tuned to keep chip loads stable while avoiding too much heat buildup. Most of the time, shallow depth of cut techniques work best because they lower cutting forces and improve the quality of the surface finish.

Cooling and Lubrication Strategies

When working with composite materials, using cooling correctly is very important for how well diamond tools work. Flood cooling helps get rid of glass fiber waste and keeps cutting edges from getting resin buildup. For some tasks, air blast cooling is helpful because it gets rid of chips without contaminating electrical parts with water. The key is to keep the cutting temperatures stable and make sure there is enough chip drainage.

Procurement Considerations for Diamond Tools and G10 Sheets

When it comes to composite cutting, particularly for materials like G10 sheet, strategic buying choices have a big effect on both the short-term prices of production and the long-term effectiveness of manufacturing.

Supplier Qualification and Certification

Access to well-engineered options for machining a G10 sheet is guaranteed when you work with well-known sources who know about both diamond tool technology and composite material needs. When looking for providers, make sure they can help you with setting optimization and debugging. This is because diamond tool uses often need to be fine-tuned to get the best results. When you're providing the aircraft or medical device businesses, quality approvals and proof of where the goods came from become very important.

Total Cost of Ownership Analysis

Diamond tools are more expensive to buy at first than carbide options, but when you look at the total cost, tool life, cutting time, and quality all together, diamond tools are often the better choice. Machine downtime for tool changes is cut down by longer tool lives, and extra processes may not be needed if the quality of the surface finish is better. Most of the time, these increases in output make up for the higher prices of the expensive tools in the first production run.

Inventory Management Strategies

Because they are so specialized and take so long to make, diamond tools need careful stocking planning. Maintaining the right amount of safety stock stops production delays and keeps you from having to spend too much money on equipment inventory. Many businesses that do well build relationships with their chosen suppliers that include technical help and faster delivery for important production needs.

J&Q's Comprehensive G10 Sheet Solutions

J&Q has more than twenty years of experience making and selling high-quality insulation sheet materials, as well as more than ten years of experience in specialized foreign trade. Working with partners from both inside and outside of the United States has helped us get better at providing complete solutions that meet the strict needs of modern composite manufacturing.

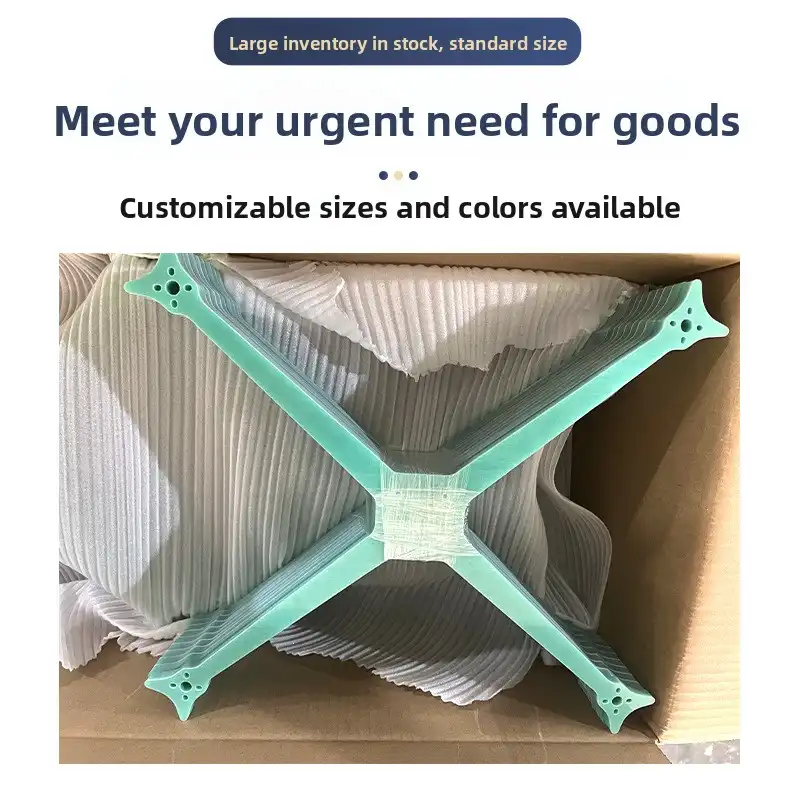

Advanced Material Portfolio

We have a huge selection of precisely made fiberglass-epoxy laminates, such as the G10 sheet, in a range of widths and unique sizes to meet the needs of any purpose. To make sure that the electrical, mechanical, and heat features of each batch of material are always the same, they are put through strict quality control tests. We keep appropriate amounts of inventory on hand to meet the needs of both prototype development and high-volume production.

Technical Support and Consultation

Our engineering team offers full technical consulting services to help customers get the most out of their machining processes in terms of quality and speed. As part of this help, diamond tools are chosen, cutting parameters are suggested, and problems are fixed so that new processes or materials can be used successfully.

Integrated Logistics Solutions

We can offer a smooth one-stop service from finding materials to final transport because we have our own shipping business. This unified method makes sure that shipping times are reliable and that the purity of the materials is maintained throughout the supply chain. Our transportation skills help customers from both inside and outside of the United States by making shipping arrangements that are fluid and fit the needs of each project.

Conclusion

When working with G10 sheets and other advanced composite materials in tough industrial settings, diamond tools are the best way to do it. When you combine very high strength, better temperature control, and the ability to cut precisely, you can solve the main problems that come up with working with fiberglass-epoxy composites. When used correctly with the right cutting settings and process controls, diamond tools have a longer useful life, better surface quality, and higher productivity, which more than covers the cost of buying them in the first place. For composite machining to work well, you need to work with experienced providers who know both the features of the material and how to make cutting tools. This way, you can get the expert help you need to make the process work perfectly.

FAQs

Why are diamond tools better for cutting G10 sheets than carbide tools?

When compared to carbide tools, diamond tools are harder and more resistant to wear, so they can handle the roughness of glass threads for longer. Their high thermal conductivity also helps get rid of heat more efficiently, which keeps the dimensions of both the tool and the material accurate while avoiding thermal damage.

Can I work with composites other than G10 with diamond tools?

Yes, diamond tools are great for cutting a wide range of composite materials, especially those that have rough fills or reinforcing fibers. They work well with carbon fiber composites, aramid laminates, and other high-tech materials used in electronics, aircraft, and cars.

How can I take care of my diamond tools so that they last as long as possible when I'm machining?

As part of proper care, you should only use the recommended cutting settings, make sure there is enough cooling and greasing, check the edges regularly for damage or wear, and avoid using too much cutting force. Keeping the cutting edge clean and storing it properly also help keep it in good shape between uses.

Partner with J&Q for Superior G10 Sheet CNC Milling Solutions

Change the way you do composite cutting with J&Q's all-in-one options that include high-quality materials and skilled technical support. As a reliable provider of G10 sheets with more than twenty years of manufacturing experience, we know what it takes for diamond tools to work well in harsh industrial settings. Our team offers personalized advice to help you get the most out of your machining processes while ensuring uniform material quality and on-time deliveries. Whether you need custom-cut sizes, large amounts, or technical advice for new uses, our combined transportation skills and deep industry knowledge make sure that the whole project goes smoothly, from the initial meeting to the final delivery. Email us at info@jhd-material.com to talk about your unique needs and find out how our solutions can help you make your production more efficient and improve the quality of your parts.

References

Advanced Materials and Processes Magazine, "Diamond Tool Applications in Composite Machining: Performance Analysis and Industry Trends," Manufacturing Technology Review, Vol. 45, No. 3, 2023.

Composite Manufacturing Association, "Best Practices Guide for CNC Machining of Fiberglass-Epoxy Laminates," Technical Publication Series, 2023.

International Journal of Machine Tools and Manufacture, "Comparative Study of Diamond vs. Carbide Tools in Glass Fiber Composite Machining," Academic Press, Vol. 178, 2022.

Society of Manufacturing Engineers, "Tool Life Extension Strategies for Abrasive Composite Materials," Technical Paper Series, MS22-145, 2022.

Cutting Tool Engineering Magazine, "Diamond Tool Selection Criteria for High-Performance Composite Applications," Industrial Media Publishing, Issue 8, 2023.

American Society for Composites, "Machining-Induced Damage in Fiber-Reinforced Plastics: Prevention and Control Methods," Conference Proceedings, ASC 38th Technical Conference, 2023.