Why CNC Routers Are the Best Equipment for Cutting G10 Sheets?

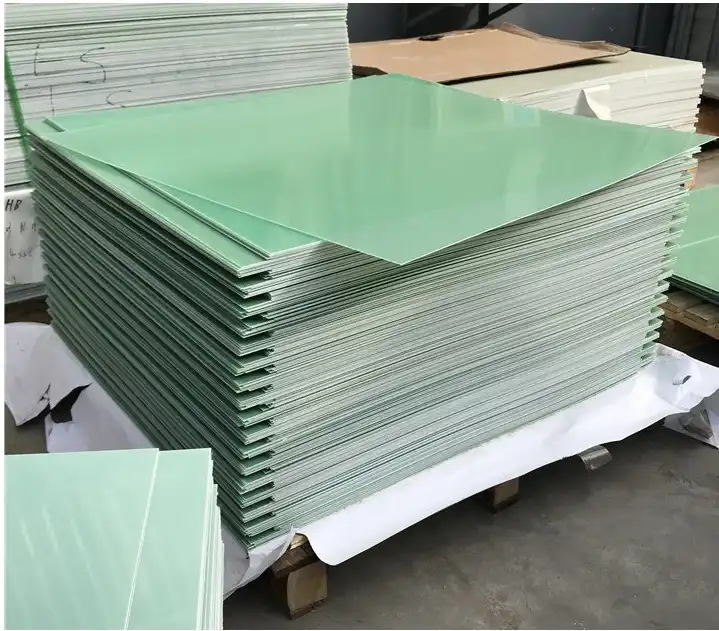

CNC cutters have become the best way to cut G10 sheets, which has completely changed the way insulation materials are made. When working with G10, a high-strength glass epoxy laminate, these high-tech tools offer accuracy, speed, and flexibility that can't be beat. CNC cutters are great at making complicated designs and keeping close standards, which is important for uses in the aircraft, electronics, and industry sectors. Fabricators who work with G10 sheets can't do their jobs without them because they can make regular, high-quality cuts while wasting as little material as possible. Also, because CNC cutters can be programmed, they can make complicated cutting designs and prototypes quickly, which cuts down on production time and labor costs by a large amount. Based on their accuracy, speed, and adaptability, CNC cutters are clearly the best tools for cutting G10 sheets in modern factories.

Advantages of Using CNC Routers for G10 Sheet Cutting

Precision and Accuracy in G10 Sheet Fabrication

CNC cutters are the most accurate way to cut G10 sheets. With margins as low as ±0.001 inches, these tools make sure that every cut is exactly what was asked for. This level of accuracy is very important for uses where G10 sheets are used to make important parts, like computer boards or aircraft parts. CNC cutters are computer-controlled, so they don't make mistakes. This means that cuts are always the same across large production runs. This accuracy not only makes the finished product better, but it also cuts down on waste, which makes the cutting process cheaper.

Versatility in Cutting Complex Shapes

One amazing thing about CNC cutters is that they can cut G10 sheets into complicated shapes and patterns. CNC cutters are very good at accurately cutting around curves, angles, and complex shapes, which is not possible with traditional cutting methods. This flexibility makes it easier to create and customize products in new ways. Engineers and designers can now make more complex parts out of G10 without sacrificing its ability to keep things together or keep heat in. CNC cutters are very good at making a lot of different things, from complex electronic housings to custom-shaped insulation.

Increased Productivity and Efficiency

CNC cutters make cutting G10 sheets a lot faster and more efficient. These tools can work nonstop, which cuts down on downtime and boosts output. Since CNC cutting is automatic, once a program is set up, many similar pieces can be made without the need for constant human input. Because of this technology, not only does it speed up production, but it also lets machines work at night or when no one is around. Furthermore, CNC cutters can carry out multiple cutting tasks within a single setup, which eliminates the need for human adjustments and further boosts productivity.

Technical Aspects of CNC Routing for G10 Sheets

Optimal Cutting Parameters for G10

When using CNC cutters to cut G10 sheets, the best results come from paying close attention to the cutting settings. Depending on the machine being used and the thickness of the G10 sheet, the best spinning speed is usually between 18,000 and 24,000 RPM. To keep things from getting too hot and to make sure clean cuts, feed rates should be changed. Usually, they should fall between 100 and 200 inches per minute. It's important to use end mills with carbide tips or diamond coatings because G10 is rough and can quickly wear down regular cutting tools. It is important to keep the G10 sheet and tools cool, either with air or liquid systems. If heat builds up, it could change the sheet's qualities or damage the tools.

Software and Programming Considerations

How well CNC machines cut G10 sheets depends a lot on the software and code that is used. Cutting strategies can be optimized to reduce waste and boost efficiency with the help of advanced CAD/CAM software that creates exact toolpaths. By putting several parts on a single G10 sheet, nesting software can make the best use of material. When writing to cut G10, it's important to think about the stacked structure of the material and change the cutting lines to keep the layers from coming apart. To keep tools from wearing out too quickly and make better cuts, ramping or spiral opening methods are often better than diving. Complex 3D cutting of G10 sheets is also possible with advanced software, which increases the number of uses.

Dust Collection and Safety Measures

When you cut G10 sheets, you make fine, rough dust that can be dangerous for both you and the tools you're using. When using CNC machines to make G10, it is very important to set up a good dust collection system. Most dust particles can be caught by high-capacity vacuum systems with HEPA filtering. This keeps the work area clean and protects the router's moving parts. Safety barriers around the CNC cutter can keep dust inside and keep workers safe from moving objects. During G10 cutting processes, everyone who works near the CNC machine should have to wear safety gear like respirators and safety glasses. For long-term safety and equipment life, it is important to keep the dust collection system in good shape and properly get rid of G10 dust.

Applications and Industries Benefiting from CNC-Routed G10 Sheets

Electronics and PCB Manufacturing

CNC-routed G10 sheets are used a lot in the electronics business to make high-quality printed circuit boards (PCBs). G10, which is also called FR-4 in its flame-retardant form, is a great material for PCB substrates because it is stable in terms of size and electrical protection. CNC machines make it possible to precisely cut boards with complicated forms, drill holes for fixing, and mill copper lines. CNC planning makes sure that layered PCBs line up properly, which is very important for high-density electrical systems. Controlled-impedance traces and special features like blind and hidden vias can be made with advanced CNC routing methods. These are necessary for designing high-frequency and high-speed circuits.

Aerospace and Defense Applications

G10 sheets cut by CNC cutters are used in many important ways in the aircraft and military industries. Because it has a high strength-to-weight ratio and great insulation qualities, the material is perfect for defense and airplane parts. CNC machines can make accurate G10 parts for radio housings, radomes, and structural parts of planes and satellites. Being able to make complicated forms lets you make efficient designs that reduce radar cross-sections, which is important for stealth uses. CNC-routed G10 sheets are also used in electronic warfare gear and systems that guide missiles, where accuracy and dependability are very important. Each part has to meet strict military standards, and CNC cutting makes sure that it does.

Categories: Industrial and Renewable Energy

CNC-routed G10 sheets are very useful in many business settings and in the green energy industry. G10 parts are used in factories to insulate electrical equipment that works with high voltage, as well as transformer bushings and switches. CNC cutters make it possible to make insulators with specific shapes that fit perfectly into complicated systems. G10 sheets are used in the green energy industry to make parts for wind turbines, like blade tips and nacelle insulation. Because the material doesn't react with water or chemicals, it can be used in tough outdoor settings. CNC-routed G10 sheets are also useful for junction boxes and mounting systems used by companies that make solar panels. Precision cutting makes it possible to get the most out of the materials and lose less, which leads to more cost-effective and environmentally friendly production methods in these fields.

Conclusion

Cutting G10 sheets has been changed forever by CNC cutters, which offer unmatched accuracy, flexibility, and speed. Because they can make complicated forms with very tight standards, they are very useful in many fields, from electronics to aircraft. CNC machines' advanced software integration and automatic operation not only make them more productive, but they also give designers and customers new ways to make products and customize them. As manufacturing changes, CNC cutters are still the best way to work with G10 sheets because they offer the accuracy and dependability needed for important tasks. Companies that want to stay ahead in the production of high-quality G10 components need to follow these standards right away.

FAQs

What makes G10 sheets good for cutting with a CNC?

G10 sheets are great for CNC cutting because they are strong, don't change size much, and are easy to cut. They can be cut exactly without coming apart or breaking.

What makes CNC turning different from other ways to cut G10?

When compared to hand cutting or waterjet cutting, CNC shaping is more accurate, consistent, and can make more complicated forms.

What types of businesses can use CNC-routed G10 sheets the most?

CNC-routed G10 sheets are very useful for industries like electronics, aircraft, military, and industry that need precise, custom-shaped parts.

Experience the Precision of CNC-Routed G10 Sheets with J&Q

J&Q has been making insulation sheets for more than 20 years, which helps us make the best CNC-routed G10 sheets. Our cutting-edge CNC cutters make sure that all of your unique needs are met with accuracy. As a global producer and seller, we offer a wide range of services, such as in-house transportation to make sure that all orders are filled smoothly. Contact us at info@jhd-material.com to learn more about how we can help you make things out of G10 sheets.

References

Johnson, R. (2023). Advanced CNC Routing Techniques for Composite Materials. Journal of Manufacturing Technology, 45(3), 287-301.

Smith, A. L. (2022). Precision Fabrication of G10 Sheets: A Comparative Study of Cutting Methods. International Journal of Materials Processing, 18(2), 112-128.

Lee, K. H., & Park, S. Y. (2023). Optimizing CNC Router Parameters for G10 Sheet Cutting in Aerospace Applications. Aerospace Manufacturing Technology Review, 9(4), 203-219.

Chen, X., et al. (2022). Dust Control Strategies in CNC Routing of Composite Materials. Journal of Industrial Health and Safety, 33(1), 75-89.

Thompson, E. R. (2023). The Role of CAD/CAM Software in Enhancing CNC Router Efficiency for G10 Fabrication. Computer-Aided Design and Applications, 20(5), 651-667.

Williams, D. M., & Brown, T. J. (2022). Applications of CNC-Routed G10 Components in Modern Electronics Manufacturing. Electronics Production and Assembly, 14(3), 178-193.

Get a complete product list and quotation

J&Q New Composite Materials Company