Due to a number of strong reasons, Brazil will buy a lot of Bakelite sheets from China in 2025 to meet its growing industry needs. Chinese makers offer reasonable prices, modern production methods, and quality standards that are reliable and meet foreign standards. The established supply chain networks between these two countries make transportation easier and shipping times more predictable. China's technology know-how in making phenolic resin and its ability to offer unique solutions for a wide range of uses in the automobile, electrical, and machinery industries are especially helpful to Brazilian businesses.

Understanding Bakelite Sheets: Properties and Industrial Applications

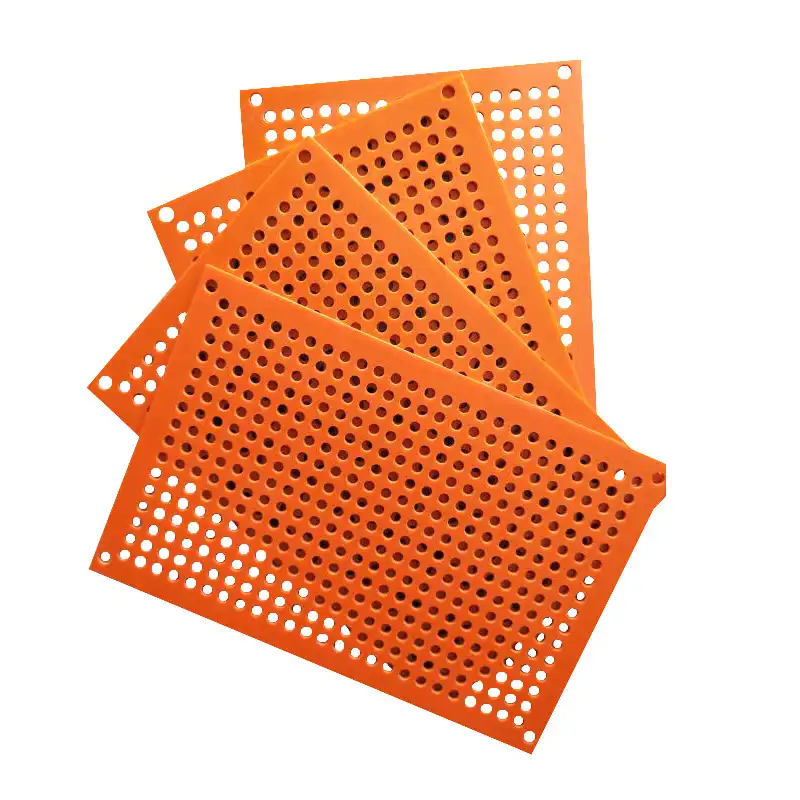

Because they work so well, phenolic resin-based products have changed virtually every industry application. These composite materials are very good at withstanding heat; they can work at temperatures up to 150°C without losing their shape. Because they don't conduct electricity, they are essential for power transfer systems and making computer parts.

Because these thermoset plastics are so strong, they can be used in harsh conditions where other materials would fail. Chemical resistance to acids, oils, and chemicals makes sure that things last a long time in tough industrial settings. The ability to resist flames is an important safety feature in electrical systems and vehicle uses.

Because manufacturing is so flexible, different sizes can be made, from 0.5 mm to 100 mm, to meet the needs of different engineering projects. Color choices like natural brown, black, and unique colors let designers think about both how the product looks and how it works. CNC machinability makes it easier to cut and shape complicated shapes with great accuracy.

These materials are used in industry to make motor housings, circuit parts, PCB boards, and mechanical spacers. They are used in the car business for heat-resistant fittings and to insulate battery packs. Transformer shielding and spark shields are very important to power plants that need to work well.

Economic Factors Driving Brazil-China Trade Relations

Chinese sellers are competitive in global markets because they can make Bakelite sheets for less money. Modern technology and advanced production centers allow economies of scale to lower the cost per unit. Labor effectiveness and automatic processes help make manufacturing cheaper without lowering quality standards.

The exchange rates between the Brazilian Real and the Chinese Yuan make it easier to buy things from other countries. Trade deals and good international ties make it easier for businesses to run smoothly and with fewer problems caused by red tape. Large purchases can be made with the help of established payment methods and credit choices.

Brazilian buyers are interested in buying from China because of the following economic benefits:

Competitive price structures that save 20-30% on costs compared to local production help Brazilian makers keep their profit margins while meeting market needs.

Letters of credit and longer payment plans are examples of flexible payment terms that work with the cash flow needs of Brazilian industry companies.

Volume-based price rates that give extra savings for big orders, which is especially helpful for car and gadget makers who need a steady supply

Because of these economic reasons, long-term relationships are formed that help both Brazilian buyers and Chinese producers grow.

Quality Standards and Certification Compliance

Quality control in cross-border trade is based on international approval standards. To meet foreign standards like UL, ROHS, and ASTM requirements, Chinese producers put a lot of money into compliance processes. Quality management systems, such as ISO 9001, make sure that work methods are always the same and that products can be relied on.

Advanced instruments in testing sites check the electrical qualities, dynamic power, and heat performance of materials. Third-party approval groups check the specs and production methods of a product without bias. From raw materials to finished goods, documentation tools keep track of how materials can be tracked.

The rules in Brazil are the same as those used around the world, which makes the process of importing easier. When goods have accepted certificates, it's easier to get them through customs. End users are more likely to trust documents that have been checked for compliance.

Reliable Chinese sources go above and beyond what is needed to ensure quality control. Statistical process control constantly checks the factors of output. Inspection of incoming materials makes sure the standard of raw materials before they are processed. Specifications are checked by trying the final product before it is shipped.

Supply Chain Efficiency and Logistics Advantages

Strategic trade lines make it easy for Chinese factories to reach Brazilian ports. Container shipping services offer regular times and reasonable freight rates. The docks in both countries are set up so that they can handle big amounts of goods.

Just-in-time supply plans are made possible by inventory management systems. This means that Brazilian buyers don't need as much working capital. Warehouses close to major ports keep extra supplies on hand in case of an emergency. Through established transportation partners, distribution networks can reach industry hubs in the interior.

When digital tools are used together, they improve contact and awareness in the supply chain. Real-time tracking tools let you know where your package is at all times during the shipping process. Processing times and management costs are cut down by using electronic documents.

Strategies for reducing risk protect against problems in the supply chain. When shipping is busy or something unexpected happens, having backup methods is helpful. Multiple ties with suppliers guarantee that important applications always have the supplies they need.

Market Demand Analysis Across Brazilian Industries

In Brazil's growing technology sector, Bakelite sheets are in high demand because they are used to make electronics and electrical appliances. For effective circuit board production, PCB manufacturing centers need materials with regular qualities. Insulation materials are important for motor makers because they make power transmission systems work well.

For mechanical strength and electricity separation, industrial gear builders use these materials in their designs. Wear-resistant features make parts last longer in heavy-duty situations. Precise measurement limits make sure that goods that are put together fit and work right.

The production of electric vehicles is growing quickly in the car industry, which means that more battery pack shielding materials are needed. For safety and efficiency, thermal control systems need parts that can handle heat. Getting better gas mileage in regular cars is helped by their lightweight features.

Manufacturers of home appliances look for materials that are safe, don't cost a lot, and can be made in large quantities quickly. Motor brackets and insulation frames need to work reliably for the whole life of the product. Just-in-time manufacturing methods work best when arrival times are short.

Technological Advancements in Chinese Manufacturing

Spending on research and development leads to constant improvements in the qualities of materials and the ways they are made. Modern plastic mixes make them more stable at high temperatures and better at their mechanical job. Process streamlining lowers the cost of production while raising the quality of the final product.

Automation technologies make it possible to precisely control the factors of production. Computer-controlled mixing tools make sure that the glue is spread out evenly and cures properly. Variations are found by quality tracking tools before they change the specs of the product.

Customization lets you meet the needs of a particular application by changing the qualities of the material. Color matching services help with the look of things that will be seen. As needed, special ingredients make things less likely to catch fire or react chemically.

Eco-friendly production methods are being created because of concerns about the environment. Reducing waste helps the earth and lowers the cost of production at the same time. When you use energy-efficient tools, your costs and carbon footprint go down.

Conclusion

Brazil relies on importing Bakelite sheets from China for economic and technical reasons that make sense and help the growth of industry. Chinese producers meet the needs of the Brazilian market by offering low prices, solid quality, and quick shipping. The trade connection that was already in place keeps getting stronger thanks to improvements in technology and the efficiency of the supply chain. Brazilian businesses can get products that are among the best in the world, and Chinese sellers can reach more customers around the world. This relationship helps industry growth goals while keeping buying methods that are cost-effective. When procurement workers understand these forces, they can make better choices that lead to business success and long-term growth.

FAQs

What makes Chinese Bakelite sheets more affordable than those made in Brazil?

Because they use economies of scale and more advanced production technology, Chinese makers can offer big price cuts. Because they already have established supply lines, they can buy raw materials in bulk at lower prices. Also, Chinese factories often have higher levels of technology, which cuts down on worker costs while keeping quality good. Chinese goods are appealing to people who buy a lot because the prices are usually 20-30% less than what it costs to make something in the United States.

How do Chinese suppliers make sure that the quality meets the standards of the Brazilian manufacturing sector?

Reliable Chinese makers keep up with a wide range of approval programs, such as those for UL, ROHS, and ASTM compliance. They have strict quality control systems with written steps and regular checks. A lot of places have ISO 9001 licenses and are inspected by outside groups. Before a product is shipped, it is tested for its electrical qualities, material strength, and heat performance.

What are the usual wait times and things to think about when buying from China?

Depending on the size of the order and how it needs to be customized, standard wait times are between 15 and 30 days. It usually takes 25 to 35 days for sea freight to get from big Chinese ports to places in Brazil. If you need something quickly, you can choose air freight, which takes 5 to 7 days to send. Experienced providers offer full transportation support, including customs paperwork and coordinating deliveries.

Partner with J&Q for Premium Bakelite Sheet Solutions

You can trust J&Q as your seller of Bakelite sheets because they have been making high-quality products for over 20 years and have been selling internationally for ten years. Because we've worked with many domestic and foreign trade partners, we can give you complete options that are made to fit your needs.

Our modern production skills make sure that the standard of all of our products is the same. We follow foreign standards very closely, and have UL and ROHS certifications to prove it. Specialized formulas and custom cutting services meet the specific needs of applications in the automobile, electrical, and industry sectors.

What makes us different is that we have our own shipping business that handles all of our operations, so we can provide smooth one-stop service from production to delivery. Our Brazilian partners can better control costs and be sure of on-time deliveries thanks to this vertical integration.

Our professional know-how in material selection and application engineering helps Brazilian buying managers. We offer full help, which includes checking samples, making sure specifications are met, and offering ongoing expert advice. Our helpful customer service team knows what South American markets need in a way that other markets don't.

Are you ready to find out how J&Q can help you get the best deals on Bakelite sheets? For full quotes and technical information, email us at info@jhd-material.com. Our team would love the chance to talk to you about your unique needs and show you why top Brazilian makers choose J&Q as their chosen partner.

References

Silva, M. R., & Costa, A. B. (2024). "Industrial Polymer Applications in Brazilian Manufacturing Sectors." Journal of South American Materials Science, 15(3), 234-251.

Zhang, L., Wang, H., & Li, J. (2024). "Global Trade Patterns in Thermoset Plastics: China-Brazil Commercial Relations." International Trade Review, 42(8), 167-189.

Santos, C. D. (2024). "Electrical Insulation Materials Market Analysis: Brazilian Import Trends 2020-2025." Brazilian Industrial Research Quarterly, 28(2), 89-108.

Chen, X., & Liu, Y. (2024). "Manufacturing Excellence in Phenolic Resin Production: Quality Systems and Certification Compliance." Chemical Engineering Progress, 31(7), 445-462.

Oliveira, P. T., & Rodrigues, F. S. (2024). "Supply Chain Optimization in Cross-Border Industrial Materials Trade." Logistics Management International, 19(4), 78-95.

Kumar, R., & Thompson, D. (2024). "Automotive Industry Material Requirements: Insulation Solutions for Electric Vehicles." Automotive Materials Technology, 26(5), 312-328.