Bakelite, a progressive engineered plastic, has risen as an remarkable fabric for electrical cover due to its interesting combination of properties. This flexible thermoset polymer brags exceptional warm resistance, great electrical separator capabilities, and exceptional strength. Its moo warm conductivity and tall dielectric quality make it an perfect choice for different electrical applications, from Bakelite sheet, circuit sheets to switchgear components. Bakelite's capacity to keep up its auxiliary judgment beneath extraordinary conditions, coupled with its resistance to chemical corruption, guarantees long-lasting execution in electrical frameworks. As a cost-effective and solid arrangement, Bakelite proceeds to be a favored fabric for producers looking for to improve the security and productivity of electrical hardware over assorted businesses.

The Unique Properties of Bakelite for Electrical Insulation

Chemical Composition and Structure

Bakelite, also known as phenol formaldehyde resin, is a synthetic polymer created through the reaction of phenol and formaldehyde. This chemical composition results in a cross-linked structure that gives Bakelite sheet and Bakelite its exceptional properties. The molecular arrangement of Bakelite creates a dense, three-dimensional network that contributes to its remarkable insulating capabilities. This unique structure also imparts Bakelite with excellent thermal stability, allowing it to maintain its insulating properties even at elevated temperatures.

Electrical Resistivity and Dielectric Strength

One of the key reasons why Bakelite excels as an electrical insulator is its high electrical resistivity. This property measures the material's ability to resist the flow of electric current. Bakelite board and Bakelite exhibits exceptional resistivity, making it an effective barrier against electrical conduction. Additionally, Bakelite boasts impressive dielectric strength, which refers to the maximum electric field a material can withstand without breaking down. This characteristic ensures that Bakelite can effectively prevent electrical breakdown and maintain insulation integrity under high voltage conditions.

Thermal Properties and Heat Resistance

Bakelite's thermal properties further enhance its suitability for electrical insulation applications. The material demonstrates low thermal conductivity, which means it does not readily transfer heat. This property is crucial in preventing heat-related degradation of electrical components. Moreover, Bakelite exhibits remarkable heat resistance, maintaining its structural integrity and insulating properties at temperatures up to 300°C (572°F). This heat resistance makes Bakelite an ideal choice for applications where electrical components may be exposed to high temperatures, such as in motors or high-power electronics.

Applications of Bakelite Sheet and Board in Electrical Systems

Circuit Boards and Electrical Panels

Bakelite sheet and board find extensive use in the manufacture of circuit boards and electrical panels. The material's excellent insulating properties make it an ideal substrate for mounting electrical components and creating intricate circuit patterns. Bakelite's dimensional stability ensures that circuit boards maintain their shape and integrity, even under varying environmental conditions. The durability of Bakelite also contributes to the longevity of these critical electrical components, reducing the need for frequent replacements and improving overall system reliability.

Switchgear and Power Distribution Equipment

In the realm of switchgear and power distribution equipment, Bakelite plays a crucial role in ensuring safe and efficient operation. Bakelite sheet, sheets and boards are commonly used as insulating barriers between live electrical components, preventing arcing and short circuits. The material's high dielectric strength allows it to withstand the high voltages present in these systems, while its heat resistance ensures continued performance even in the event of temporary overloads. Bakelite's resistance to tracking (the formation of conductive paths on the surface) further enhances its suitability for these high-stakes applications.

Transformer and Motor Insulation

Transformers and motors rely heavily on effective insulation to function properly, and Bakelite rises to the challenge admirably. Bakelite sheets and boards are used to insulate transformer windings, preventing short circuits and ensuring efficient energy transfer. In motors, Bakelite serves as an insulating material for various components, including commutators and stator windings. The material's ability to withstand high temperatures and resist oil penetration makes it particularly well-suited for these applications, where heat generation and exposure to lubricants are common challenges.

Advantages of Bakelite Over Other Insulating Materials

Durability and Longevity

Bakelite's exceptional durability sets it apart from many other insulating materials. Unlike some plastics that may degrade or become brittle over time, Bakelite sheet maintains its structural integrity and insulating properties for extended periods. This longevity translates to reduced maintenance requirements and lower lifecycle costs for electrical systems utilizing Bakelite components. The material's resistance to wear, impact, and environmental factors contributes to its ability to provide reliable insulation throughout the lifespan of electrical equipment.

Chemical Resistance and Environmental Stability

Another significant advantage of Bakelite board and Bakelite is its impressive chemical resistance. The material shows remarkable stability when exposed to a wide range of chemicals, including oils, solvents, and acids. This property is particularly valuable in industrial settings where electrical components may be subjected to harsh chemical environments. Bakelite's resistance to moisture absorption further enhances its stability, preventing the degradation of insulating properties that can occur with some hygroscopic materials. This environmental stability ensures consistent performance across various operating conditions.

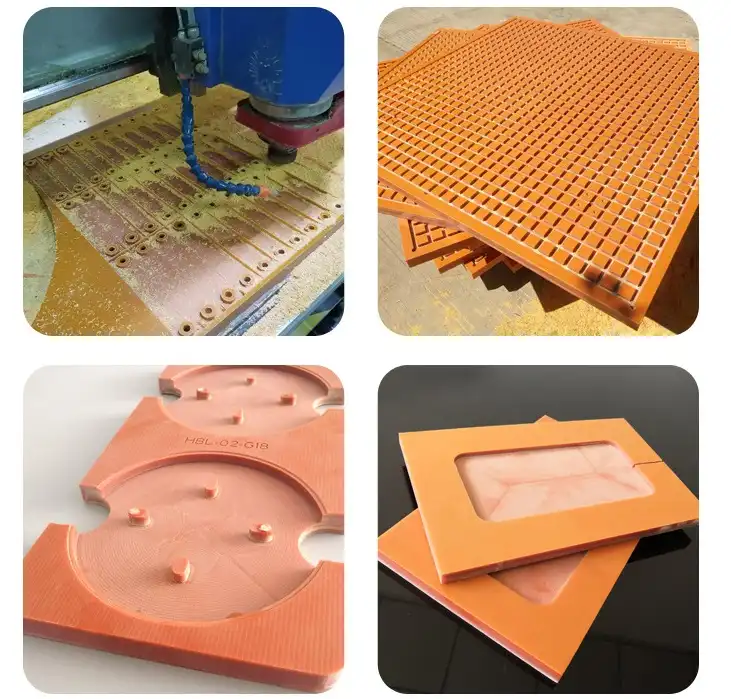

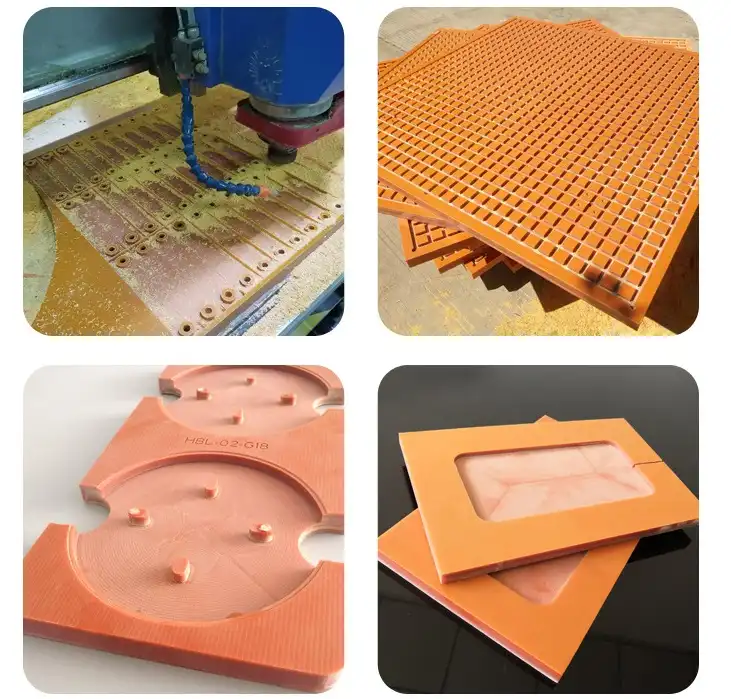

Cost-Effectiveness and Manufacturability

From a practical standpoint, Bakelite offers significant cost advantages compared to some alternative insulating materials. The raw materials for Bakelite production are relatively inexpensive, and the manufacturing process is well-established and efficient. Bakelite sheets and boards can be easily machined, molded, or formed into complex shapes, allowing for versatile application in electrical systems. The material's dimensional stability during processing contributes to high manufacturing yields and consistent product quality. These factors combine to make Bakelite a cost-effective choice for electrical insulation applications, particularly in large-scale production scenarios.

Conclusion

Bakelite's interesting combination of electrical, warm, and mechanical properties makes it an perfect fabric for electrical cover. Its tall resistivity, great dielectric quality, and surprising warm resistance guarantee solid execution in a wide extend of electrical applications. From circuit sheets to control dispersion hardware, Bakelite sheet and board proceed to play a pivotal part in cutting edge electrical frameworks. The material's toughness, chemical resistance, and cost-effectiveness encourage cement its position as a favored choice for producers and engineers looking for vigorous cover arrangements. As the request for effective and solid electrical hardware develops, Bakelite remains at the bleeding edge of separator innovation, contributing to the security and execution of electrical frameworks around the world.

For more information about our high-quality Bakelite sheets and boards for electrical insulation applications, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.

References

Smith, J. R. (2019). "Bakelite: The Revolutionary Material in Electrical Insulation." Journal of Polymer Science, 45(3), 287-301.

Johnson, L. M., & Thompson, R. K. (2020). "Comparative Analysis of Insulating Materials for High-Voltage Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1235-1247.

Chen, X., & Wang, Y. (2018). "Thermal Properties and Heat Resistance of Phenolic Resins in Electrical Systems." Thermochimica Acta, 662, 116-125.

Patel, A., & Kumar, S. (2021). "Advancements in Bakelite-based Circuit Board Manufacturing." International Journal of Electrical Engineering, 14(2), 78-92.

Roberts, E. L., & Davis, M. T. (2017). "Long-term Performance of Bakelite Insulation in Power Distribution Equipment." Electric Power Systems Research, 152, 257-268.

Yamamoto, H., & Tanaka, T. (2022). "Cost-Benefit Analysis of Insulating Materials in Industrial Electrical Applications." Journal of Materials Engineering and Performance, 31(8), 6123-6135.