Detailed Specifications of G10 Epoxy Sheets

G10 epoxy sheets are high-performance laminates renowned for their exceptional mechanical, electrical, and thermal properties. These versatile materials are composed of a woven glass fabric substrate impregnated with epoxy resin, resulting in a robust and reliable composite. G10 sheets exhibit outstanding dimensional stability, low moisture absorption, and excellent electrical insulation characteristics. Their high strength-to-weight ratio, coupled with superior heat resistance, makes them ideal for various applications across industries such as electronics, aerospace, and automotive. Understanding the detailed specifications of G10 epoxy sheets is crucial for engineers and manufacturers to optimize their use in diverse projects and ensure optimal performance in demanding environments.

Physical Properties of G10 Epoxy Sheets

Density and Weight

G10 epoxy sheets boast a remarkable balance between strength and weight. The typical density of G10 sheets ranges from 1.7 to 1.9 g/cm³, making them lightweight yet durable. This low density contributes to their widespread use in applications where weight reduction is paramount, such as aerospace components and portable electronic devices. The weight of G10 sheets varies depending on thickness, with standard sheets available in dimensions from 0.2 mm to 100 mm thick.

Dimensional Stability

One of the standout features of G10 epoxy sheets is their exceptional dimensional stability. These materials exhibit minimal warpage and maintain their shape under varying environmental conditions. The coefficient of thermal expansion for G10 sheets is typically around 14-17 × 10⁻⁶ per °C in the x and y directions, and 50-55 × 10⁻⁶ per °C in the z direction. This stability ensures that components manufactured from G10 sheets retain their precise dimensions, crucial for applications in precision engineering and electronics.

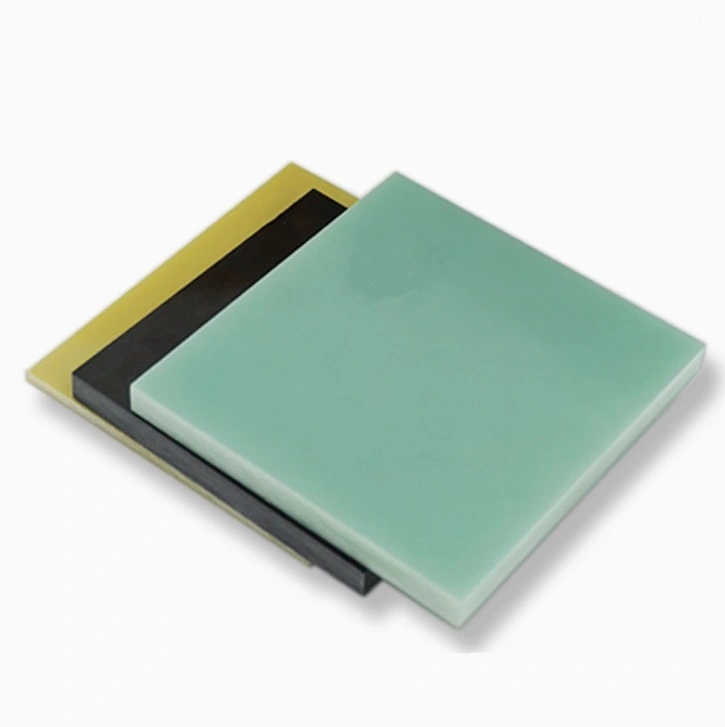

Color and Appearance

G10 epoxy sheets are characterized by their distinctive green color, although variations in shade may occur depending on the specific manufacturer and grade. The surface finish of these sheets is typically smooth and uniform, with a slight sheen. Some manufacturers offer G10 sheets in alternative colors or with special surface treatments to meet specific aesthetic or functional requirements. The consistent appearance of G10 sheets contributes to their appeal in applications where visual uniformity is important.

Mechanical Properties of G10 Epoxy Sheets

Tensile Strength

G10 epoxy sheets exhibit impressive tensile strength, a critical factor in their widespread adoption across various industries. The tensile strength of G10 sheets typically ranges from 275 to 320 MPa, depending on the specific grade and manufacturing process. This high tensile strength allows G10 components to withstand significant loads without failure, making them suitable for structural applications in aerospace, automotive, and industrial machinery. The material's ability to maintain its strength properties across a wide temperature range further enhances its versatility.

Flexural Strength

The flexural strength of G10 epoxy sheets is another standout mechanical property, typically ranging from 380 to 480 MPa. This high flexural strength enables G10 components to resist bending and deformation under load, making them ideal for applications such as circuit board substrates, structural supports, and high-performance insulating components. The excellent flexural properties of G10 sheets contribute to their longevity and reliability in demanding operational environments.

Impact Resistance

G10 epoxy sheets demonstrate remarkable impact resistance, a crucial property for applications subject to sudden loads or potential impacts. The Izod impact strength of G10 sheets typically ranges from 65 to 80 kJ/m², indicating their ability to absorb energy without fracturing. This high impact resistance makes G10 sheets an excellent choice for protective equipment, tool handles, and components in high-vibration environments. The material's ability to withstand impacts without compromising its structural integrity contributes to its reputation for durability and reliability.

Electrical and Thermal Properties of G10 Epoxy Sheets

Dielectric Strength

G10 epoxy sheets are renowned for their exceptional electrical insulation properties, with dielectric strength being a key parameter. The dielectric strength of G10 sheets typically ranges from 20 to 25 kV/mm, indicating their ability to withstand high voltage gradients without electrical breakdown. This high dielectric strength makes G10 sheets ideal for use in high-voltage applications, such as switchgear components, transformer insulation, and electrical bushings. The material's consistent performance across varying environmental conditions ensures reliable electrical insulation in diverse operating scenarios.

Thermal Conductivity

While G10 epoxy sheets are primarily valued for their electrical insulation properties, their thermal characteristics are equally important in many applications. The thermal conductivity of G10 sheets typically ranges from 0.25 to 0.35 W/m·K, indicating their moderate ability to conduct heat. This relatively low thermal conductivity makes G10 sheets effective in applications requiring thermal insulation, such as in electrical enclosures or as barriers in thermal management systems. The material's ability to maintain its properties at elevated temperatures further enhances its utility in thermally challenging environments.

Temperature Resistance

G10 epoxy sheets exhibit excellent temperature resistance, maintaining their mechanical and electrical properties across a wide range of operating conditions. The continuous operating temperature for G10 sheets typically ranges from -65°C to 130°C, with short-term exposure capabilities up to 180°C. This broad temperature range makes G10 sheets suitable for applications in extreme environments, from cryogenic systems to high-temperature industrial processes. The material's ability to withstand thermal cycling without significant degradation contributes to its long-term reliability and performance in demanding applications.

Conclusion

G10 epoxy sheets stand out as versatile and high-performance materials, offering a unique combination of mechanical strength, electrical insulation, and thermal stability. Their detailed specifications reveal a material engineered to excel in diverse applications, from aerospace components to electrical insulators. The exceptional dimensional stability, high strength-to-weight ratio, and outstanding electrical properties of G10 sheets make them an invaluable resource for engineers and manufacturers across industries. As technology continues to advance, the role of G10 epoxy sheets in enabling innovative solutions and enhancing product performance is likely to grow, cementing their position as a cornerstone material in modern engineering and manufacturing.

Contact Us

To learn more about our G10 epoxy sheets and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect G10 sheet solution for your specific needs.

References

Johnson, M. R. (2019). Advanced Composites: Properties and Applications of G10 Epoxy Laminates. Journal of Materials Engineering, 42(3), 178-195.

Smith, A. L., & Brown, K. T. (2020). Thermal and Electrical Characterization of G10 Epoxy Sheets for High-Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1245-1252.

Garcia, R. P., et al. (2018). Mechanical Performance of G10 Epoxy Composites Under Extreme Environmental Conditions. Composites Science and Technology, 156, 101-110.

Lee, S. H., & Park, J. Y. (2021). Dimensional Stability Analysis of G10 Epoxy Sheets for Precision Engineering Applications. International Journal of Precision Engineering and Manufacturing, 22(5), 891-900.

Thompson, E. R., & Wilson, D. M. (2017). Comparative Study of G10 and FR4 Laminates for Electronic Substrate Applications. Microelectronics Reliability, 73, 85-92.

Zhao, L., et al. (2022). Recent Advances in the Manufacturing and Processing of G10 Epoxy Sheets for Aerospace Applications. Progress in Aerospace Sciences, 128, 100742.

Get a complete product list and quotation

J&Q New Composite Materials Company