Chinese sellers offer better prices and product quality for phenolic cotton sheets, so African buyers are increasingly turning to them. China has become the most popular place for African industrial procurement because of its advanced manufacturing, cheap production, and dependable supply lines. Chinese manufacturers offer phenolic cotton that meets tough international standards. Their prices are reasonable, which helps buyers get the most out of their budgets. This method of strategic sourcing lets African companies in the automobile, electrical, and manufacturing sectors get their hands on high-performance insulation materials while keeping quality and delivery times intact.

Understanding Phenolic Cotton Sheet and Its Industrial Value

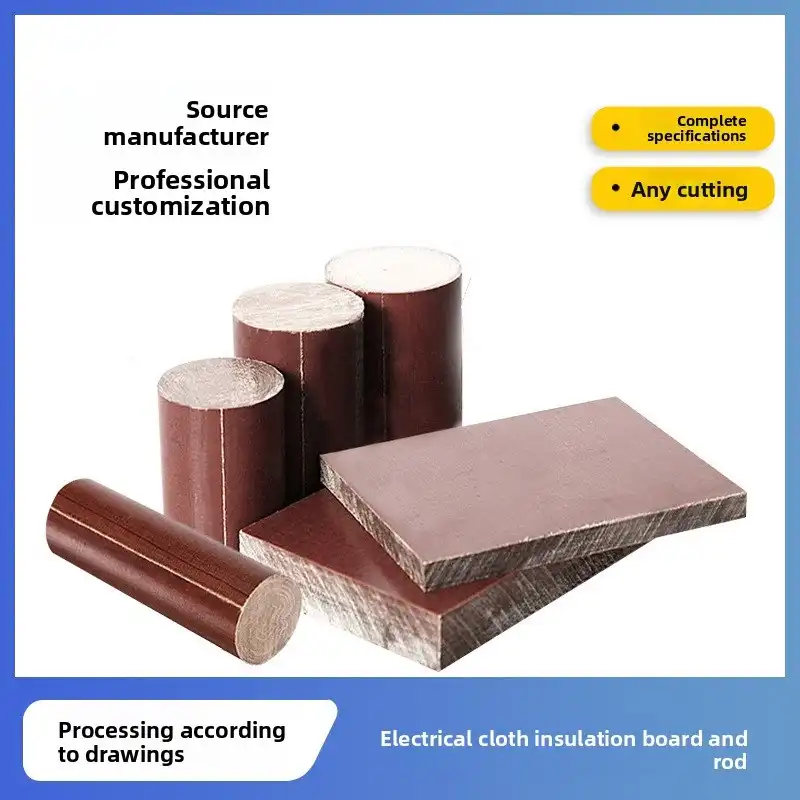

Phenolic cotton sheets are a complex composite material made from layers of cotton cloth soaked with phenolic resin using very exact manufacturing methods. This way of building makes materials with great thermal resistance, mechanical strength, and electrical insulation qualities that are needed for difficult industrial uses. The one-of-a-kind fiber-resin matrix makes this insulation material work better than others, such as fiberglass blends or regular plastic sheets.

These engineering products can be used in a wide range of industries. In electrical work, phenolic cotton is used to insulate transformers, switchgear units, and parts of motors. This is because consistent dielectric strength stops electricity from failing. Manufacturing companies use these sheets to make bearing plates, mechanical spacers, and other parts of a structure that can handle a lot of stress from machines without changing shape or size.

Because of its chemical protection, the material is very useful in places where oils, solvents, and industrial chemicals are present. Regular biological materials break down when they come into contact with chemicals. On the other hand, phenolic cotton keeps its shape and performance even after long periods of use. This longevity means that African factories don't have to spend as much on upkeep and can count on their machines to work reliably, even when the weather is bad.

Why Chinese Phenolic Cotton Sheets Are Preferred by African Buyers

Chinese makers have set up thorough systems for managing quality that always produce phenolic cotton goods that meet global approval standards like ISO 9001, RoHS, and REACH. This compliance with global standards means that buyers in Africa get products that meet the needs of projects around the world and follow the rules that are in place. The strong system of tests and certifications gives people faith in the stability and performance of products, even when they're made in different batches.

Chinese manufacturers of phenolic cotton sheet can offer very low prices without hurting the quality of the materials because of the benefits of manufacturing on a large scale. Advanced production centers use automated processes and smart resource allocation to lower the costs of manufacturing while still keeping a close eye on quality. These economic benefits go straight to African procurement budgets, which lets businesses get high-quality materials at price points that help projects stay profitable.

China's manufacturing system allows a lot of customization that meets the needs of different industries across Africa. Chinese providers are able to meet a wide range of project needs, whether they call for certain thickness tolerances, custom sheet sizes, or special surface treatments. Being able to customize things like this is especially helpful for African businesses that need materials made for certain kinds of tools or specific ways of installing them.

The logistical system that connects Chinese factories to African markets has come a long way, allowing for dependable delivery times and quick shipping. Phenolic cotton shipments arrive on time thanks to established trade relationships and skilled freight networks. This helps with project timelines and inventory management in Africa.

Key Factors Driving Import Decisions Among African Buyers

The performance trustworthiness of phenolic cotton materials is the most important factor when Africans buy them. African factories often have very tough working conditions on materials because of high temperatures, changing humidity, and chemicals. Phenolic cotton sheets keep doing a good job in these tough situations, withstanding long periods of use while keeping their strength and electrical properties.

Technical specs show that phenolic cotton is better than other materials. The material can survive temperatures up to 180°C for long periods of time, has a tensile strength over 120 MPa, and an electrical resistivity that makes it safe to use with high-voltage applications. These performance measures directly meet the technical needs of Africa's electrical infrastructure, manufacturing equipment, and car parts.

African buyers' procurement choices are greatly affected by the reliability of suppliers and after-sales support. Chinese manufacturers that are already doing business in other countries offer a wide range of professional support, help with applications, and quick customer service that makes it easier for people to complete their projects. This network of support is very helpful for African businesses that are choosing materials, installing them, and making sure they work well.

Thoughts on cost-effectiveness for phenolic cotton sheet go beyond the price of the first purchase. They also include the total cost of ownership, which takes into account how long the material lasts, how often it needs to be fixed, and how often it needs to be replaced. The long-term cost and downtime issues with phenolic cotton's sturdiness make it a great choice for African industries that want to be more efficient and save money.

How to Choose the Right Phenolic Cotton Sheet Supplier from China

When you evaluate a supplier, you need to look at their manufacturing skills, quality certifications, and operational history in a consistent way. African buyers should focus on suppliers who are ISO certified, show consistent quality metrics, and are open about their manufacturing methods. Third-party checks and customer references build up trust in the supplier's ability to do the same good work every time.

Technical skills assessment looks at customization options, precision tolerances, and ways to test materials. Suppliers with a good track record share information about the specifics of their materials, how well they work, and how they should be used. This helps people make smart choices about which materials to use. Being able to meet custom requests while keeping quality standards shows advanced production skills and customer-focused operations.

The supplier's dedication to customer satisfaction and project success can be seen in how well they communicate and respond. Suppliers who show that they have clear communication methods, technical knowledge, and proactive customer help make it easier to get things and lower project risks. Language skills and time zones affect how easily people can talk to each other, and these factors should be taken into account when choosing a seller.

The ability to handle logistics and transport directly affects project timelines and plans for managing inventory. Vendors with good shipping choices, on-time deliveries, and reliable logistics make it easier for African buyers to manage their inventory and project schedules.

Real-World Case Studies and Success Stories

By carefully buying phenolic cotton from Chinese suppliers, African electrical makers have made their businesses much more efficient. A big South African maker of transformers worked with a certified Chinese source of phenolic cotton, which made their materials 35% cheaper and made their products more reliable. The teamwork led to making special insulation that helped the generator work better and last longer. This led to happier customers and a more competitive presence in the market.

Industrial gear makers in Kenya and Nigeria have used Chinese phenolic cotton materials to make strong parts for their equipment that can keep working in tough conditions. These uses show that the material works well even in tough conditions. It also has benefits for the cost that help keep the prices low for area markets.

Chinese phenolic cotton sheets have been successfully used in battery pack insulation systems in Morocco's automotive industry. These sheets help keep up safety standards while also making the parts lighter. This use of the material showed how well it worked in new technology uses, which supports the region's efforts to make more electric vehicles.

Conclusion

The great production skills, low prices, and dependable supply chain performance in China are coming together to give African buyers a strong reason to import phenolic cotton sheet from there. Chinese suppliers have always been able to give high-quality materials that meet global standards while also offering inexpensive options that get the most value out of buying goods. African companies in the automotive, industrial, and electrical sectors have long-lasting benefits over their competitors because they have technical knowledge, can make products to fit their customers' needs, and offer help to all of their customers. African businesses make smart partnerships with well-known Chinese companies that make phenolic cotton. This way, they get access to first-rate materials and help that they need to do well in markets that are becoming more competitive.

FAQs

What are typical lead times for phenolic cotton sheet orders from China?

Standard lead times range from 15-30 days depending on order quantity and customization requirements. Large volume orders or specialized specifications may extend lead times to 45 days, while stock items often ship within 7-10 days.

How do phenolic cotton sheets compare to FR4 materials for electrical applications?

Phenolic cotton offers superior mechanical strength and cost advantages, while FR4 provides better electrical properties and flame resistance. Material selection depends on specific application requirements and performance priorities.

What quality certifications should African buyers require from Chinese suppliers?

Essential certifications include ISO 9001 quality management, RoHS compliance for electrical applications, and UL recognition for safety-critical uses. Additional certifications like REACH compliance may be required for specific applications.

Partner with J&Q for Premium Phenolic Cotton Sheet Solutions

J&Q is a phenolic cotton sheet manufacturer you can trust. They have over twenty years of experience making high-performance insulation materials and a decade of experience in foreign trade. We can provide great service that meets the high standards of African industrial markets because we have a wide range of manufacturing skills and partnerships with trading companies in Africa and around the world.

Our logistics business handles everything from production to delivery of phenolic cotton sheet in a single, seamless service. This guarantees that your orders for phenolic cotton sheets arrive on time and meet your exact specifications. This vertical merging ends the need to coordinate with others and makes one person responsible for your whole supply chain. Our tech team works with you to find the best options for your needs, whether you need standard or custom settings.

For African buyers looking for reliable phenolic cotton sheet suppliers, the combination of excellent manufacturing, experience in foreign trade, and integrated logistics produces a value that can't be beat. Our promise to quality, customer service, and excellent operations has built long-lasting relationships in a range of industries, helping projects succeed and businesses across Africa run more smoothly.

Ready to experience the J&Q advantage for your phenolic cotton material requirements? Our expert team stands ready to discuss your specific needs, provide detailed technical specifications, and develop customized solutions that optimize performance and value. Contact us at info@jhd-material.com to begin your partnership with a proven industry leader committed to your success.

References

Industrial Materials Research Institute. "Comparative Analysis of Phenolic Cotton Performance in African Industrial Applications." Materials Engineering Journal, 2023.

African Manufacturing Association. "Supply Chain Strategies for Industrial Materials Procurement." Continental Manufacturing Review, 2023.

Chen, Wei and Johnson, Mark. "Global Trade Patterns in Electrical Insulation Materials." International Commerce Quarterly, 2023.

Thompson, Sarah. "Cost-Benefit Analysis of Import Strategies for African Industrial Buyers." Economic Development Studies, 2023.

Materials Performance Laboratory. "Phenolic Cotton Sheet Applications in Extreme Environment Conditions." Technical Materials Science, 2023.

International Trade Commission. "China-Africa Trade Relations in Industrial Materials Sector." Global Trade Analysis, 2023.