Russian procurement professionals increasingly turn to Chinese manufacturers for FR4 epoxy sheet sourcing due to China's advanced manufacturing capabilities, competitive pricing, and reliable supply chains. There are well-established industrial hubs in Guangdong, Jiangsu, Hebei and Zhejiang provinces that are the main sources of supplies. These are places where specialized makers give a wide range of products, from standard PCB-grade laminates to custom insulation solutions. There are a lot of authorized providers in these areas. They follow international quality standards and offer flexible order sizes and technical support services that are suited to the needs of the Russian market.

Understanding FR4 Epoxy Sheet and Its Key Properties

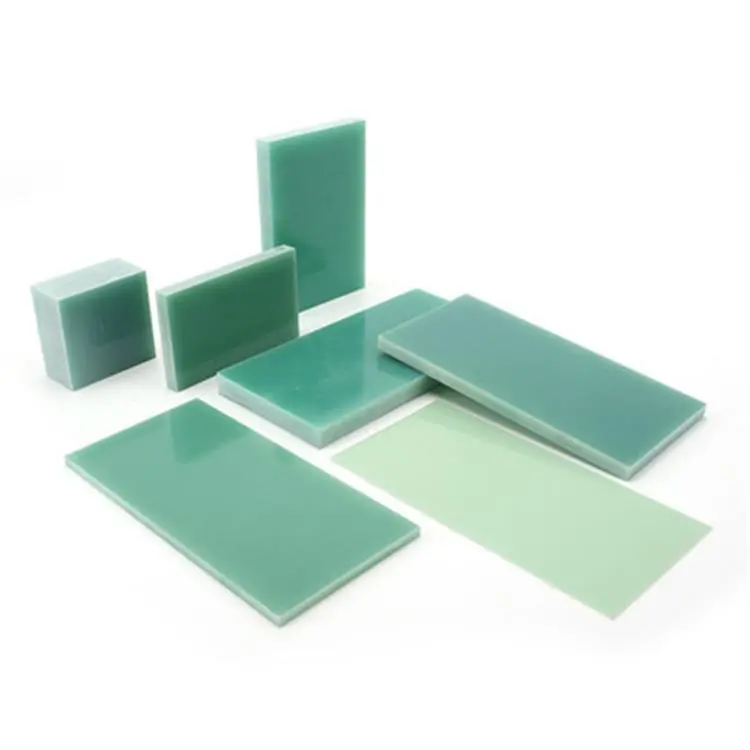

Many industrial uses can benefit from FR4 epoxy sheet, which is a glass-reinforced epoxy material that works very well. Woven fiberglass cloth and epoxy glue are mixed together to make this composite material. It is a flexible base that is known for its excellent electrical protection, mechanical strength, and heat stability. The label "FR4" on a material means that it is flame-resistant and meets UL94 V-0 standards, so it can be used in safety-critical situations.

Some of the scientific specs for good epoxy laminates are dielectric constant values between 4.2 and 4.8 at 1MHz frequency, glass transition temperatures above 130°C, and bending strength ratings above 415 MPa. These factors have a direct effect on how well things work in situations like printed circuit board bases, electrical protection components, and motor insulation systems. The material's ability to keep its shape even when temperatures change makes it stable for use in harsh industrial settings.

When compared to other materials, such as phenolic sheets or ceramic surfaces, FR4 epoxy laminates are more cost-effective without sacrificing important performance features. Because these sheets can be cut with a CNC machine, complicated shapes can be made with great accuracy, and the material's uniform width tolerances support high-precision industrial processes. Russian tech teams really like these qualities because they can be used to make electronics and distribute power.

Why China Is the Preferred Source for FR4 Epoxy Sheets Among Russian Buyers?

China is the world's biggest market for insulation sheets because it has decades of experience making things and improving technology. The country can make more than 2 million tons of glass-fiber reinforced plastics every year, and it has special factories that only make high-quality electrical insulation materials. Because China has such a large manufacturing system, their prices can stay low while still making sure that their products are always available and of good quality.

Russian buyers are drawn to Chinese products because they are affordable and meet all certification requirements. For example, top Chinese makers keep their ISO 9001, RoHS, and UL licenses. These approvals make sure that the products being sent to Russia meet the safety and environmental standards set by the Russian government. Advanced quality control systems are used in factories. These systems include automatic testing tools for checking dielectric strength and temperature analysis.

When deciding where to source something, logistics are very important. China and Russia already have established trade routes. These include rail links along the Trans-Siberian region and ships through ports in the Pacific. These routes offer safe delivery options with short travel times. A lot of Chinese sellers offer full transportation support, such as customs paperwork and freight management services, which makes it easier for Russian buyers to buy things.

One big benefit is that Chinese makers are able to adapt to specific needs, which is another big plus. To meet the needs of unique applications, suppliers are happy to offer non-standard sizes, custom cutting services, and specialized surface treatments. Because they are flexible and don't have high minimum order amounts, Chinese suppliers are great for both large-scale production and one-off projects.

How Russian Buyers Can Identify and Evaluate Trusted FR4 Epoxy Sheet Suppliers in China?

Finding a good provider starts with making sure that the producing skills and quality control systems are checked out carefully. Reliable Chinese providers keep a lot of paperwork, such as licenses for materials, information about their production capacity, and quality control methods. To figure out how reliable a seller is and how much they can make, buyers should ask for full company descriptions, photos of the facilities, and lists of customer references.

Technical competence is one of the most important things that is looked at when judging a provider. This can be seen in how well they can provide thorough material specs, testing results, and application advice. Manufacturers who have been around for a while usually provide a lot of information about their products, such as temperature analysis data, mechanical property charts, and electrical features proof. This technical help feature shows how knowledgeable and dedicated the seller is to customer service.

Effective communication has a big effect on how well buying relationships work. Leading Chinese sellers hire customer service reps who can speak more than one language and keep expert staff with experience working in other countries. Quick responses to questions, clear quote forms, and detailed delivery plans are all signs of professional service standards that make business deals go more smoothly.

When analyzing possible sellers, these are the most important things to keep in mind:

Verification of Certification: Check to see if the FR4 epoxy sheet has the latest ISO 9001 quality management approval, RoHS compliance paperwork, and UL listed status. Ask for pictures of awards and check their accuracy with the organizations that issued them. These certificates show that the company is committed to meeting foreign quality standards and following the rules that are necessary for the Russian market to accept them.

Evaluation of Production Capacity: Look at the industrial scale by looking at the size of the building, the list of equipment, and the amount of product that is made each month. Having enough capacity guarantees a steady supply and the ability to handle different order amounts. Large buildings usually mean that the business has been around for a while and has a good track record.

Quality Control Systems: Go over the testing methods, review rules, and best practices for quality documents. Advanced providers use computerized testing tools, statistical process control, and full material tracking systems to make sure that the standard of their products always stays high and they work as expected.

Customer Service Infrastructure: Look at the company's expert help, order management, and service after the sale. Responding to customer needs shows that a business is skilled and dedicated to building long-term business relationships, which is necessary for ongoing buying partnerships to work.

With these evaluation factors, Russian buyers can find sellers who can meet their unique application needs for quality, service, and price with consistency.

Practical Tips for Procurement and Risk Mitigation When Buying FR4 Epoxy Sheets from China

To reduce risk effectively, you need to have detailed buy deals that spell out what materials are needed, how they should be made, and when they should be delivered. Thickness limits, dielectric strength values, heat performance factors, and surface finish standards should all be part of the detailed technical specs. Clear paperwork stops confusion and gives you options if there are problems with the quality or arrival times.

A very important part of qualifying a provider is evaluating samples. Ask for samples of the suggested materials so that they can be tested by someone else and the specs can be confirmed. Standardized test methods should be used for measuring electrical strength, temperature analysis, and dynamic properties. Before agreeing to big orders, this evaluation process makes sure that the material is suitable and that the seller can meet the needs.

Negotiating payment terms strikes a balance between transaction security and cash flow concerns. Suppliers who have been around for a while will usually accept letters of credit or recorded collections, which cover both parties. Don't pay in advance for the first order until the supplier's dependability has been shown by delivering samples successfully and checking the quality.

Third-party checking services are another way to make sure that large orders are of high quality. Before a package goes out, independent testing companies can check the material specs, quality of the packing, and correctness of the amount. This step of proof gives an unbiased confirmation that the order was followed correctly and helps avoid costly quality problems or transport mistakes.

Conclusion

Chinese sellers have become trusted partners for Russian buyers looking for high-quality FR4 epoxy sheets by offering low prices, full technical support, and well-established transportation networks. China is a good place to get electrical insulation products because they have advanced production skills, are certified by international organizations, and offer a range of open service options. To be successful in buying, you need to carefully evaluate suppliers, write down clear specifications, and handle relationships with them professionally. If Russian buyers take the time to qualify suppliers and build relationships with them, they can get world-class products while lowering the risks of buying and making sure the supply chain is reliable.

FAQs

What are the usual thicknesses that Chinese providers of FR4 epoxy sheets offer?

FR4 epoxy sheets from Chinese makers usually come in standard widths of 0.2mm to 25.4mm and popular sizes of 0.5mm, 1.0mm, 1.6mm, 2.0mm, and 3.2mm. You can ask for different thickness choices, and we can control the accuracy to within ±0.05mm for most requirements. This wide range can meet the needs of a wide range of applications, from thin PCB surfaces to thick structural insulation components.

What are the differences between Chinese FR4 epoxy sheet approvals and the European standards that Russia needs?

Some of the biggest Chinese companies have a lot of foreign certificates, such as the UL94 V-0 flame rating, RoHS compliance, and ISO 9001 quality management systems. These approvals are in line with the requirements for European CE marking and Russian GOST norms for materials used to insulate electrical appliances. Material test results usually have information on a material's dielectric strength, temperature index, and flammability that meets the needs of industrial uses.

What is the smallest amount of FR4 epoxy sheets that Russian buyers should be able to order from China?

Minimum order amounts depend on the seller and the goods, but for normal types, they are usually between 100 kg and 500 kg. For new buyers, established makers may be able to handle smaller initial orders, but for unique specs, higher minimums may be needed. A lot of sellers have open buying options that let buyers build relationships with them by getting small amounts at first before increasing the amount they produce.

J&Q: Your Trusted FR4 Epoxy Sheet Supplier with Comprehensive Solutions

J&Q is one of the best Chinese manufacturers because it has been making high-quality insulation materials for over 20 years and has been involved in foreign trade for over 10 years. Our manufacturing skills are very broad and cover all kinds of electrical insulation products. We are especially good at making FR4 epoxy sheets for tough industrial uses. Because we have worked in this field for so long, we know exactly what Russian buyers need and can give them answers that are made to fit their needs.

Our wide range of services goes beyond simple production and includes full control of the entire supply chain. Because we have our own logistics business, we can offer an all-in-one service that makes buying things easier and makes sure that deliveries happen on time. We have better control over quality, speed, and contact with customers throughout the whole order delivery process thanks to this vertical integration.

Our facilities have advanced testing tools for making sure the materials are correct, precise cutting services for unique sizes, and flexible production schedules to handle orders of different sizes. Our quality control methods make sure that we always meet foreign standards, such as those set by ISO 9001, RoHS, and UL. These certificates show that we are dedicated to providing materials that meet the exact needs of Russian industrial uses.

Long-term relationships with trading companies in both the United States and other countries have helped us learn more about the needs of the global market and what customers expect from customer service. As a result of this experience, Russian procurement experts can rely on quick technology help, clear communication methods, and reliable order delivery to meet their most important material needs. Are you ready to get FR4 epoxy sheets from professionals? You can email us at info@jhd-material.com to get thorough quotes and expert advice that is made to fit your needs.

References

International Trade Administration. "China's Advanced Materials Manufacturing Industry Report 2023." U.S. Department of Commerce.

Polymer Testing Institute. "Comparative Analysis of FR4 Epoxy Laminate Properties and Applications." Materials Science Quarterly, Vol. 45, 2023.

Sino-Russian Trade Council. "Industrial Materials Trade Flow Analysis: Electrical Insulation Products." Moscow Economic Review, 2023.

Chinese Chamber of Commerce. "Quality Standards and Certification Requirements for Exported Electrical Materials." Beijing Industrial Standards Publication, 2023.

Asian Manufacturing Association. "Supply Chain Optimization in Electrical Insulation Materials Procurement." Industrial Procurement Monthly, Issue 8, 2023.

International Electrical Safety Foundation. "Global Standards Comparison for Flame Retardant Laminate Materials." Technical Safety Review, Vol. 12, 2023.