Through specialized B2B platforms, direct factory partnerships, and trusted trading companies, established Chinese makers are the main source of 3240 epoxy sheet for buyers in Indonesia. China leads the market for electrical insulation materials around the world, with a wide range of products at low prices and quality control that meets global standards. The strategic sourcing method uses well-known supply chains, verified networks of suppliers, and thorough quality assurance processes to make sure that materials always work the same way in a wide range of industries.

Understanding 3240 Epoxy Sheet and Its Critical Role in Indonesian Industries

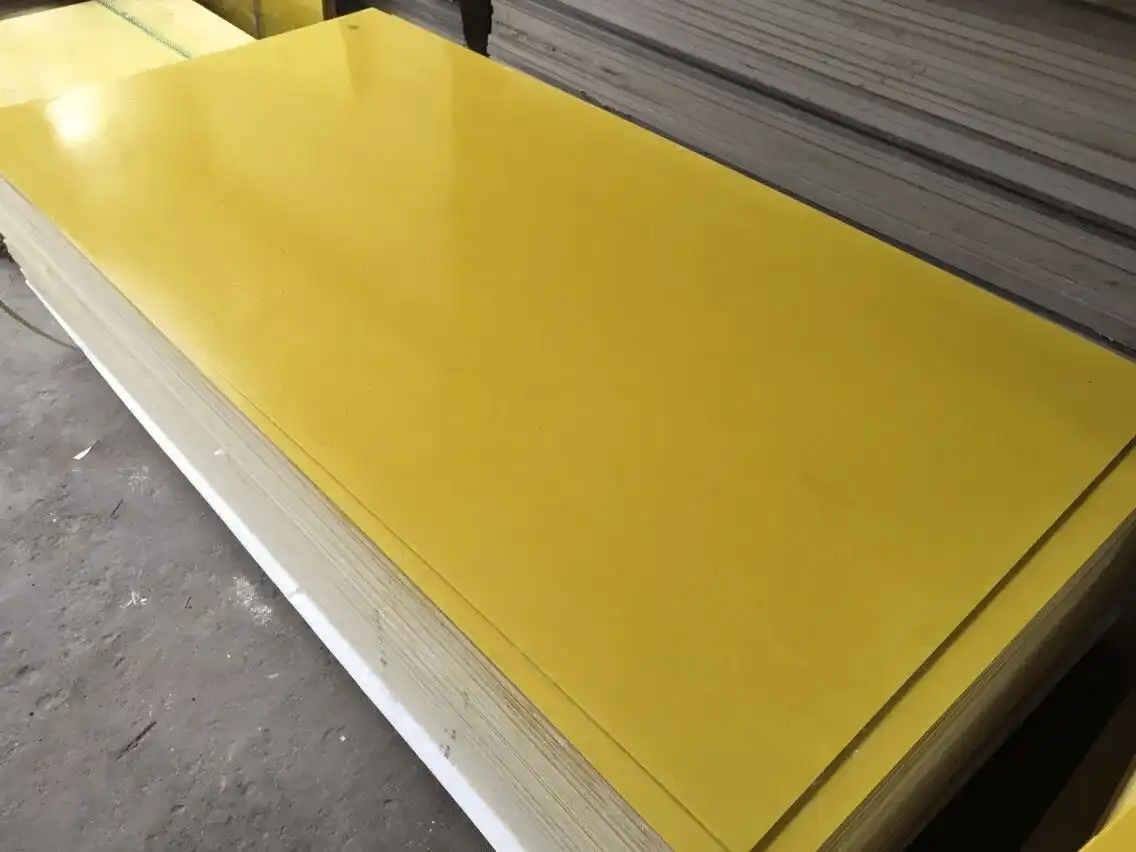

Indonesia's technology and manufacturing industries are growing, so they need high-performance insulation materials. Epoxy glass cloth laminates, especially the G11 grade, are important parts of electrical systems, tools, and precision equipment. These composite materials are made of woven glass fabric and epoxy resin systems. They have great mechanical strength and electrical qualities.

These insulation boards are used a lot by Indonesian electrical makers in switchgear assemblies, transformer parts, and motor housings. Because it has a dielectric strength of more than 16 kV/mm, it is very important for high-voltage uses. It can also handle temperatures up to 180°C and keep its shape, so it will work well in tough industrial settings.

These materials are especially important to Indonesia's car industry for use in electric vehicles as battery pack insulation and thermal barriers. Home appliance makers need uniform dimensional stability and good machinability for mass production. Power generation facilities need flame-resistant grades that meet international safety standards for important infrastructure.

Strategic Considerations for Indonesian Procurement Teams

Successful procurement strategies look at technical specs that fit the needs of the application. To make sure they pick the best material, Indonesian buyers look at a lot of different performance factors. Technical evaluation methods are based on temperature performance, chemical resistance, and mechanical strength.

When looking at epoxy glass materials such as 3240 epoxy sheet and other options like phenolic cotton laminates or FR4 substrates, procurement workers look at performance benefits and cost-effectiveness ratios. Epoxy glass cloth usually has better mechanical properties than paper-based phenolic materials and better chemical protection than standard FR4 grades.

Quality assurance methods are another important way to judge something. Indonesian businesses want their suppliers to have ISO 9001 certification, UL recognition, and RoHS compliance paperwork. These certifications make sure that products are always of high quality and that export-focused production companies follow the rules.

When thinking about supply chain dependability, you should look at production capacity, lead time, and logistics coordination. Well-known Chinese companies often have enough stock on hand to meet pressing delivery needs. They also let customers order different amounts to fit their changing production schedules.

Identifying Reliable Chinese Suppliers for Optimal Partnership

The process of choosing a provider needs a full review of their manufacturing skills, technical knowledge, and service quality standards. Indonesian procurement managers usually use a number of different factors to choose possible partners and build long-term strategic relationships.

Quality control systems, testing lab skills, and certifications for production facilities are all signs of great manufacturing. Top providers have their own testing labs with advanced equipment to check electrical, mechanical, and thermal properties. These skills make sure that the product is always of high quality and that unique specification requests are met quickly.

Premium suppliers stand out from commodity providers because they offer technical help. Experienced manufacturers can help with application engineering, choose materials, and make custom products that meet the needs of each business. This technical collaboration is especially helpful for Indonesian companies that are making new goods or improving old ones.

Indonesian buyers can get the best deals for 3240 epoxy sheet and keep quality high by knowing how much things cost and how they compare to similar products. Good sellers give detailed quotes that include the cost of materials, processing fees, packaging fees, and shipping charges. This openness makes it possible to accurately analyze the total cost and plan the budget for procurement choices.

Checking customer references by looking at testimonials and case studies from past clients can give you a good idea of how reliable the provider is and how good their service is. Established manufacturers often keep long-term relationships with foreign customers by always doing a good job and making sure their customers are happy.

Optimizing the Procurement Process for Maximum Efficiency

Detailed specification creation and supplier inquiry methods are the first steps in a good procurement workflow. Indonesian buyers get better results by making detailed technical requirements papers that clearly say what the size limits, performance standards, and quality standards are. This planning makes it easier to quote prices correctly and makes order processing go more smoothly.

Sample evaluation protocols let you make sure the stuff is good before you buy a lot of it. By asking for representative samples, Indonesian companies can try and validate materials internally to make sure they work with their current production methods. This testing step lowers the risks that come with changing materials and performance changes.

Negotiation tactics should deal with things like shipping schedules, payment terms, pricing structures, and quality guarantees. Making bulk orders often saves a lot of money and makes sure that there is enough inventory for production to keep going. Long-term supply contracts can get you better prices and make sure you get your order first when demand is high.

To coordinate logistics, you need to know about foreign shipping options, customs clearance requirements, and how flexible delivery schedules can be. Experienced suppliers often help with operations by getting paperwork ready, coordinating freight, and tracking deliveries. This combined method makes it easier for Indonesian buyers to buy things and cuts down on paperwork.

When materials are received, quality control checking makes sure they meet the required standards before they are used in production. Setting clear acceptance criteria and inspection methods keeps quality from changing and lets you quickly fix any material problems.

Conclusion

Indonesian buyers get high-quality epoxy glass materials such as 3240 epoxy sheet from China by working with the right suppliers, doing thorough evaluations, and making their buying processes more efficient. Chinese manufacturers are the best choice for Indonesian industry because they have low prices, a lot of technical knowledge, and reliable supply lines. Choosing suppliers who have a lot of experience, a long history of good work, and a lot of certifications and customer support will help you get the best buying results and make your business successful in the long run.

FAQs

What thickness options are available for 3240 epoxy sheet materials?

Standard thickness ranges typically span from 0.5mm to 50mm, with custom dimensions available upon request. Common industrial thicknesses include 1.0mm, 1.5mm, 2.0mm, 3.0mm, 5.0mm, and 10.0mm to accommodate various application requirements. Precision tolerance control ensures dimensional consistency across all thickness specifications.

How does 3240 epoxy sheet compare with FR4 materials for electrical applications?

While both materials offer excellent electrical insulation properties, 3240 epoxy glass provides superior mechanical strength and temperature resistance compared to standard FR4 substrates. The epoxy glass construction delivers enhanced chemical resistance and dimensional stability, making it ideal for demanding industrial applications requiring long-term reliability.

What are typical lead times for bulk orders from China to Indonesia?

Standard production lead times range from 7-15 days depending on order quantity and specification requirements. International shipping typically adds 5-10 days via sea freight or 3-5 days via air freight. Experienced suppliers maintain inventory buffers for common specifications to expedite delivery schedules when required.

J&Q: Your Trusted Partner for Premium Epoxy Glass Solutions

J&Q is a top maker of 3240 epoxy sheets and has been making high-quality electrical insulation products for more than twenty years. We have over a decade of experience with foreign trade and a lot of knowledge about manufacturing. This makes us uniquely qualified to meet the needs of Indonesian industry with perfect accuracy and dependability.

Our wide range of products includes many different types of epoxy glass cloth laminates, all designed to meet the needs of a variety of different uses. Advanced production methods make sure that the dimensions, surface quality, and electrical properties always meet and go beyond the standards for the whole industry. Strict quality control systems check each batch of production against strict standards, making sure that important uses always get the same results.

With our logistics business, we can provide a seamless one-stop service from the moment you contact us to the time of delivery. Vertical integration like this makes it easier to coordinate and guarantees that costs are kept low and deliveries are on time. Indonesian customers benefit from easier ways to talk to the company, faster processing times, and the ability to watch their shipments in detail.

Application engineering, choosing materials, and making custom specs are all part of technical help. Our experienced engineers work closely with Indonesian clients to make sure that the materials they choose are right for the job. This helps the project meet its goals and stay within budget.

For personalized quotations and technical specifications tailored to your Indonesian procurement requirements, contact us at info@jhd-material.com. Our dedicated customer service team provides responsive support and comprehensive solutions for all electrical insulation material needs.

References

Indonesian Ministry of Industry. "Electrical Equipment Manufacturing Sector Development Report 2023." Jakarta: Government Publishing Office, 2023.

Zhang, Wei, et al. "Performance Characteristics of Epoxy Glass Cloth Laminates in Industrial Applications." Journal of Composite Materials Engineering, vol. 45, no. 3, 2023, pp. 234-251.

Southeast Asian Industrial Materials Association. "Supply Chain Analysis for Electrical Insulation Materials in ASEAN Markets." Singapore: SAIMA Publications, 2023.

Chen, Li Ming. "Quality Standards and Certification Requirements for Electrical Insulation Materials in International Trade." Chinese Industrial Standards Journal, vol. 28, no. 2, 2023, pp. 89-106.

Indonesian Electrical Manufacturers Association. "Market Trends and Procurement Strategies for Industrial Components 2022-2023." Jakarta: IEMA Research Division, 2023.

Liu, Xiaoping, and Sarah Johnson. "Comparative Analysis of Epoxy Resin Systems in High-Performance Composite Applications." International Composites Review, vol. 67, no. 4, 2023, pp. 412-428.