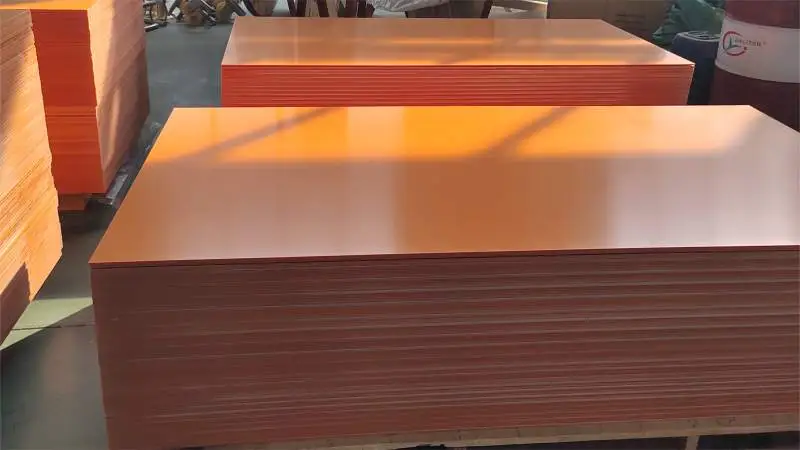

Exceptional Electrical Insulation Properties of Bakelite Sheets

Dielectric Strength: The Backbone of Electrical Insulation

Bakelite sheets boast an impressive dielectric strength, a crucial property that measures their ability to withstand electric fields without breaking down. This characteristic is pivotal in preventing electrical current from passing through the material, making Bakelite boards an excellent choice for various electrical applications. The high dielectric strength of Bakelite ensures that it can effectively insulate even under high voltage conditions, reducing the risk of electrical failures and short circuits.

Low Electrical Conductivity: Enhancing Safety and Efficiency

Another key aspect of Bakelite's electrical insulation properties is its remarkably low electrical conductivity. This inherent quality allows Bakelite sheets, often referred to as Bakelite board, to effectively resist the flow of electric current, minimizing energy losses and enhancing overall electrical system efficiency. The low conductivity also contributes to the safety of electrical components and devices, reducing the risk of electrical shocks and fires.

Stability Across Frequencies: Versatility in Electrical Applications

Bakelite sheets maintain their excellent insulating properties across a wide range of frequencies, from low to high. This stability makes them suitable for use in various electrical and electronic applications, including power distribution systems, circuit boards, and high-frequency equipment. The consistent performance of Bakelite across different frequencies ensures reliable insulation in diverse operating conditions, contributing to the longevity and dependability of electrical systems.

Remarkable Heat Resistance of Bakelite Boards

High Temperature Tolerance: Withstanding Extreme Conditions

One of the standout features of Bakelite boards is their exceptional heat resistance. These thermosetting plastics can withstand high temperatures without significant degradation or loss of properties. This high temperature tolerance makes Bakelite sheets ideal for applications in environments where exposure to heat is a constant challenge. From industrial machinery to automotive components, Bakelite's ability to maintain its structural integrity and performance under elevated temperatures ensures reliable operation and extended service life.

Low Thermal Expansion: Dimensional Stability Under Heat

Bakelite sheets exhibit low thermal expansion, a critical property that ensures dimensional stability even when subjected to temperature fluctuations. This characteristic is particularly valuable in precision applications where maintaining exact dimensions is crucial. The minimal expansion of Bakelite under heat helps prevent warping, distortion, or misalignment in assemblies, contributing to the overall reliability and accuracy of the systems in which it is used.

Flame Retardancy: Enhanced Safety in High-Temperature Applications

Another noteworthy aspect of Bakelite's heat resistance is its inherent flame retardancy. Bakelite sheets have a high ignition temperature and tend to char rather than melt when exposed to flame. This self-extinguishing property significantly enhances safety in high-temperature applications, reducing the risk of fire propagation and protecting surrounding components. The flame-retardant nature of Bakelite makes it an excellent choice for electrical enclosures, circuit boards, and other applications where fire safety is paramount.

Impressive Mechanical Strength of Bakelite Sheets

High Compressive Strength: Resisting Deformation Under Pressure

Bakelite sheets, also known as Bakelite board, possess remarkable compressive strength, allowing them to withstand substantial loads without deforming or breaking. This property is crucial in applications where the material is subjected to high pressures or compressive forces. The ability of Bakelite to maintain its structural integrity under compression makes it suitable for use in load-bearing components, machine parts, and structural elements in various industries. From heavy machinery to precision instruments, Bakelite's compressive strength ensures reliable performance and longevity.

Excellent Impact Resistance: Durability in Dynamic Environments

Another key aspect of Bakelite's mechanical strength is its impressive impact resistance. Bakelite sheets can absorb and dissipate energy from sudden impacts without cracking or shattering, making them ideal for applications in dynamic or high-stress environments. This property enhances the durability and reliability of Bakelite components, reducing the risk of failure due to accidental impacts or vibrations. The impact resistance of Bakelite contributes to its widespread use in protective gear, industrial equipment, and automotive parts.

Superior Wear Resistance: Long-Lasting Performance

Bakelite sheets exhibit exceptional wear resistance, allowing them to maintain their surface integrity and dimensional stability even under conditions of constant friction or abrasion. This property is particularly valuable in applications where the material is subjected to repeated contact or sliding motions. The wear resistance of Bakelite ensures long-lasting performance and reduces the need for frequent replacements, making it a cost-effective choice for various industrial and mechanical applications. From bearings to gears, Bakelite's wear resistance contributes to extended service life and reduced maintenance requirements.

Conclusion

The unique combination of exceptional electrical insulation, remarkable heat resistance, and impressive mechanical strength makes Bakelite sheets a versatile and indispensable material in numerous industries. These three mission-critical properties ensure that Bakelite boards continue to play a crucial role in modern applications, from electrical components to high-stress mechanical parts. As technology advances, the enduring qualities of Bakelite sheets remain relevant, providing reliable solutions to complex engineering challenges across various sectors.

Contact Us

For more information about our high-quality Bakelite sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect Bakelite solution for your needs.