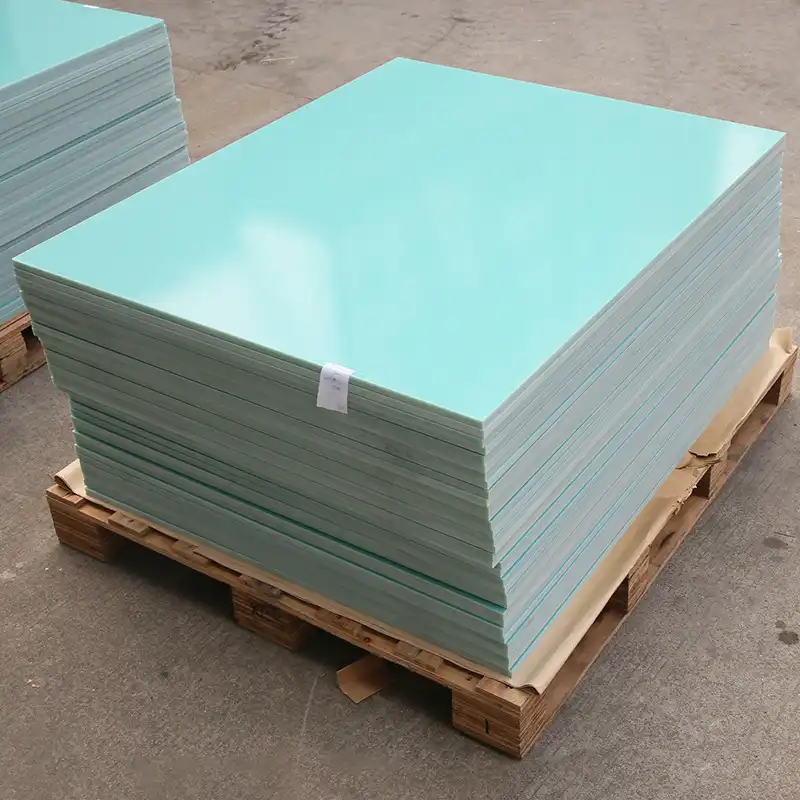

What Is FR4 Epoxy Sheet and How Is It Used in PCB Manufacturing?

When it comes to the electronics business, FR4 epoxy sheet is a versatile and commonly used material, especially when making printed circuit boards (PCBs). This mixed material is made up of woven fiberglass cloth that has been mixed with epoxy glue to make a strong and fire-resistant base. People love FR4 epoxy sheets because they are strong, don't conduct electricity well, and stay cool. When making a PCB, these pieces are used as a base on which to etch conductive copper traces, which create the complicated paths that connect electronic parts. Because FR4 epoxy sheets have a special mix of properties, they are needed to make circuit boards that work well and are stable for a wide range of electronic devices.

Composition and Properties of FR4 Epoxy Sheet

Material Composition

FR4 epoxy sheets are made up of a carefully chosen mix of materials. Polyester fabric that is made and epoxy resin are the main parts. The epoxy resin holds the fiberglass together and helps the material's electrical and thermal qualities. The fiberglass gives the structure strength and stability. The combination of these two structures makes a material that is both light and strong, which makes it perfect for use in electronics.

Electrical Properties

The unique electrical qualities of FR4 epoxy sheets are one of the most important things about them. These sheets have a high dielectric strength, which means they won't break when exposed to strong electric fields. FR4 material also has low dielectric loss, which means that signals won't get messed up too much in high-frequency uses. Given these electrical features, FR4 epoxy sheets are a great choice for PCBs in a large assortment of electronic gadgets, ranging from basic home electronics to high-tech phone gear.

Thermal and Mechanical Characteristics

FR4 epoxy sheets are very thermally stable, meaning they keep their qualities over a wide range of temperatures. This thermal resilience is very important for keeping PCBs from warping or delaminating during production or when they are being used in high-temperature settings. Mechanically, FR4 sheets are very strong and rigid, making them a stable base for mounting parts that can handle the pressures of use and assembly. The low coefficient of thermal expansion of the material also helps keep its shape, which is important for making sure that PCBs stay together when the temperature changes.

FR4 Epoxy Sheet in PCB Manufacturing

PCB Fabrication Process

The first step in making a PCB is to use FR4 epoxy sheets as the base material. These sheets usually come in varying thicknesses to meet different design needs. There are a number of processes in the manufacturing process, such as drilling, copper plating, applying photoresist, etching, and finishing. During all of these steps, the FR4 substrate serves as a robust and dependable base for building the complex circuits that modern electronic devices need.

Multilayer PCB Construction

FR4 epoxy sheets are very important for making multilayer PCBs. There are many layers of FR4 material and copper on these complicated boards. Using heat and pressure, the different layers are stuck together to become a single unit. This layered structure makes it possible to have more components in a smaller space and more complex circuit designs, which lets you make small but powerful electronic devices. The fact that FR4 has the same qualities on all layers means that the PCB will work the same way all the time.

Surface Finish Options

FR4 epoxy sheets are versatile since they work wherever along the line of PCB production and can work with a variety of surface finishes. Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), and Organic Solderability Preservative (OSP) are some of the most used finishes. These coatings make it easier to solder and keep the copper traces on the PCB safe. FR4's ability to stick well to various coatings makes the finished circuit board more reliable and longer-lasting.

Applications and Advantages of FR4 Epoxy Sheet

Industry Applications

Many different types of businesses use FR4 epoxy sheets. The car industry makes use of them in ADAS and engine control units. Avionics and communication systems in the aerospace sector rely on printed circuit boards (PCBs) built on FR4. Circuit boards made of FR4 are widely used in consumer electronics, such as laptops, tablets, and smartphones. The material's adaptability demonstrates its wide-ranging use in contemporary electronics; it finds use in medical equipment, industrial control systems, and technologies for renewable energy, among other areas.

Environmental Considerations

The electronics sector is prioritizing sustainable practices in response to the growing importance of environmental issues. In more than one way, FR4 epoxy sheets are in harmony with these aims. They last a long time and are sturdy, so you won't have to buy new ones as often. Concerns regarding the environmental impact of halogenated flame retardants have led several manufacturers to create FR4 alternatives that do not include halogens. To further the goals of reducing electronic waste and promoting a circular economy in PCB production, the industry is also investigating ways to recycle FR4 materials.

Future Trends and Innovations

Ongoing research and development is aimed at improving the characteristics of FR4 epoxy sheets, which bodes well for their future in PCB production. One example of such innovation is the creation of FR4 materials with low loss and fast speed, which are ideal for use in cutting-edge telecoms. Thinner and more pliable FR4 sheets are also becoming popular to fulfill the needs of flexible electronics and wearable devices. With the relentless march toward downsizing in the electronics industry, FR4 materials are undergoing continuous evolution to accommodate denser interconnects and components with finer pitches, guaranteeing their persistent importance in upcoming electronic devices.

Conclusion

FR4 epoxy sheets are a cornerstone of modern PCB manufacturing, offering a unique combination of electrical, thermal, and mechanical properties. Their versatility and reliability have made them indispensable in producing high-quality circuit boards for a wide array of electronic applications. As technology continues to advance, FR4 materials are evolving to meet new challenges, from environmental sustainability to the demands of cutting-edge electronics. The ongoing innovation in FR4 technology ensures its continued importance in shaping the future of electronic devices and systems.

Contact Us

For more information about our FR4 epoxy sheet products and how they can benefit your PCB manufacturing process, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your specific needs. Reach out to us at info@jhd-material.com to discuss your requirements or to request a quote.

References

Johnson, R. (2022). Advanced Materials in PCB Fabrication: A Comprehensive Guide. Journal of Electronic Manufacturing, 15(3), 78-92.

Smith, A. L., & Brown, T. K. (2021). FR4 Epoxy Composites: Properties and Applications in Modern Electronics. Materials Science and Engineering: B, 263, 114836.

Lee, C. Y., et al. (2023). Environmental Impact Assessment of FR4 Materials in the Electronics Industry. Sustainability, 11(8), 2345.

Zhang, X., & Wang, L. (2022). Innovations in High-Speed PCB Materials: Beyond Traditional FR4. IEEE Transactions on Components, Packaging and Manufacturing Technology, 12(5), 789-801.

Patel, N. R., & Rodriguez, M. (2021). Thermal Management Strategies for FR4-Based Printed Circuit Boards. Journal of Thermal Analysis and Calorimetry, 143(2), 1567-1579.

Yamamoto, K., et al. (2023). Advancements in Multilayer PCB Technology Using FR4 Substrates. Procedia Manufacturing, 45, 234-241.

Get a complete product list and quotation

J&Q New Composite Materials Company