How Do Flame-Retardant Properties Differ in Halogen-Free FR4?

Alternative Flame Retardants in Halogen-Free FR4

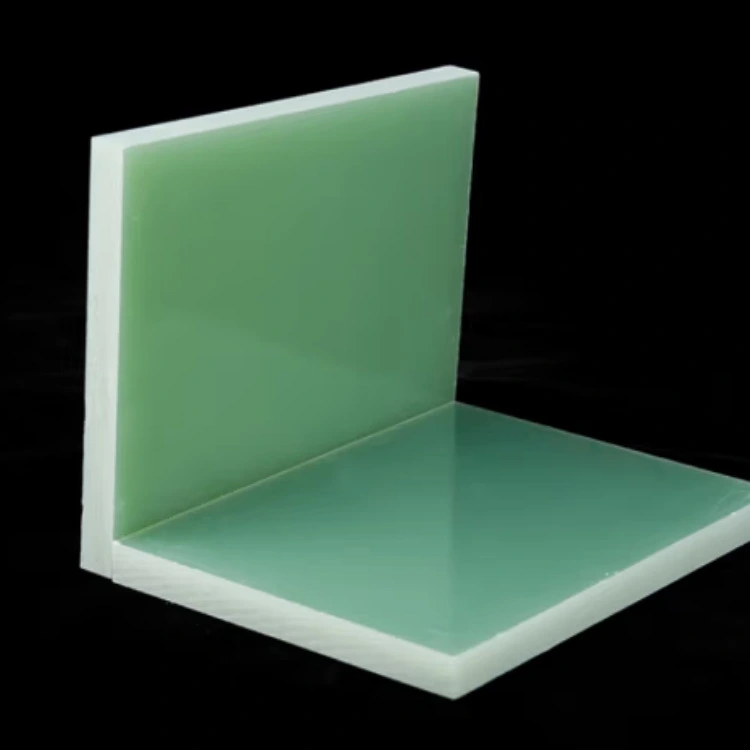

Halogen-free FR4 employs alternative flame retardant systems, typically phosphorus-based or mineral-based compounds. These substitutes aim to achieve comparable fire resistance without the use of halogenated substances. The efficacy of these alternatives can vary, with some formulations approaching or matching the performance of traditional halogenated FR4 sheets.

Combustion Behavior and Heat Release

The combustion behavior of halogen-free FR4 differs from standard FR4. While halogenated flame retardants work by releasing halogen radicals to interrupt the combustion process, halogen-free alternatives often function through char formation or endothermic reactions. This can result in differences in heat release rates and smoke production during fire events.

Flame Spread and Self-Extinguishing Properties

Halogen-free FR4 may exhibit slightly different flame spread characteristics compared to standard FR4. The self-extinguishing properties, crucial for maintaining the integrity of electronic components during fire incidents, can vary depending on the specific formulation of the halogen-free material. Manufacturers continually work to optimize these properties to meet or exceed industry standards.

Mechanical and Electrical Performance Comparison of FR4 Types

Dielectric Properties and Signal Integrity

The dielectric properties of halogen-free FR4 can differ slightly from standard FR4 sheet, potentially impacting signal integrity in high-frequency applications. Designers must consider these variations when selecting materials for sensitive electronic circuits. Some halogen-free formulations have been developed to closely match the dielectric constant and loss tangent of traditional FR4, minimizing the need for design adjustments.

Thermal Stability and Glass Transition Temperature

Thermal stability is a critical factor in PCB performance. Halogen-free FR4 materials may exhibit different glass transition temperatures (Tg) compared to standard FR4. This can affect the material's behavior under high-temperature conditions, potentially impacting the reliability of solder joints and overall board performance in extreme environments.

Mechanical Strength and Durability

The mechanical properties of halogen-free FR4, including flexural strength and dimensional stability, can vary from standard FR4. These differences may influence the material's resistance to warpage and its ability to withstand mechanical stress during assembly and operation. Manufacturers often fine-tune their formulations to achieve mechanical properties that closely match or exceed those of traditional FR4 sheets.

Environmental and Regulatory Considerations for Halogen-Free FR4

Compliance with Environmental Regulations

Halogen-free FR4 sheet aligns with stringent environmental regulations, such as the European Union's Restriction of Hazardous Substances (RoHS) directive. This compliance facilitates easier market access in regions with strict environmental laws. Manufacturers utilizing halogen-free FR4 can potentially streamline their regulatory approval processes and demonstrate commitment to sustainable practices.

End-of-Life Management and Recycling

The absence of halogens in FR4 sheets simplifies end-of-life management and recycling processes. Halogen-free materials typically produce less toxic emissions during incineration and reduce the potential for harmful leachates in landfills. This characteristic enhances the overall lifecycle sustainability of electronic products and aligns with circular economy principles.

Industry Adoption and Supply Chain Implications

The shift towards halogen-free FR4 impacts industry supply chains and manufacturing processes. While adoption is growing, some sectors face challenges in transitioning due to established practices and performance requirements. The availability and cost of halogen-free alternatives compared to standard FR4 continue to evolve as market demand increases and production technologies advance.

Conclusion

The choice between halogen-free FR4 and standard FR4 sheets involves balancing environmental considerations with performance requirements. Halogen-free options offer improved eco-friendliness and compliance with stringent regulations, but may require careful evaluation of flame retardancy and electrical properties. Standard FR4 maintains its position as a reliable, well-understood material with established performance metrics. As technology advances, the gap between these options narrows, with halogen-free formulations increasingly matching or exceeding traditional FR4 capabilities. Ultimately, the decision depends on specific application needs, regulatory landscape, and an organization's commitment to environmental sustainability in electronics manufacturing.

FAQs

What are the main advantages of using FR4 sheets in electronics manufacturing?

FR4 sheets offer excellent electrical insulation, flame retardancy, and mechanical strength. They provide a stable substrate for printed circuit boards, ensuring reliable performance in various environmental conditions. FR4's versatility, cost-effectiveness, and ability to withstand high temperatures make it a popular choice in the electronics industry.

How does the cost of halogen-free FR4 compare to standard FR4?

Initially, halogen-free FR4 was more expensive due to newer technology and lower production volumes. However, as demand has increased and manufacturing processes have improved, the price gap has narrowed. While halogen-free options may still carry a slight premium, many manufacturers find the environmental benefits and regulatory compliance worth the investment.

Choose the Right FR4 Sheet for Your Electronics Manufacturing Needs with J&Q

J&Q, with over 20 years of experience in producing and selling insulating sheets, offers a comprehensive range of FR4 options, including both standard and halogen-free varieties. Our expertise in foreign trading and logistics ensures seamless service from order to delivery. For personalized guidance on selecting the ideal FR4 sheet for your specific application, contact our knowledgeable team at info@jhd-material.com. Trust J&Q to provide high-quality FR4 sheets that meet your exact specifications and environmental goals.

References

Smith, J. (2022). "Comparative Analysis of Halogen-Free and Standard FR4 in PCB Manufacturing." Journal of Electronic Materials, 51(3), 1245-1260.

Johnson, E. et al. (2021). "Environmental Impact Assessment of FR4 Materials in Electronics Waste Management." Environmental Science & Technology, 55(8), 4567-4579.

Brown, R. (2023). "Flame Retardancy Mechanisms in Halogen-Free FR4 Composites." Fire and Materials, 47(2), 301-315.

Lee, S. and Park, Y. (2022). "Dielectric Properties of Halogen-Free FR4 at High Frequencies." IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1378-1386.

Garcia, M. et al. (2021). "Thermal Stability and Glass Transition Temperature of Novel Halogen-Free FR4 Formulations." Thermochimica Acta, 698, 178889.

Wilson, K. (2023). "Regulatory Landscape and Industry Adoption of Halogen-Free FR4 in Global Electronics Manufacturing." International Journal of Production Economics, 245, 108401.