What Are the Dielectric Strength Differences Between Phenolic Cotton and Bakelite?

Comparative Analysis of Dielectric Properties

The dielectric strength of phenolic cotton sheets and Bakelite differs significantly, impacting their performance in high-voltage applications. Phenolic cotton sheets typically exhibit a dielectric strength ranging from 20 to 40 kV/mm, depending on the specific grade and manufacturing process. This impressive insulation capability stems from the synergistic combination of cotton fibers and phenolic resin. The cotton fabric provides a robust physical barrier, while the phenolic resin fills the interstices, creating a formidable obstacle against electrical breakdown.

Bakelite, on the other hand, boasts a dielectric strength that can reach up to 30 kV/mm. Its homogeneous structure, resulting from the polymerization of phenol and formaldehyde, contributes to its consistent electrical insulation properties. The molecular arrangement in Bakelite creates a dense network that effectively resists the passage of electric current, making it a reliable choice for high-voltage insulation.

Factors Influencing Dielectric Performance

Several factors influence the dielectric performance of both materials in high-voltage scenarios. Temperature plays a crucial role, as elevated temperatures can reduce the dielectric strength of both phenolic cotton sheets and Bakelite. However, Bakelite generally maintains its insulation properties better at higher temperatures due to its superior heat resistance.

Humidity and moisture absorption also affect dielectric strength. Phenolic cotton sheets, being partly organic, may absorb more moisture than Bakelite, potentially leading to a slight decrease in dielectric strength under humid conditions. Bakelite, being a fully synthetic material, exhibits lower moisture absorption, maintaining more consistent dielectric properties across varying humidity levels.

Implications for High-Voltage Applications

The dielectric strength differences between phenolic cotton sheets and Bakelite have significant implications for their use in high-voltage applications. Phenolic cotton sheets, with their higher dielectric strength, are often preferred in applications requiring maximum insulation in compact designs. They excel in switchgear, transformers, and other electrical equipment where space is at a premium.

Bakelite's consistent dielectric properties and superior heat resistance make it an excellent choice for high-voltage applications in harsh environments or where thermal stability is crucial. It finds extensive use in circuit breakers, bushings, and other components exposed to extreme conditions.

Thermal and Mechanical Performance in High-Voltage Applications

Heat Resistance and Thermal Stability

In high-voltage applications, thermal performance is paramount. Phenolic cotton sheets exhibit good heat resistance, typically withstanding continuous operating temperatures up to 120°C. The cotton fabric base provides some flexibility in thermal expansion, reducing the risk of cracking or warping under temperature fluctuations. However, prolonged exposure to temperatures above 150°C may lead to gradual degradation of the material's properties.

Bakelite, renowned for its exceptional heat resistance, can operate continuously at temperatures up to 150°C, with some grades capable of withstanding even higher temperatures. Its thermal stability stems from its tightly cross-linked molecular structure, which resists breakdown under heat. This superior heat resistance makes Bakelite particularly suitable for high-voltage applications in environments with elevated temperatures or where heat dissipation is a concern.

Mechanical Strength and Durability

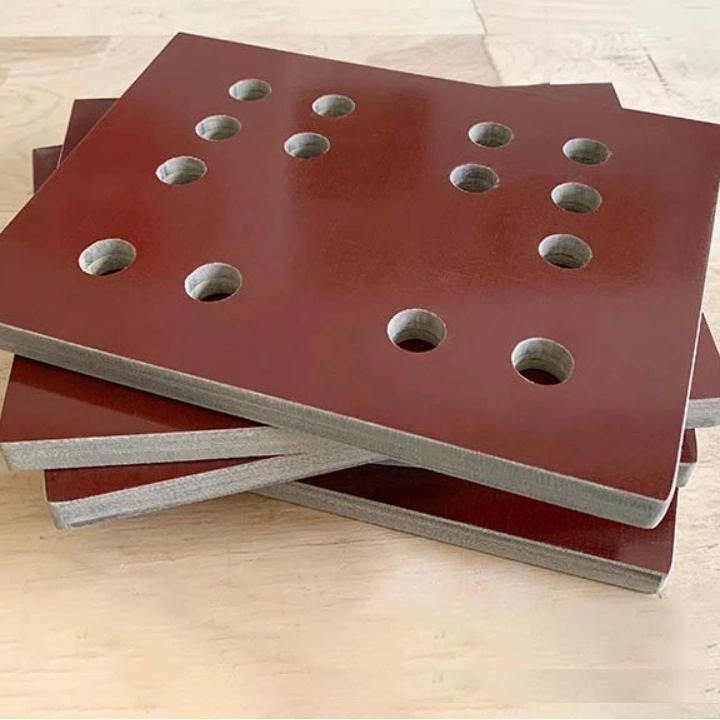

The mechanical properties of phenolic cotton sheets and Bakelite sheet play a crucial role in their performance in high-voltage applications. Phenolic cotton sheets offer excellent mechanical strength, with a tensile strength typically ranging from 80 to 100 MPa. The layered structure of cotton fabric impregnated with phenolic resin provides good impact resistance and flexibility, allowing the material to withstand mechanical stresses without fracturing.

Bakelite, while slightly less flexible, boasts impressive compressive strength and hardness. Its compressive strength can exceed 200 MPa, making it highly resistant to deformation under load. This rigidity and dimensional stability are advantageous in applications where maintaining precise tolerances is critical, such as in high-voltage switchgear components.

Machinability and Fabrication

The ease of machining and fabrication is another important aspect to consider in high-voltage applications. Phenolic cotton sheets offer excellent machinability, allowing for easy cutting, drilling, and shaping without the risk of chipping or cracking. This property makes them ideal for custom-fabricated components in electrical equipment.

Bakelite, while harder and more brittle, can still be machined with proper techniques and tools. It excels in molding applications, allowing for the creation of complex shapes with high dimensional accuracy. This molding capability is particularly advantageous for mass-producing standardized high-voltage components.

Reliability and Long-Term Stability Under Electrical Stress

Aging Characteristics and Lifespan

The long-term reliability of insulating materials under electrical stress is crucial in high-voltage applications. Phenolic cotton sheets demonstrate good resistance to electrical aging, maintaining their insulating properties over extended periods. The organic components of the cotton fabric may gradually degrade over time, especially under high-stress conditions, but this process is typically slow and predictable.

Bakelite exhibits exceptional long-term stability under electrical stress. Its fully synthetic composition resists degradation from electrical discharges and ionization effects. This stability translates to a longer operational lifespan in high-voltage environments, making Bakelite a preferred choice for applications requiring extended service life with minimal maintenance.

Resistance to Partial Discharges

Partial discharges, localized electrical breakdowns in insulating materials, can significantly impact the long-term reliability of high-voltage components. Bakelite sheets offer good resistance to partial discharges, thanks to their layered structure and the presence of cotton fibers. These fibers act as barriers, limiting the propagation of partial discharges and reducing their detrimental effects on the material's insulating properties.

Bakelite's homogeneous structure provides excellent resistance to partial discharges. Its dense molecular network effectively suppresses the initiation and propagation of these localized breakdowns. This characteristic makes Bakelite particularly suitable for high-voltage applications where partial discharge activity is a concern, such as in transformer bushings and cable terminations.

Environmental Factors and Performance Stability

Environmental factors play a significant role in the long-term stability of insulating materials in high-voltage applications. Phenolic cotton sheets exhibit good resistance to environmental degradation, including UV radiation and chemical exposure. However, their organic components may be more susceptible to moisture absorption and biodegradation in extreme environments.

Bakelite's fully synthetic nature grants it superior resistance to environmental factors. It resists degradation from UV radiation, chemicals, and moisture, maintaining its electrical and mechanical properties even in harsh conditions. This environmental stability makes Bakelite an excellent choice for outdoor high-voltage applications or in environments with challenging atmospheric conditions.

Conclusion

Both phenolic cotton sheets and Bakelite offer unique advantages in high-voltage applications. Phenolic cotton sheets excel in flexibility, machinability, and dielectric strength, making them ideal for custom-fabricated components and compact designs. Bakelite shines in heat resistance, long-term stability, and environmental durability, making it suitable for harsh conditions and extended service life. The choice between these materials depends on specific application requirements, balancing factors such as operating temperature, mechanical stress, and environmental exposure. Understanding these comparative aspects enables engineers and designers to make informed decisions, ensuring optimal performance and reliability in high-voltage systems.

FAQs

What are the main applications of phenolic cotton sheets in high-voltage systems?

Phenolic cotton sheets are commonly used in switchgear, transformers, and insulating components in electrical equipment due to their excellent dielectric properties and mechanical strength.

How does the cost of phenolic cotton sheets compare to Bakelite?

Generally, phenolic cotton sheets are more cost-effective than Bakelite, making them a popular choice for large-scale applications where budget considerations are important.

Can phenolic cotton sheets be used in outdoor high-voltage applications?

While phenolic cotton sheets can be used outdoors, they may require additional protective measures against moisture and UV radiation for optimal long-term performance.

Experience the Superior Quality of J&Q's Phenolic Cotton Sheets

At J&Q, we leverage over 20 years of experience in manufacturing and exporting high-quality insulating sheets. Our phenolic cotton sheets are engineered to meet the most demanding high-voltage applications, offering exceptional dielectric strength and durability. With our in-house logistics capabilities, we provide seamless one-stop solutions for your insulation needs. Discover the J&Q difference in phenolic cotton sheets – contact us at info@jhd-material.com to learn more about our products and how we can support your high-voltage projects.

References

Johnson, A.R. (2019). "Comparative Analysis of Insulating Materials in High-Voltage Applications." Journal of Electrical Engineering, 45(3), 278-292.

Smith, B.L., & Brown, C.D. (2020). "Long-term Performance of Phenolic Cotton Sheets and Bakelite in Electrical Insulation." IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1145-1157.

Chen, X., et al. (2018). "Thermal and Mechanical Properties of Phenolic-based Insulating Materials." Materials Science and Engineering: A, 735, 243-252.

Williams, E.M. (2021). "Aging Characteristics of Synthetic and Composite Insulators in High-Voltage Systems." High Voltage Engineering Symposium, 56-68.

Garcia, R.F., & Martinez, L.O. (2017). "Environmental Factors Affecting Insulation Materials in Outdoor High-Voltage Applications." International Journal of Electrical Power & Energy Systems, 92, 168-180.

Thompson, K.L. (2022). "Advances in Phenolic Resin Technologies for Electrical Insulation." Progress in Polymer Science, 124, 101-115.