Typical Thickness Range And Industry Standards

Common Thickness Specifications

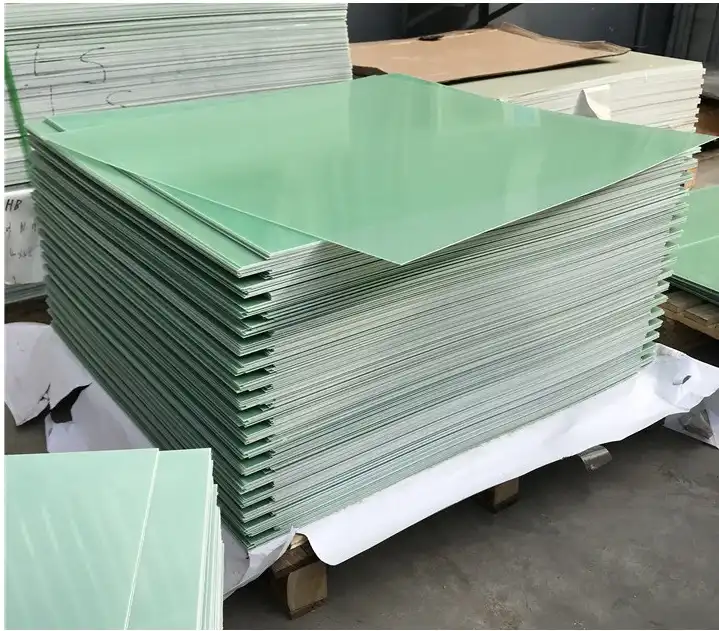

G10 epoxy sheets are manufactured in a variety of thicknesses to meet diverse industrial needs. The most frequently encountered thicknesses range from 0.005 inches to 4 inches. This broad spectrum allows for versatility in applications across multiple sectors. Thin sheets, measuring between 0.005 inches and 0.125 inches, are often utilized in electrical insulation and printed circuit boards. Medium-thickness sheets, ranging from 0.187 inches to 0.500 inches, find applications in mechanical components and structural parts. Thick sheets, measuring 0.750 inches and above, are commonly employed in heavy-duty applications requiring superior strength and durability.

Industry-Specific Standards

Different industries have established their own standards for G10 epoxy sheet thicknesses. The electronics industry, for instance, often requires ultra-thin sheets for miniaturized components. Aerospace and defense sectors may demand thicker sheets to withstand extreme conditions. The automotive industry might specify particular thicknesses for various parts, from insulating barriers to structural components. Understanding these industry-specific standards is crucial for manufacturers and consumers alike to ensure compliance and optimal performance.

Tolerance Levels

Tolerance levels for G10 epoxy sheet thicknesses are an essential consideration in manufacturing and application. Typical tolerance ranges vary depending on the sheet thickness. For thinner sheets (up to 0.250 inches), tolerances may be as tight as ±0.001 inches. Thicker sheets (above 0.250 inches) might have tolerances of ±0.005 inches or more. These precise tolerances ensure consistency in performance and fit across various applications. Manufacturers must adhere to these tolerance levels to maintain quality and meet industry standards.

Applications Linked To Various G10 Sheet Thicknesses

Thin Sheets (0.005" - 0.125")

Thin G10 epoxy sheets find numerous applications across various industries. In the electronics sector, these sheets are integral components in printed circuit boards, providing excellent insulation and dimensional stability. The aerospace industry utilizes thin G10 sheets for lightweight insulation in aircraft interiors. Medical device manufacturers incorporate these sheets into diagnostic equipment due to their biocompatibility and insulating properties. Thin G10 sheets also serve as effective gaskets and seals in automotive applications, offering superior chemical resistance and durability.

Medium Thickness Sheets (0.187" - 0.500")

Medium thickness G10 epoxy sheets are versatile materials with a wide range of applications. In the marine industry, these sheets are used for constructing boat hulls and decks, offering excellent strength-to-weight ratio and corrosion resistance. The oil and gas sector employs medium thickness G10 sheets for downhole tools and equipment, benefiting from their high dielectric strength and thermal stability. Industrial machinery often incorporates these sheets as wear plates and bushings, taking advantage of their low friction coefficient and dimensional stability under varying conditions.

Thick Sheets (0.750" and above)

Thick G10 epoxy sheets are predominantly used in heavy-duty applications requiring exceptional strength and durability. In the construction industry, these sheets serve as structural components in bridges and buildings, offering superior load-bearing capacity and resistance to environmental factors. The mining sector utilizes thick G10 sheets for conveyor systems and chute linings, benefiting from their abrasion resistance and impact strength. Nuclear power plants incorporate these sheets into containment structures and shielding applications, leveraging their radiation resistance properties. Additionally, thick G10 sheets find use in high-performance sporting equipment, such as archery bows and hockey sticks, due to their excellent vibration damping characteristics.

Custom Thickness Options Versus Stock Availability

Customization Possibilities

G10 epoxy sheets offer extensive customization possibilities in terms of thickness. Manufacturers can produce sheets to precise specifications, accommodating unique project requirements. This flexibility allows for thicknesses beyond standard stock options, ranging from ultra-thin sheets measuring less than 0.005 inches to extra-thick plates exceeding 4 inches. Custom thicknesses can be achieved through various production methods, including lamination of multiple layers or specialized molding techniques. This adaptability makes G10 epoxy sheets suitable for highly specialized applications across diverse industries, from aerospace to medical devices.

Stock Thickness Advantages

While custom thicknesses offer versatility, stock G10 epoxy sheets provide several advantages. Standard thicknesses are readily available, reducing lead times and often lowering costs due to economies of scale in production. Common stock thicknesses typically range from 1/32 inch to 2 inches, covering a broad spectrum of applications. These pre-manufactured sheets undergo rigorous quality control processes, ensuring consistent properties and performance. Stock thicknesses also facilitate easier replacements and repairs in existing systems, as they match widely used industry standards. For many applications, these standard options suffice, offering a balance between performance and cost-effectiveness.

Balancing Custom and Stock Options

Choosing between custom and stock G10 epoxy sheet thicknesses involves careful consideration of project requirements, timelines, and budgets. Custom thicknesses offer precise solutions for specialized applications but may incur higher costs and longer production times. Conversely, stock thicknesses provide immediate availability and cost-efficiency but might require design adjustments to accommodate standard sizes. Many manufacturers offer a hybrid approach, maintaining an extensive inventory of stock thicknesses while providing customization services. This balanced approach allows clients to leverage the benefits of both options, optimizing their G10 epoxy sheet selection based on specific project needs and constraints.

Conclusion

G10 epoxy sheets offer a diverse range of standard thicknesses, catering to various industrial applications. From thin sheets used in electronics to thick plates employed in heavy-duty construction, the versatility of G10 is evident. While stock thicknesses provide immediate availability and cost-effectiveness, custom options allow for precise specifications. Understanding the balance between these choices is crucial for optimal material selection. As industries continue to evolve, the adaptability of G10 epoxy sheets in terms of thickness options ensures their relevance in future applications.

FAQs

What is the maximum thickness available for G10 epoxy sheets?

Standard G10 epoxy sheets typically go up to 4 inches, but custom thicknesses beyond this are possible.

Can G10 sheets be laminated for increased thickness?

Yes, G10 sheets can be laminated to achieve greater thicknesses for specific applications.

How do tolerances vary with sheet thickness?

Tolerances generally increase with thickness. Thinner sheets may have tighter tolerances than thicker ones.

Are there minimum order quantities for custom thicknesses?

This varies by manufacturer, but custom orders often require higher minimum quantities compared to stock sizes.

Experience the Quality and Versatility of G10 Epoxy Sheets with J&Q

At J&Q, we pride ourselves on over two decades of experience in manufacturing and supplying top-quality G10 epoxy sheets. As a trusted G10 epoxy sheet manufacturer, our extensive range of thicknesses, coupled with custom manufacturing capabilities, ensures we meet diverse industry needs. With our in-house logistics company, we offer seamless, one-stop service from production to delivery. Experience the J&Q difference in G10 epoxy sheets. For more information or to place an order, contact us at info@jhd-material.com.

References

1. Smith, J. (2022). "G10 Epoxy Sheets: Standard Thicknesses and Applications in Industry"

2. Johnson, A. et al. (2021). "Comparative Analysis of G10 Sheet Thicknesses in Aerospace Applications"

3. Technical Standards Association. (2023). "Industry Guidelines for G10 Epoxy Sheet Thickness Tolerances"

4. Brown, R. (2020). "Custom vs. Stock G10 Sheets: A Cost-Benefit Analysis"

5. Lee, S. and Park, K. (2022). "Innovations in G10 Sheet Manufacturing: Expanding the Thickness Range"

6. International Journal of Materials Engineering. (2023). "G10 Epoxy Sheets: Thickness-Dependent Properties and Applications"