Composition and Manufacturing of Phenolic Cotton Sheets

Raw Materials and Their Properties

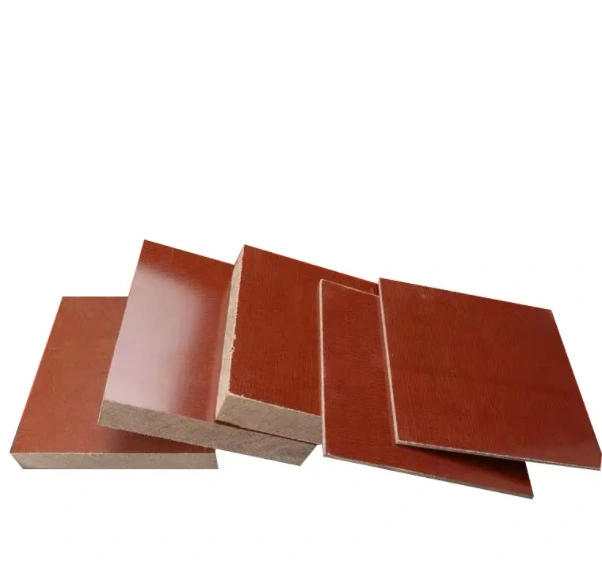

Phenolic cotton sheets are composed of two primary materials: cotton fabric and phenolic resin. The cotton fabric serves as the base material, providing strength and flexibility to the final product. Cotton is chosen for its natural insulating properties and ability to absorb phenolic resin effectively. The phenolic resin, derived from phenol and formaldehyde, acts as the binding agent and imparts additional insulating properties to the sheet.

Manufacturing Process

The manufacturing process of phenolic cotton sheets involves several steps. Initially, the cotton fabric is impregnated with phenolic resin using a specialized impregnation machine. This process ensures that the resin penetrates the fabric thoroughly. After impregnation, the material undergoes a drying process to remove excess moisture. The semi-dried sheets are then stacked and subjected to high pressure and temperature in a hydraulic press. This curing process allows the phenolic resin to polymerize, creating a strong bond with the cotton fibers and resulting in a dense, uniform sheet known as phenolic cotton cloth board.

Quality Control Measures

To ensure the reliability and consistency of phenolic cotton sheets, manufacturers implement rigorous quality control measures throughout the production process. These measures include monitoring resin content, controlling curing conditions, and conducting various tests to verify the mechanical and electrical properties of the finished product. Advanced testing equipment, such as dielectric strength testers and tensile testing machines, are utilized to assess the performance characteristics of the sheets.

Electrical Properties and Applications

Dielectric Strength and Insulation Resistance

One of the most crucial properties of phenolic cotton sheets is their high dielectric strength. This characteristic allows the material to withstand strong electric fields without breaking down, making it ideal for use in high-voltage applications. The dielectric strength of phenolic cotton sheets typically ranges from 15 to 20 kV/mm, depending on the specific grade and thickness of the material. Additionally, these sheets exhibit excellent insulation resistance, effectively preventing current leakage in electrical systems.

Thermal Conductivity and Heat Resistance

Phenolic cotton sheets possess low thermal conductivity, which contributes to their effectiveness as electrical insulators. This property helps prevent heat transfer between conductive components, reducing the risk of thermal damage to sensitive electrical equipment. Moreover, these sheets demonstrate remarkable heat resistance, maintaining their insulating properties and structural integrity even at elevated temperatures. The heat resistance of phenolic cotton sheets typically ranges from 120°C to 130°C, making them suitable for use in various high-temperature electrical applications.

Common Applications in Electrical Systems

The unique combination of electrical and mechanical properties makes phenolic cotton sheets versatile materials for numerous electrical applications. Some common uses include:

- Insulation in transformers and motors

- Switchgear components

- Circuit board substrates

- Electrical panel barriers

- Busbar insulation

- Terminal blocks and connectors

These applications leverage the material's ability to provide reliable insulation, mechanical support, and heat resistance in various electrical environments.

Advantages and Considerations for Using Phenolic Cotton Sheets

Mechanical Strength and Durability

Phenolic cotton sheets, also known as phenolic cotton cloth board, offer exceptional mechanical strength, making them resistant to physical damage and wear. The combination of cotton fibers and cured phenolic resin results in a material that can withstand significant mechanical stress without deformation or failure. This durability ensures long-term reliability in electrical applications, reducing the need for frequent replacements and maintenance. The material's ability to maintain its structural integrity under various environmental conditions further contributes to its longevity in electrical systems.

Chemical Resistance and Environmental Stability

Another notable advantage of phenolic cotton sheets is their resistance to a wide range of chemicals and environmental factors. The cured phenolic resin provides excellent protection against oils, solvents, and mild acids, preventing degradation of the material's electrical and mechanical properties. This chemical resistance is particularly valuable in industrial applications where exposure to harsh substances is common. Furthermore, phenolic cotton sheets exhibit good dimensional stability across a range of temperatures and humidity levels, ensuring consistent performance in diverse operating conditions.

Cost-effectiveness and Availability

When considering insulation materials for electrical applications, the cost-effectiveness of phenolic cotton sheets is a significant factor. These sheets offer a balance between performance and affordability, making them an attractive option for both small-scale projects and large-scale manufacturing. The raw materials used in their production are readily available, contributing to consistent supply and competitive pricing. Additionally, the long service life of phenolic cotton sheets in electrical applications translates to reduced replacement costs over time, further enhancing their economic value.

Conclusion

Phenolic cotton sheets stand out as a versatile and reliable material for electrical insulation applications. Their unique combination of electrical properties, mechanical strength, and thermal resistance makes them an ideal choice for a wide range of electrical systems. By understanding the composition, manufacturing process, and key characteristics of phenolic cotton sheets, professionals in the electrical and manufacturing industries can make informed decisions when selecting insulation materials. As technology continues to advance, the role of high-performance insulation materials like phenolic cotton sheets will remain crucial in ensuring the safety, efficiency, and reliability of electrical systems across various sectors.

Contact Us

For more information about our high-quality phenolic cotton sheets and how they can benefit your electrical applications, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.