Understanding the Composition and Properties of G10 Fiberglass Sheet

The Unique Composition of G10 Fiberglass Sheet

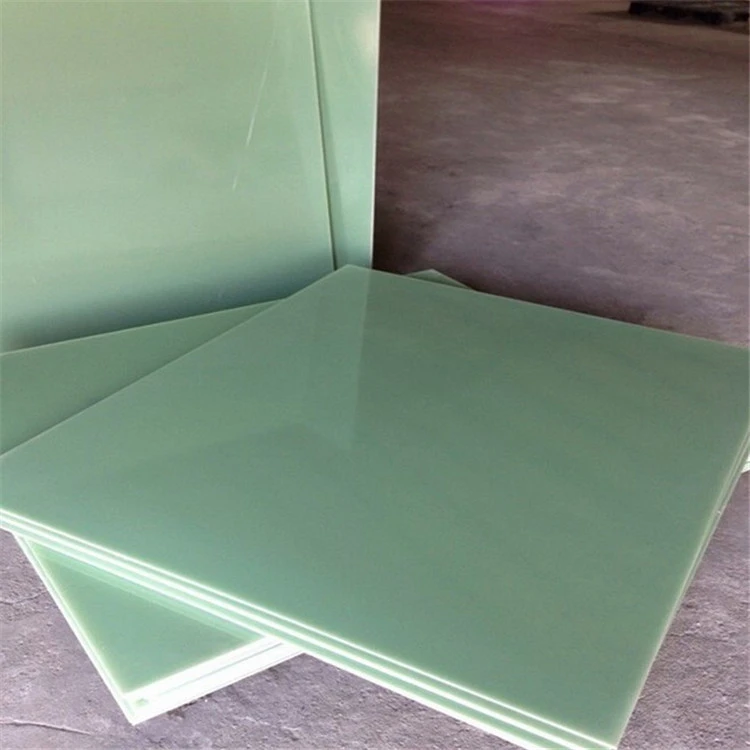

G10 fiberglass sheet is a composite material meticulously crafted from multiple layers of woven glass fabric impregnated with epoxy resin. This sophisticated combination results in a laminate that boasts exceptional strength and durability. The glass fibers provide structural reinforcement, while the epoxy resin acts as a binding agent, creating a cohesive and resilient material.

The manufacturing process involves carefully layering the glass fabric and applying the epoxy resin under controlled pressure and temperature conditions. This precise method ensures optimal bonding between the components, yielding a uniform and high-quality product. The result is a sheet material that exhibits remarkable mechanical and electrical properties, setting it apart from conventional insulation materials.

Mechanical Properties of G10 Fiberglass Sheet

G10 fiberglass sheet possesses an impressive array of mechanical properties that contribute to its widespread use across various industries. Its high tensile strength allows it to withstand substantial loads without deforming or breaking, making it suitable for applications where structural integrity is paramount. The material also exhibits excellent compressive strength, enabling it to resist crushing forces effectively.

Furthermore, G10 fiberglass sheet demonstrates remarkable flexural strength, allowing it to bend without fracturing. This property is particularly valuable in applications where the material may be subjected to bending stresses. The sheet's high impact resistance adds another layer of durability, protecting against sudden shocks or impacts that could compromise its integrity.

One of the standout features of G10 fiberglass sheet is its exceptional dimensional stability. It maintains its shape and size even under varying temperature and humidity conditions, ensuring consistent performance in diverse environments. This stability is crucial in precision applications where maintaining exact dimensions is essential.

Electrical and Thermal Properties of G10 Fiberglass Sheet

G10 fiberglass sheet shines in electrical applications due to its outstanding dielectric properties. It possesses high dielectric strength, which measures its ability to withstand electric fields without breaking down. This characteristic makes it an excellent insulator, preventing the flow of electrical current between conductive components.

The material also boasts low dielectric loss, meaning it efficiently resists the absorption of electrical energy. This property is crucial in high-frequency applications where energy conservation is paramount. Additionally, G10 fiberglass sheet maintains its electrical properties across a wide range of temperatures, ensuring reliable performance in varying thermal conditions.

From a thermal perspective, G10 fiberglass sheet exhibits low thermal conductivity, making it an effective insulator against heat transfer. This property is valuable in applications where thermal management is critical, such as in electronic devices or industrial equipment. The material's ability to withstand high temperatures without degrading further enhances its versatility in demanding environments.

Applications and Industries Benefiting from G10 Fiberglass Sheet

Aerospace and Defense Applications

The aerospace and defense industries heavily rely on G10 fiberglass sheet for its exceptional combination of mechanical strength, lightweight nature, and electrical insulation properties. In aircraft construction, G10 fiberglass sheet finds application in structural components, interior panels, and electrical systems. Its high strength-to-weight ratio contributes to fuel efficiency without compromising on durability.

In satellite and spacecraft design, G10 fiberglass sheet serves as a critical material for thermal insulation and electromagnetic shielding. Its ability to maintain stable properties in extreme temperature conditions makes it ideal for space applications. Moreover, the material's resistance to radiation further enhances its suitability for extraterrestrial environments.

Defense applications leverage G10 fiberglass sheet in various ways, including in the production of military-grade printed circuit boards, missile components, and protective gear. The material's high impact resistance and electrical insulation properties make it valuable in creating robust and reliable defense systems.

Electronics and Electrical Engineering

The electronics industry extensively utilizes G10 fiberglass sheet in the manufacture of printed circuit boards (PCBs). Its excellent dielectric properties, dimensional stability, and heat resistance make it an ideal substrate for PCBs used in computers, smartphones, and other electronic devices. The material's low moisture absorption rate ensures the long-term reliability of these critical components.

In electrical engineering applications, G10 fiberglass sheet serves as an insulator in high-voltage equipment, transformers, and switchgear. Its high dielectric strength and arc resistance properties provide essential safety features in electrical systems. The material's ability to maintain its insulating properties under varying environmental conditions contributes to the reliability of electrical infrastructure.

G10 fiberglass sheet also finds application in the production of electrical connectors, terminal blocks, and insulating spacers. Its machinability allows for precise fabrication of complex shapes, enabling the creation of custom components for specialized electrical applications.

Industrial and Automotive Sectors

In the industrial sector, G10 fiberglass sheet plays a crucial role in various applications due to its exceptional mechanical and chemical resistance properties. It is commonly used in the fabrication of industrial gaskets, seals, and washers, where its ability to withstand high pressures and temperatures is invaluable. The material's low creep characteristics ensure long-term dimensional stability in these applications.

Chemical processing industries benefit from G10 fiberglass sheet's resistance to a wide range of chemicals and solvents. It is used in the construction of chemical storage tanks, pump components, and piping systems where corrosion resistance is paramount. The material's low moisture absorption rate further enhances its suitability for these challenging environments.

In the automotive industry, G10 fiberglass sheet contributes to the development of lightweight yet strong components. It is used in the production of underhood insulators, electrical components, and structural reinforcements. The material's ability to withstand high temperatures and vibrations makes it ideal for various automotive applications, contributing to improved vehicle performance and efficiency.

Advantages and Considerations of Using G10 Fiberglass Sheet

Key Advantages of G10 Fiberglass Sheet

G10 fiberglass sheet offers a multitude of advantages that make it a preferred choice across various industries. Its exceptional strength-to-weight ratio allows for the creation of lightweight yet durable components, contributing to improved efficiency in applications where weight is a critical factor. The material's high dimensional stability ensures that products maintain their shape and size even under challenging environmental conditions, promoting reliability and precision in manufacturing processes.

The excellent electrical insulation properties of G10 fiberglass sheet make it invaluable in electrical and electronic applications. Its high dielectric strength and low dielectric loss contribute to the efficient and safe operation of electrical systems. Furthermore, the material's low moisture absorption rate enhances its long-term performance and reliability, particularly in humid environments.

G10 fiberglass sheet's versatility is another significant advantage. It can be easily machined, cut, and shaped using conventional tools, allowing for the creation of complex geometries and custom components. This flexibility in fabrication makes it adaptable to a wide range of applications across different industries.

Environmental and Safety Considerations

While G10 fiberglass sheet offers numerous benefits, it's essential to consider environmental and safety aspects associated with its use. The production process of G10 fiberglass sheet involves the use of epoxy resins, which can have environmental implications. However, advancements in manufacturing techniques have led to the development of more eco-friendly epoxy systems, reducing the environmental impact.

From a safety perspective, proper handling and fabrication practices are crucial when working with G10 fiberglass sheet. Cutting or machining the material can generate dust particles, necessitating appropriate personal protective equipment (PPE) and ventilation systems. Adhering to recommended safety guidelines ensures the well-being of workers involved in the production and processing of G10 fiberglass sheet.

It's worth noting that G10 fiberglass sheet, once cured, is generally considered inert and does not pose significant health risks during normal use. However, proper disposal methods should be employed at the end of the product's lifecycle to minimize environmental impact.

Cost Analysis and Long-Term Value

When evaluating the use of G10 fiberglass sheet, it's important to consider both the initial cost and the long-term value it provides. While the upfront cost of G10 fiberglass sheet may be higher compared to some alternative materials, its durability and performance characteristics often result in significant cost savings over time.

The material's resistance to wear, corrosion, and environmental factors contributes to extended product lifespans, reducing the need for frequent replacements. This longevity can lead to lower maintenance costs and improved operational efficiency in various applications. Additionally, the lightweight nature of G10 fiberglass sheet can result in reduced transportation and installation costs, further enhancing its economic value.

In industries where precision and reliability are paramount, such as aerospace and electronics, the use of G10 fiberglass sheet can lead to improved product performance and reduced failure rates. These factors contribute to enhanced customer satisfaction and potentially increased market share, providing intangible but significant long-term benefits.

Conclusion

G10 fiberglass sheet stands as a testament to the power of innovative materials in advancing various industries. Its unique combination of mechanical strength, electrical insulation properties, and versatility make it an indispensable component in aerospace, electronics, and industrial applications. As technology continues to evolve, G10 fiberglass sheet is poised to play an increasingly important role in the development of high-performance, reliable products across diverse sectors. By understanding its properties, applications, and considerations, manufacturers and engineers can harness the full potential of this remarkable material to drive innovation and efficiency in their respective fields.

Contact Us

To learn more about our high-quality G10 fiberglass sheet products and how they can benefit your specific application, please don't hesitate to contact our team of experts. We're here to provide you with personalized solutions and support. Reach out to us at info@jhd-material.com for more information or to discuss your project requirements.