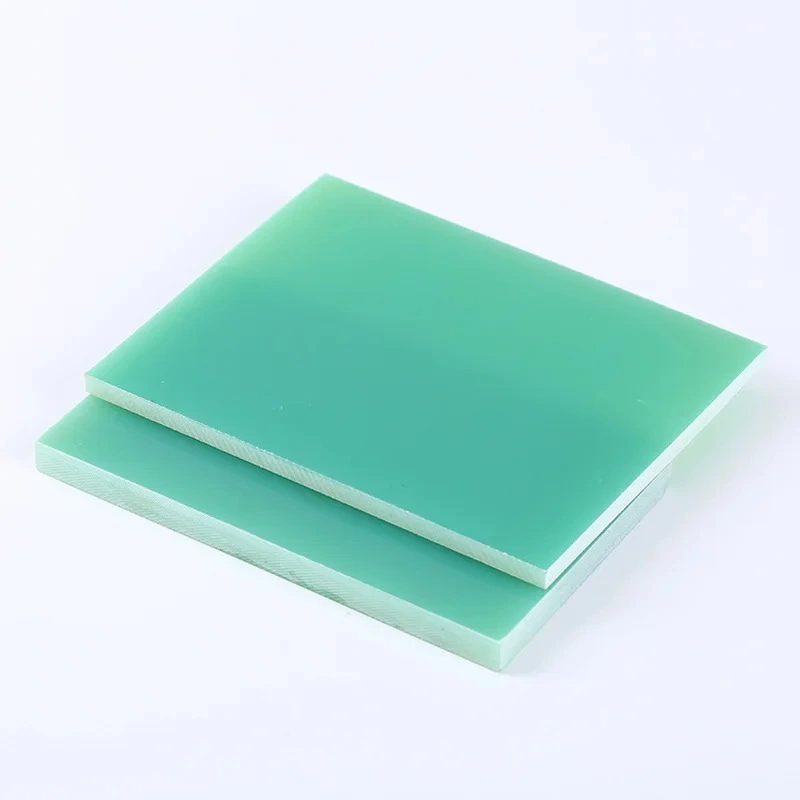

Properties and Characteristics of Epoxy Laminates

Electrical Insulation Properties

Epoxy laminates exhibit exceptional electrical insulation properties, making them invaluable in industrial automation equipment. These materials boast high dielectric strength, low dielectric constant, and impressive volume resistivity. Such characteristics ensure that electrical signals remain uncompromised, preventing short circuits and enhancing the overall reliability of automated systems. The superior insulation properties of epoxy laminates contribute to the longevity and performance of sensitive electronic components, safeguarding them against electrical interference and breakdown.

Mechanical Strength and Durability

One of the standout features of epoxy laminates is their remarkable mechanical strength and durability. These materials demonstrate high tensile strength, flexural strength, and impact resistance, enabling them to withstand the rigors of industrial environments. The robust nature of epoxy laminates ensures that automation equipment remains structurally sound, even when subjected to vibrations, shocks, and other mechanical stresses. This durability translates to reduced maintenance requirements and extended equipment lifespan, ultimately contributing to improved operational efficiency and cost-effectiveness in industrial settings.

Thermal Resistance and Dimensional Stability

Epoxy laminates excel in their ability to maintain dimensional stability across a wide range of temperatures. This thermal resistance is particularly crucial in industrial automation equipment, where components may be exposed to fluctuating temperatures and thermal cycling. The low coefficient of thermal expansion exhibited by epoxy laminates minimizes warpage and distortion, ensuring that critical components remain aligned and functional. Additionally, their high heat deflection temperature allows for reliable operation in elevated temperature environments, making them suitable for use in diverse industrial applications.

Applications of Epoxy Laminates in Industrial Automation

Circuit Boards and Control Panels

Epoxy laminates serve as the foundation for printed circuit boards (PCBs) and control panels in industrial automation systems. Their excellent electrical insulation properties and dimensional stability make them ideal substrates for complex electronic circuitry. These materials provide a reliable platform for mounting components, routing signals, and dissipating heat. The use of epoxy laminates in PCBs ensures signal integrity, reduces electromagnetic interference, and enhances the overall performance of automation equipment. Control panels fabricated from epoxy laminates offer durability and resistance to environmental factors, maintaining their functionality in challenging industrial settings.

Sensors and Actuators

In the realm of industrial automation, sensors and actuators play a pivotal role in data acquisition and process control. Epoxy laminates find extensive use in the construction of these critical components. The materials' combination of electrical insulation, mechanical strength, and thermal stability makes them ideal for housing sensitive sensor elements and actuator mechanisms. Epoxy laminates provide a protective barrier against electromagnetic interference, vibrations, and thermal fluctuations, ensuring accurate and reliable sensor readings. Additionally, their dimensional stability contributes to the precise positioning and movement of actuator components, enhancing the overall accuracy and repeatability of automated processes.

Enclosures and Structural Components

Epoxy laminates play a crucial role in the fabrication of enclosures and structural components for industrial automation equipment. Their high strength-to-weight ratio makes them an attractive option for creating lightweight yet durable housings for various automation devices. These materials offer excellent resistance to corrosion, chemicals, and moisture, ensuring the longevity of equipment in harsh industrial environments. Epoxy laminates can be easily machined and formed into complex shapes, allowing for the creation of custom enclosures that provide optimal protection and functionality. The use of these materials in structural components contributes to the overall robustness and reliability of automation systems, reducing the risk of equipment failure and downtime.

Advancements and Future Trends in Epoxy Laminates for Industrial Automation

Enhanced Thermal Management

As industrial automation equipment becomes increasingly sophisticated and compact, the need for effective thermal management has grown. Recent advancements in epoxy laminate technology have focused on improving thermal conductivity while maintaining excellent electrical insulation properties. Novel formulations incorporating thermally conductive fillers and engineered structures are being developed to enhance heat dissipation in high-power applications. These innovations allow for more efficient cooling of electronic components, reducing the risk of thermal-related failures and enabling higher performance in automation systems. The ongoing research in this area promises to push the boundaries of what is possible in terms of power density and reliability in industrial automation equipment.

Integration of Smart Materials

The future of epoxy laminates in industrial automation is poised for a revolutionary shift with the integration of smart materials. Researchers are exploring the incorporation of piezoelectric, shape memory, and self-healing properties into epoxy laminate composites. These advancements could lead to the development of automation equipment with built-in sensing capabilities, adaptive structures, and self-repair mechanisms. For instance, piezoelectric-infused epoxy laminates could enable real-time structural health monitoring, while self-healing properties could address micro-cracks and extend the lifespan of critical components. The integration of smart materials into epoxy laminates has the potential to create a new generation of responsive and resilient automation equipment, capable of adapting to changing environmental conditions and operational demands.

Sustainability and Environmental Considerations

As industries worldwide prioritize sustainability, the development of eco-friendly epoxy laminates for industrial automation is gaining momentum. Researchers and manufacturers are exploring bio-based epoxy resins derived from renewable resources, such as plant oils and lignin. These sustainable alternatives aim to reduce the carbon footprint associated with traditional petroleum-based epoxy laminates while maintaining or even improving performance characteristics. Additionally, efforts are being made to enhance the recyclability and end-of-life management of epoxy laminate components in automation equipment. The focus on sustainability extends to the manufacturing processes as well, with innovations in low-energy curing techniques and solvent-free production methods. These advancements in eco-friendly epoxy laminates are poised to play a crucial role in the development of more sustainable and environmentally responsible industrial automation solutions.

Conclusion

Epoxy laminates have emerged as indispensable materials in the realm of industrial automation equipment, offering a unique combination of electrical insulation, mechanical strength, and thermal stability. Their versatility and reliability have made them essential components in circuit boards, sensors, actuators, and structural elements of automated systems. As the field of industrial automation continues to evolve, epoxy laminates are poised to play an even more significant role, with advancements in thermal management, smart material integration, and sustainability driving innovation. The ongoing development of these materials promises to enhance the performance, efficiency, and environmental footprint of industrial automation equipment, paving the way for more sophisticated and sustainable manufacturing processes.

Contact Us

For more information about our high-quality epoxy laminates and how they can benefit your industrial automation equipment, please don't hesitate to reach out to us. Contact our team of experts at info@jhd-material.com to discuss your specific needs and discover how our products can enhance your automation systems.