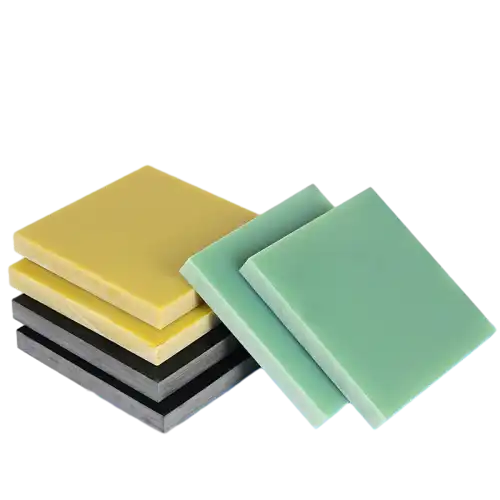

Mechanical Properties of G10 Material

Tensile Strength and Modulus

G10 material exhibits exceptional tensile strength, generally ranging from 275 to 300 MPa, which allows it to endure substantial pulling forces without breaking. This makes G10 highly suitable for structural components in mechanical assemblies. Its tensile modulus, typically between 17 and 19 GPa, indicates a high degree of stiffness, ensuring minimal elongation under stress. These mechanical traits enable G10 to perform reliably in load-bearing roles where both strength and rigidity are critical, even under prolonged or repeated stress conditions.

Compressive Strength

The compressive strength of G10 is a key factor in its performance under heavy loads, often exceeding 410 MPa. This means the material can withstand significant pressure without collapsing or deforming, which is vital in mechanical and electrical applications requiring dimensional stability. G10 maintains its shape and strength under compression, making it ideal for spacers, washers, and insulating parts in high-pressure environments. Its durability under crushing forces extends its service life and minimizes maintenance needs in critical systems.

Impact Resistance

G10 epoxy sheets demonstrate excellent impact resistance, with typical Izod impact strength values ranging from 65 to 80 kJ/m². This makes them capable of absorbing sudden shocks and blows without cracking or failing, which is essential in dynamic environments. Whether used in electronics, aerospace, or industrial applications, G10 provides long-lasting protection and performance. Its ability to resist damage from mechanical impacts helps maintain structural integrity, making it a preferred choice for components exposed to vibration, movement, or harsh operating conditions.

Electrical Properties of G10 Material

Dielectric Strength

One of the most notable electrical properties of G10 material is its high dielectric strength, which can exceed 20 kV/mm. This exceptional insulating capability makes G10 sheets an ideal choice for electrical and electronic applications where preventing current flow between conductive components is crucial. The material's ability to withstand high voltages without breakdown contributes to its widespread use in circuit boards, insulators, and high-voltage equipment.

Volume Resistivity

G10 material exhibits impressive volume resistivity, typically in the range of 10^14 to 10^16 ohm-cm. This high resistance to electrical current flow through the bulk of the material ensures minimal power loss and excellent insulation performance. The high volume resistivity of G10 sheets makes them suitable for applications requiring precise control of electrical current paths and minimal interference between components.

Arc Resistance

G10 epoxy sheets demonstrate superior arc resistance, with values often exceeding 120 seconds. This property is crucial in high-voltage applications where electrical arcing can occur. The material's ability to resist degradation from electrical arcs helps maintain the integrity of electrical systems and prolongs the lifespan of components made from G10 material.

Thermal and Environmental Properties of G10 Material

Temperature Resistance

G10 material exhibits excellent temperature resistance, maintaining its properties over a wide range of temperatures. The continuous operating temperature for G10 sheets typically ranges from -65°C to 130°C, with short-term exposure capabilities up to 180°C. This thermal stability ensures reliable performance in applications subject to temperature fluctuations or extreme heat, making G10 epoxy sheets suitable for use in aerospace, automotive, and industrial environments.

Moisture Absorption

One of the key advantages of G10 material is its low moisture absorption rate, typically less than 0.1% over 24 hours. This property is crucial for maintaining dimensional stability and electrical properties in humid or wet environments. The resistance to moisture absorption helps prevent swelling, warping, or degradation of the material's mechanical and electrical characteristics, ensuring consistent performance in diverse applications.

Chemical Resistance

G10 sheets demonstrate excellent resistance to a wide range of chemicals, including oils, fuels, and many solvents. This chemical inertness makes G10 material suitable for use in corrosive environments or applications where exposure to harsh chemicals is expected. The material's ability to maintain its properties in the presence of various chemical agents contributes to its longevity and reliability in industrial and marine applications.

Conclusion

The exceptional properties of G10 material make it an invaluable resource in engineering applications across various industries. Its unique combination of high mechanical strength, superior electrical insulation, and excellent thermal and environmental resistance positions G10 sheets and G10 epoxy sheets as preferred choices for demanding applications. From aerospace components to electrical insulators and structural elements in harsh environments, G10 material continues to prove its worth in modern engineering. As technology advances and new challenges emerge, the versatility and reliability of G10 material ensure its continued relevance in innovative engineering solutions.

Contact Us

For more information about our G10 sheets and G10 epoxy sheets, or to discuss how our products can meet your specific engineering needs, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your application.