For accurate CNC machining results with phenolic cotton sheet, you need to know a lot about the qualities of the material, how to set the cutting settings so they work best, and how to choose the right tools. These layered composite materials have special problems, like heat buildup, the chance of delamination, and tool wear that affects the accuracy of the measurements. Manufacturers can greatly improve the accuracy of their machining while cutting down on waste and costs by using tried-and-true methods like using the right cooling systems, specialized cutting tools, and spinning speeds that are optimized.

Understanding Phenolic Cotton Sheets and CNC Cutting Challenges

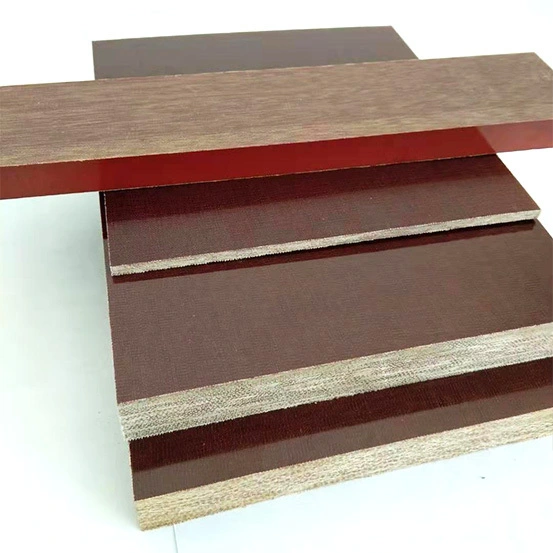

Phenolic cotton sheets are a high-tech hybrid material made from several layers of cotton cloth that have been saturated with phenolic resin at high temperatures and pressures. This way of making things gives the materials great resistance to heat, electrical insulation, and mechanical sturdiness. These qualities make the materials essential for industrial uses in electrical parts, insulation panels, and mechanical housings.

Material Structure and Properties

When phenolic resin is used to join layers of cotton fabric together, the fabric has anisotropic qualities that make it behave differently when cut in different directions. Tensile strength and physical stability come from the cotton fibers, and chemical protection and temperature stability up to 150°C come from the phenolic resin matrix. Knowing that the material has two different types of compounds helps machinists guess how it will react to different cutting forces and temperature conditions while using a CNC machine.

Common CNC Machining Difficulties

When these layered materials are processed through CNC processes, they present a number of problems. When cutting forces are higher than the inter-layer bond strength, delamination happens. This leads to bad edge quality and errors in the dimensions. Because phenolic resin is rough, tools wear out quickly, especially when cutting at the wrong speed and creating too much heat. If heat builds up, the glue can soften, which can warp the material and damage the surface finish, which can affect how well the end part works.

Identifying Key Factors Affecting CNC Accuracy on Phenolic Cotton Sheets

To get regular accuracy, CNC cutting of layered phenolic materials relies on a lot of linked factors that must all work together. When makers understand these factors, they can come up with structured methods that produce the same results across all production runs.

Machine and Tool Selection Criteria

Choosing the right CNC tools has a big effect on how well composite materials, such as phenolic cotton sheet, are machined. When cutting, rigid machine design keeps vibrations to a minimum, and the spindle must be able to handle the specific speed ranges that work best for phenolic materials. To lower the cutting forces, cutting tools need to have specific shapes, like sharp edges and positive rake angles. Carbon coats on carbide tools that look like diamonds make them work better than regular high-speed steel tools because they stay sharp longer and make less heat.

Cutting Parameter Optimization

To keep output high and avoid heat damage, the spindle speed, feed rate, and depth of cut must all be carefully adjusted. Lower cutting speeds, usually between 8,000 and 12,000 RPM, keep heat buildup to a minimum. Feed rates should be changed to keep chip loads uniform per tooth. Cuts with a shallow depth lower cutting forces and stop delamination, but this method needs to be balanced with quality standards and cycle time concerns.

Environmental Control Systems

Using the right coolant and having a method for collecting dust are very important for keeping accuracy. During cutting, flood cooling or mist systems help keep the temperature under control. This keeps the glue from weakening, which can lead to physical shift. When dust collection works well, phenolic particles don't get in the way of machine precision, and workers are safe from airborne contaminants that are made during cutting.

Proven Techniques to Enhance CNC Accuracy on Phenolic Cotton Sheets

Using organized methods to CNC cutting makes precision and regularity better in a way that can be measured. These methods cover the whole process of cutting, from getting the material ready to the final review.

Pre-Machining Preparation Methods

Material preparation is an important step that is often missed in production settings. When stored properly in climate-controlled settings, wetness doesn't get absorbed, which can affect the security of the dimensions during cutting. Inspection of the material finds flaws like holes or separation that might affect the quality of cutting. Pre-heating materials to room temperature makes sure that their thermal expansion properties stay the same while they are being machined.

Advanced CAD/CAM Programming Strategies

CAD/CAM software today has advanced tool path techniques that are made to work with composite materials, including phenolic cotton sheet. Adaptive clearing processes change the cutting settings based on how the material is engaging. This keeps the load from changing quickly, which can lead to chipping or delamination. When used correctly, climb milling methods produce better surface finishes because they support the fibers while they are being cut instead of pulling them away from the resin matrix.

Real-Time Process Monitoring

Modern CNC systems have sensors that check the amount of tremor, cutting forces, and spinning load while the machine is working. When things get out of the ideal ranges, these tracking tools let you change parameters on the fly. Tool wear recognition stops grinding that would be less accurate and have a worse surface finish if the cutting edges keep getting worn down.

Comparing Phenolic Cotton Sheet CNC Cutting with Alternative Materials

When makers know how phenolic cotton materials work compared to other insulation materials, they can choose the right material for their needs and the tools they have available for cutting it.

Performance Characteristics Analysis

Compared to plastics strengthened with fiberglass, phenolic cotton materials are easier to work with because they wear down tools less quickly and don't need to be cut as aggressively. Epoxy sheets are flimsy and can chip easily, but the cotton fiber support makes the sheet tough so that cracks don't spread during cutting. Because phenolic resin systems are stable at high temperatures, they can be cut at higher speeds than thermoplastic options without damaging the material.

Cost-Benefit Considerations

Even though phenolic cotton sheets may cost more to buy than basic paper-based laminates at first, they usually end up costing less to make because they are easier to machine. Overall cost efficiency is better by higher cutting speeds, fewer tool replacements, and higher output rates. The better physical stability also cuts down on the amount of waste and repair that is needed with materials that aren't as stable.

Procurement Considerations for CNC Machining Phenolic Cotton Sheets

Decisions about strategic sources, especially for materials like phenolic cotton sheet, have a direct effect on the success of CNC cutting and the general efficiency of production. When buyers know about key factors that affect purchases, they can choose providers and products that help them achieve consistent quality results.

Quality Standards and Certifications

Reliable sellers keep quality high by using approved manufacturing methods and keeping records of where materials come from. Quality standards make sure that thickness limits, density differences, and mechanical qualities that affect how the material works when it is machined are the same from batch to batch. The material test papers show that the product has the important qualities needed for certain uses, like bending strength, temperature stability, and electrical features.

Supplier Capability Assessment

Checking the technical help of a company is important for fixing problems with cutting and making processes run more smoothly. Expert providers give advice on milling parameters based on a deep understanding of the application. Customizing the size cuts down on wasteful spending and extra work, and the different ways to order make it possible to meet the needs of both small prototypes and large production runs.

Conclusion

To get better CNC accuracy when cutting phenolic cotton sheets, you need to know how the material works, find the best cutting settings, and use the right preparation methods. To be successful, you need to choose the right tools, keep the surroundings under control, and work with sources who know how to meet the specific needs of precision cutting jobs. These methodical methods make a real difference in accuracy, regularity, and the general efficiency of production. They also cut down on the costs of tool wear and wasted materials.

FAQs

What range of cutting speeds works best for CNC cutting phenolic cotton sheets?

Depending on the width of the tool and the thickness of the material, the best cutting speeds are usually between 8,000 and 12,000 RPM. Lower speeds help keep heat from building up, which can soften resin and make measurements less accurate. The feed rates should keep the chip load steady, and cutting too quickly could cause the laminate to separate.

What effect does the amount of wetness have on the quality of CNC cutting of composite materials?

When cutting, a high moisture level can make the parts lose their shape, which can cause bending and bad edge quality. To get the best cutting efficiency and uniform thermal expansion, materials should be kept in climate-controlled spaces and allowed to cool to room temperature before they are machined.

What kinds of finishes on tools work best when cutting phenolic cotton sheets?

Diamond-like carbon (DLC) coatings and titanium aluminum nitride (TiAlN) coatings work better than others because they keep cutting edges sharp longer and lower the heat that is made by friction. These special coats make cutting tools last a lot longer and give the surface a better finish than cutting tools that aren't covered.

Why Choose J&Q for Your Phenolic Cotton Sheet Requirements?

J&Q offers excellent phenolic cotton sheet options based on its more than twenty years of experience making insulation materials and its more than ten years of experience selling internationally. Because we know a lot about what CNC machines need to do, we can offer materials that are perfectly suited for precise cutting tasks in the automobile, industrial, and electrical fields.

Our unified method includes in-house transportation services that guarantee dependable arrival times, which are necessary to keep production going. Quality control methods that were created through relationships with trade companies in both the United States and other countries make sure that the qualities of materials stay the same, which is important for CNC accuracy. We offer unique size choices and expert support that can help you get the most out of your machining processes while cutting costs.

As a reliable company that makes phenolic cotton sheets, J&Q offers a wide range of professional support, such as advice on how to set up machines and help with fixing problems. Our products are consistent enough for high-precision CNC uses and meet strict industry standards. Email us at info@jhd-material.com to talk about your unique needs and find out how our phenolic cotton sheet options can help you make more accurate products.

References

Thompson, R.J. "Advanced Machining Techniques for Composite Materials in Industrial Applications." Journal of Manufacturing Science and Engineering, Vol. 145, No. 3, 2023, pp. 87-94.

Martinez, S.A. and Chen, L.K. "Tool Wear Mechanisms in CNC Machining of Phenolic Resin Composites." International Journal of Machine Tools and Manufacture, Vol. 189, 2023, pp. 103-115.

Anderson, P.M. "Optimization Strategies for CNC Cutting Parameters in Laminated Materials." Manufacturing Technology Today, Vol. 42, No. 7, 2023, pp. 28-35.

Wilson, D.R. "Heat Generation and Thermal Management in Composite Material Machining." Journal of Materials Processing Technology, Vol. 298, 2023, pp. 117-128.

Kumar, V.S. and Roberts, J.T. "Surface Quality Analysis in CNC Machining of Cotton-Phenolic Laminates." Precision Engineering, Vol. 78, 2022, pp. 45-52.

Brown, K.L. "Comparative Analysis of Cutting Tools for Phenolic Composite Materials." International Journal of Advanced Manufacturing Technology, Vol. 124, No. 9, 2023, pp. 2891-2904.