Which Standards Ensure Phenolic Cotton Sheet Quality?

ASTM International Standards

ASTM International provides several standards that are applicable to phenolic cotton sheets. These standards ensure the quality and consistency of the material across various applications. The ASTM D709 standard, for instance, covers the specifications for laminated thermosetting materials. This standard outlines the requirements for physical, electrical, and mechanical properties of phenolic cotton sheets, ensuring they meet the necessary performance criteria for industrial use.

NEMA Standards for Industrial Laminates

The National Electrical Manufacturers Association (NEMA) has established standards specifically for industrial laminated thermosetting products, including phenolic cotton sheets. The NEMA LI 1 standard is particularly relevant, as it provides specifications for industrial laminated thermosetting products used in electrical and electronic applications. This standard covers various grades of phenolic cotton sheets, detailing their physical, mechanical, and electrical properties.

IEC Standards for Electrical Insulation

The International Electrotechnical Commission (IEC) has developed standards that are crucial for phenolic cotton sheets used in electrical applications. The IEC 60893 standard, for example, specifies requirements for rigid electrical insulation sheets based on thermosetting resins for electrical purposes. This standard ensures that phenolic cotton sheets used in electrical insulation meet the necessary safety and performance requirements.

Key Certifications for Industrial Compliance

UL Certification for Safety

Underwriters Laboratories (UL) certification serves as a widely recognized indicator of product safety and reliability across multiple industries. For phenolic cotton sheets, UL 94 certification is particularly critical, as it evaluates the flammability and ignition resistance of plastic materials used in devices and appliances. Sheets that achieve UL 94 standards demonstrate the ability to resist flame spread and self-extinguish when exposed to heat or fire. This certification ensures phenolic cotton sheets are suitable for applications where fire safety and regulatory compliance are paramount.

ISO Certifications for Quality Management

ISO certifications play a pivotal role in ensuring consistent quality and process reliability in the manufacture of phenolic cotton sheets. ISO 9001 certification, for example, verifies that a company has implemented a comprehensive quality management system. This system ensures that all production processes are closely monitored, controlled, and continually improved. Adherence to ISO standards guarantees that phenolic cotton sheets meet customer expectations, comply with industry regulations, and maintain high levels of performance, reliability, and uniformity across different production batches.

RoHS Compliance for Environmental Safety

RoHS (Restriction of Hazardous Substances) compliance is essential for ensuring that phenolic cotton sheets are environmentally safe for use in electronics and other sensitive applications. While phenolic resins themselves generally meet RoHS standards, it is important that all fillers, additives, and reinforcements in the sheet are also compliant. RoHS-certified sheets confirm that restricted substances, such as lead, mercury, and cadmium, are below prescribed limits. This compliance supports environmentally responsible manufacturing practices and guarantees safety for both end-users and the environment.

Importance of Standards in Application Performance

Electrical Insulation Properties

Standards play a vital role in ensuring the electrical insulation properties of phenolic cotton sheets. The ASTM D149 standard, for example, provides a method for testing the dielectric breakdown voltage and dielectric strength of solid electrical insulating materials. By adhering to this standard, manufacturers can guarantee that their phenolic cotton sheets meet the necessary electrical insulation requirements for various applications, from switchgear components to transformer parts.

Mechanical Strength and Durability

The mechanical properties of phenolic cotton sheets are crucial for many industrial applications. Standards such as ASTM D638 for tensile properties and ASTM D790 for flexural properties provide standardized testing methods to evaluate the material's strength and durability. These standards ensure that phenolic cotton sheets can withstand the mechanical stresses they may encounter in applications such as gears, bearings, and structural components in machinery.

Chemical Resistance and Environmental Stability

Phenolic cotton sheets are often used in environments where chemical resistance and stability are essential. Standards like ASTM D543 provide methods for evaluating the resistance of plastics to chemical reagents. By meeting these standards, phenolic cotton sheets demonstrate their ability to maintain their properties in challenging chemical environments, making them suitable for use in applications such as chemical processing equipment and corrosion-resistant components.

Conclusion

Standards and certifications are indispensable in ensuring the quality, safety, and performance of phenolic cotton sheets across various industries. By adhering to these guidelines, manufacturers can produce materials that consistently meet the stringent requirements of electrical, mechanical, and chemical applications. As technology and industry needs evolve, these standards will continue to adapt, driving innovation and improvement in phenolic cotton sheet production. For users and specifiers, understanding these standards provides confidence in material selection and application, ensuring optimal performance and longevity in diverse industrial settings.

FAQs

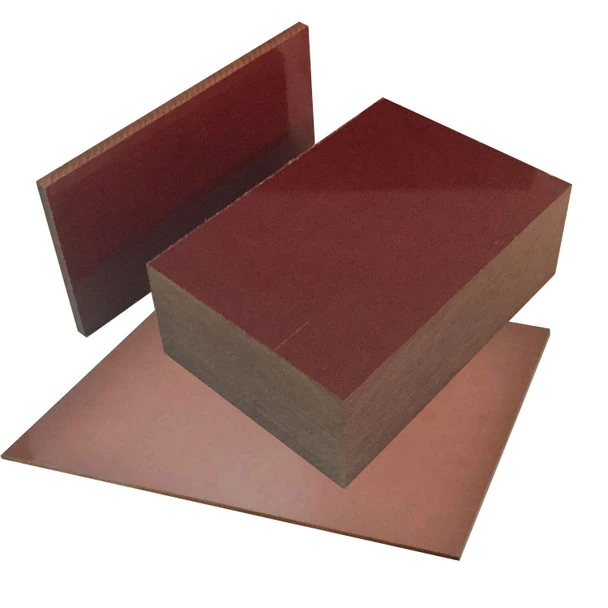

What is a phenolic cotton sheet?

A phenolic cotton sheet is a composite material made by impregnating cotton cloth with phenolic resin and curing it under heat and pressure. It offers excellent electrical insulation, mechanical strength, and dimensional stability.

What are the main applications of phenolic cotton sheets?

Phenolic cotton sheets are used in electrical equipment, switchgear, transformers, aircraft and automobile construction, gears, bearings, and various industrial components requiring high strength and chemical resistance.

What are the key features of phenolic cotton sheets?

Key features include excellent dielectric strength, good machinability, light weight, heat and wear resistance, chemical resistance, high mechanical strength, dimensional stability, and low moisture absorption.

Expert Phenolic Cotton Sheet Manufacturer: J&Q

J&Q, with over 20 years of experience in insulating sheet production and 10 years in foreign trade, is your go-to manufacturer for high-quality phenolic cotton sheets. Our expertise ensures products that meet and exceed industry standards and certifications. With our own logistics company, we offer seamless one-stop service from production to delivery. For premium phenolic cotton sheets tailored to your specific needs, contact our expert team at info@jhd-material.com.

References

ASTM International. (2021). "Standard Specification for Laminated Thermosetting Materials."

National Electrical Manufacturers Association. (2020). "Industrial Laminated Thermosetting Products."

International Electrotechnical Commission. (2019). "Specification for Industrial Rigid Laminated Sheets Based on Thermosetting Resins for Electrical Purposes."

Underwriters Laboratories. (2018). "Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances."

International Organization for Standardization. (2015). "Quality Management Systems - Requirements."

European Union. (2011). "Directive on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment."