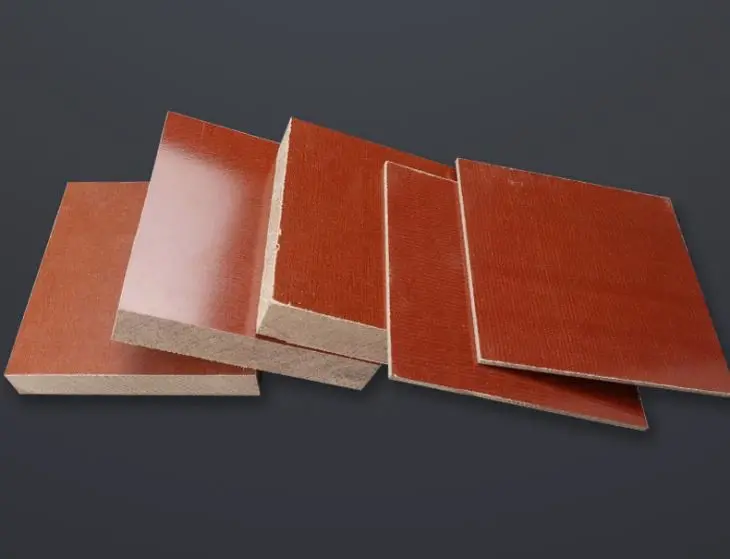

Phenolic Cotton Sheets: Comprehensive Product Knowledge

Phenolic cotton sheets, also known as phenolic cotton cloth boards, are advanced insulating materials that combine the strength of phenolic resin with the flexibility of cotton fabric. These versatile sheets offer exceptional electrical insulation, mechanical strength, and thermal resistance, making them indispensable in various industrial applications. From electrical equipment to automotive components, phenolic cotton sheets provide reliable performance in demanding environments. This comprehensive guide delves into the properties, manufacturing process, and applications of phenolic cotton sheets, equipping you with the knowledge to make informed decisions for your insulation needs.

Understanding Phenolic Cotton Sheets: Composition and Properties

Chemical Composition and Structure

Phenolic cotton sheets are engineered by combining layers of woven cotton fabric with phenolic resin under heat and pressure. The cotton fabric acts as a reinforcing substrate, giving the sheet its structural integrity and impact resistance. Meanwhile, the phenolic resin permeates the cotton layers, bonding them into a solid, cohesive laminate. This resin not only binds the fibers together but also imparts excellent insulating and chemical-resistant properties. The resulting structure is strong, dimensionally stable, and capable of withstanding mechanical and thermal stress.

Key Physical Properties

Phenolic cotton cloth board possesses a range of physical properties that make it ideal for mechanical and electrical applications. Its high tensile and compressive strength enable it to endure heavy loads and repetitive stress without deformation. It also maintains excellent dimensional stability, resisting warping under temperature or humidity fluctuations. Low water absorption ensures reliable performance in humid environments, while its density of approximately 1.2-1.4 g/cm³ reflects a balance between strength and manageable weight. These properties collectively support the use of phenolic cotton cloth board as a durable structural and insulating component.

Electrical and Thermal Characteristics

The electrical and thermal performance of phenolic cotton sheets is among their most advantageous attributes. With high dielectric strength and low dielectric constant, they effectively prevent electrical leakage and maintain insulation even under high voltages. Their arc resistance ensures safety in electrical assemblies where exposure to sparks or current surges is possible. Thermally, they can withstand continuous operating temperatures up to 130°C (266°F), with brief exposure tolerating even higher temperatures without losing integrity. These characteristics make them reliable materials in electrical equipment, transformers, and thermal insulation applications.

Manufacturing Process and Quality Control

Raw Material Selection and Preparation

The production of phenolic cotton sheets starts with sourcing high-grade cotton fabric that possesses uniform weave density and strong tensile properties. This fabric undergoes cleaning to eliminate oils, waxes, and contaminants that could interfere with resin bonding. Concurrently, phenolic resin is formulated to achieve precise viscosity, reactivity, and curing profiles required for optimal impregnation. These steps are essential to produce high-quality phenolic cotton cloth board with strict specifications followed during material selection to ensure consistent performance, mechanical strength, and insulation quality in the final product, laying a solid foundation for subsequent manufacturing stages.

Impregnation and Layering Techniques

Impregnation involves saturating the pre-treated cotton fabric with the prepared phenolic resin under controlled conditions. Modern techniques utilize rollers, vacuum, or pressure impregnation systems to guarantee deep resin penetration, complete fiber wetting, and uniform resin distribution. This ensures the elimination of voids and air bubbles that could compromise structural integrity. After impregnation, individual resin-soaked sheets are layered in specific orientations to achieve the required thickness, mechanical strength, and dimensional stability. Precise alignment during layering is critical to maintaining uniformity across the entire phenolic cotton sheet.

Curing and Finishing Procedures

Following the layering process, the stacked impregnated fabrics are placed into a heated press or curing oven under specific temperatures and pressures. During curing, the phenolic resin undergoes polymerization, bonding firmly with cotton fibers to form a hard, stable laminate with excellent mechanical and electrical properties. Controlled curing schedules are essential to avoid internal stresses or incomplete curing. Post-curing, the sheets are cooled, trimmed to standard dimensions, and polished for smoothness. Rigorous quality control inspections assess thickness, density, mechanical strength, and electrical insulation before release to ensure compliance with all specifications.

Applications and Industry-Specific Uses

Electrical and Electronics Industry

Phenolic cotton sheets, also known as phenolic cotton cloth board, are widely utilized in the electrical and electronics industry due to their outstanding insulating capabilities and mechanical strength. They are frequently used in the manufacturing of switchgear panels, transformer insulation supports, coil forms, and circuit board substrates. Their high dielectric strength ensures they can withstand elevated voltages without electrical breakdown, ensuring equipment safety. Additionally, their excellent arc resistance and thermal stability make them reliable for continuous use in electrical assemblies, preventing malfunctions and extending the lifespan of critical electrical infrastructure components.

Automotive and Transportation Sector

Within the automotive and transportation sector, phenolic cotton sheets are valued for their durability, heat resistance, and oil tolerance. They are incorporated into various vehicle components such as gaskets, seals, clutch facings, and thermal insulation barriers around engines and electrical systems. Their ability to maintain structural integrity under high mechanical stress and elevated temperatures ensures long-lasting performance. Furthermore, their resistance to fuels, lubricants, and chemical exposure enhances safety and reduces maintenance needs, supporting the reliability of modern vehicles, heavy-duty trucks, and rail transportation systems.

Industrial Machinery and Equipment

Phenolic cotton sheets serve as integral components in industrial machinery due to their robust mechanical and insulating properties. They are often fabricated into gear wheels, bearings, structural spacers, and insulating supports within electrical motor assemblies. Their low friction coefficient and resistance to abrasion enable smooth operation in moving parts, reducing wear and extending service life. Additionally, their thermal stability and dimensional consistency under operational loads make them a preferred choice in heavy machinery, power tools, and precision equipment, ensuring reliable performance even under demanding industrial conditions.

Conclusion

Phenolic cotton sheets represent a pinnacle of insulation technology, offering a unique blend of electrical, thermal, and mechanical properties. Their versatility and reliability make them indispensable in numerous industries, from electrical manufacturing to automotive engineering. As technology continues to advance, the demand for high-performance insulating materials like phenolic cotton sheets is expected to grow. Understanding the composition, manufacturing process, and applications of these sheets is crucial for engineers, designers, and industry professionals seeking optimal solutions for their insulation needs.

Contact Us

For more information about our range of phenolic cotton sheets and how they can benefit your specific application, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect insulation solution for your project. Reach out to us at info@jhd-material.com to discuss your requirements and discover how our products can enhance your operations.

References

Johnson, R. T. (2020). Advanced Insulation Materials: A Comprehensive Guide. Industrial Press.

Smith, A. L., & Brown, C. D. (2019). Phenolic Resins: Chemistry, Applications and Performance. Elsevier Science.

Lee, S. M. (2021). Handbook of Composite Reinforcements. Wiley-VCH.

Parker, E. R. (2018). Materials for Electrical Insulation and Dielectrics. Springer.

Thompson, K. L. (2022). Innovations in Automotive Materials and Manufacturing. SAE International.

Zhang, Y., & Liu, X. (2020). Advanced Manufacturing Processes for Polymer Matrix Composites. Woodhead Publishing.

Get a complete product list and quotation

J&Q New Composite Materials Company