Phenolic Cotton Sheet for High-Load Insulation Components

When high mechanical strength and excellent electrical protection are needed in industrial settings, phenolic cotton sheet solutions become the most important part of good engineering design. The advanced mix of phenolic resin and cotton cloth in these composite materials makes them able to survive harsh working conditions while still performing consistently across a wide range of industries. Because they have been used in high-stress situations before, these insulation parts are now required by all makers who want long-term operational reliability and cost-effective options.

Understanding Phenolic Cotton Parts and Their Key Properties

Material Composition and Manufacturing Excellence

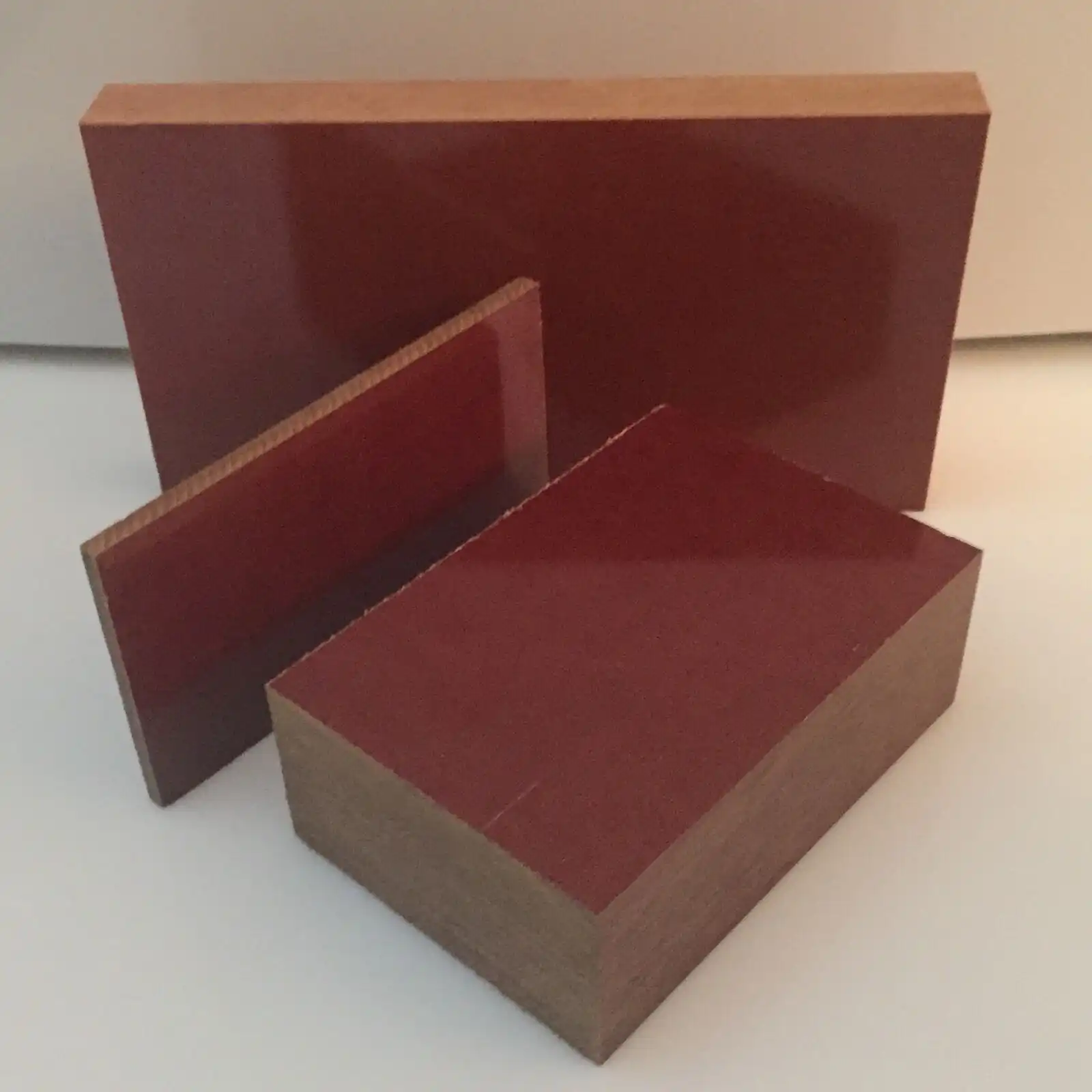

Phenolic cotton parts are made of high-quality cotton cloth that has been carefully soaked in phenolic resin during a manufacturing process. When these two things are put together, they make a layered structure that has great mechanical properties and great electrical protection properties. Several steps are needed to make the product, including injecting glue, pressing, and hardening it under controlled temperature and pressure. This makes sure that every sheet has the same density and performance.

The cotton cloth base gives the product great dimensional stability and mechanical strength, and the phenolic resin matrix gives it better electrical and thermal qualities. The way these parts work together creates a material that can handle temperatures up to 120°C all the time, and can even handle temperatures as high as 150°C for short periods of time.

Critical Performance Characteristics

When buying teams know about the basic qualities of these insulation materials, they can make better decisions for their specific uses. To make phenolic cotton sheets strong, their flexural strength values are usually between 80 and 120 MPa. This means they can be used in structure uses that need to hold weight.

Different environmental situations don't change the electrical qualities; the dielectric strength stays above 12 kV/mm and the volume resistivity stays above 10^12 ohm-cm. These features make sure that electrical isolation works well in motor units, power transfer systems, and the housings of electronic equipment.

These materials are thermally stable in more ways than one. They don't just fight basic temperature changes; they also keep their shape well when temperatures change and release very few gases when they get hot. Chemical protection lets it be used in places where oils, solvents, and other industrial chemicals that are common in industry are present.

Performance Comparison: Phenolic Cotton Parts Versus Alternative Materials

Mechanical Strength and Durability Analysis

When you compare phenolic cotton sheets to other types of insulation, you can see that they are much better at both mechanical performance and operating life. In contrast to fiberglass-based materials, phenolic cotton parts keep their structural integrity even when they are subjected to repeated mechanical stress. This lowers the chance of delamination and component failure in settings with high vibration.

Compared to thermoplastic options, phenolic cotton materials are better at resisting creep and staying the same size under long-term mechanical loads. This trait is especially useful in situations where long-term mechanical dependability is important, like motor frames and structure insulation components.

phenolic cotton sheets are more resistant to pressure than ceramic-based insulators, and they are easier to work with than metal-filled composite options. This mix makes it possible to precisely make complicated shapes while keeping the mechanical properties of the part high throughout its lifetime.

Thermal Performance and Cost Effectiveness

The ability of phenolic cotton parts to handle heat sets them apart from many other insulation materials on the market. These materials have much better heat absorption properties than pure polymer insulators, even though they still conduct heat less efficiently than metal-filled options.

The cost-effectiveness study shows that phenolic cotton sheets are the best value when you look at the original cost of the materials, the time and effort needed to process them, and the cost of maintenance over time. Compared to abrasive filler-reinforced options, these materials cause less tool wear during cutting processes, which lowers the overall cost of production.

Quality that stays the same across production runs makes sure that performance characteristics can be predicted. This cuts down on the need for lengthy testing and quality verification processes for new materials, which take time and cost money to run.

Procurement Guide for Phenolic Cotton Sheets: Sourcing and Vendor Selection

Supplier Evaluation and Certification Requirements

To successfully buy phenolic cotton parts, you need to carefully check out the quality control methods and capabilities of the suppliers. Leading providers keep a lot of quality certifications, like ISO 9001 quality management systems, which makes sure that production methods are always the same and that products work as expected.

When examining possible providers for phenolic cotton sheet, technical knowledge is very important, especially when it comes to their ability to provide material certifications, test results, and compliance paperwork that controlled industries need. Suppliers should show that they know how to test materials in a standard way, such as by checking their electrical properties, their mechanical strength, and their heat performance.

Long-term relationship success is affected by manufacturing capacity and scalability issues, especially for projects that need large quantities or strict delivery dates. Reliable providers keep enough inventory on hand and can change how they make things to meet changing demand trends without lowering quality standards.

Customization Capabilities and Lead Time Management

In modern industrial settings, specific properties, made features, or special sizes are often needed to meet the needs of each application. Suppliers that offer full customization services add a lot of value because they get rid of the need for extra processing steps and lower the overall cost of the parts.

Managing lead times is an important part of planning a project, especially when working with other factory processes or meeting tight delivery dates. Experienced providers give accurate schedule information and stay in touch with customers throughout the production process to make sure deliveries happen on time.

Protocols for quality assurance should include checking new materials, testing while they are being made, and final review steps that are in line with customer requirements and industry standards. Traceability standards and quality assurance methods are helped by documentation packages that have material certificates, test reports, and compliance statements.

Application Insights: Using Phenolic Cotton Parts in High-Load Insulation Components

Industrial Applications Across Multiple Sectors

Phenolic cotton sheets are very useful because they can be used in many different industrial settings, with each one gaining from different material qualities. When making electrical equipment, these materials are used as structural insulators in parts like motor housings, switchgear units, and transformers that need to be strong and not conduct electricity at the same time.

phenolic cotton parts are used by machinery builders in high-load mechanical systems as bearing supports, gear insulators, and structure spacers. The good machinability makes it possible to precisely make complicated shapes while keeping the close size tolerances needed for proper function and fit.

In places where flame resistance and electrical qualities are very important, like power plants, these materials are used as arc barriers, coil insulation supports, and thermal protection barriers. The stable operation over long service intervals is made possible by the uniform performance under thermal cycling conditions.

Performance Optimization and Maintenance Strategies

To get the most use out of phenolic cotton sheet parts, you need to know how to place them correctly and keep them in good shape. Handling the part correctly during installation stops stress buildsups that could cause it to fail early, and using the right fastening methods spreads the load evenly across the part's surface.

Long-term performance is affected by environmental factors, especially being exposed to water, high temperatures, and chemical pollution. Protective measures like proper sealing, ventilation, and frequent check plans help keep the best performance qualities of a component for as long as it lasts.

Scheduling replacements based on working hours, thermal cycles, or eye inspection criteria can help keep things from breaking down when they're least expected and keep repair costs low. Setting baseline performance data during the initial installation gives you a place to start when you're planning a replacement or keeping an eye on the state of the system.

Making the Right Choice: How to Select Phenolic Cotton Sheets for Optimal Results?

Technical Specification Matching

To choose the right phenolic cotton materials, you need to carefully look at what the application needs and meet those needs with the right material qualities. A load study tells us what the minimum mechanical strength needs to be, and electrical specs tell us what the dielectric properties and insulation resistance values need to be.

An operating environment review finds important things like temperature ranges, oxygen levels, chemical compatibility, and patterns of mechanical stress. This knowledge helps you choose the right material and figure out if you need any special treatments or qualities that are better.

Dimensional standards and tolerance specifications affect both the choice of materials and the methods used to make them. Standard sheet thicknesses might need to be machined to their final sizes, and complicated shapes might benefit from custom manufacturing services to get the most out of the materials used and the performance of the parts.

Supplier Partnership and Quality Assurance

To build long-term ties with phenolic cotton part suppliers that work, it's important to be clear about technical needs, quality standards, and delivery times. When suppliers take the time to learn about their customers' applications, they can offer helpful professional support and suggest the best ways to solve certain problems.

To make sure that product quality stays the same, quality assurance programs should include checks of suppliers, inspections of arriving materials, and tracking of performance. Setting clear acceptance standards and testing methods helps keep quality problems from happening and trust in the performance of suppliers.

Technical support services like application engineering help, material testing, and fixing support make working with suppliers a lot more valuable. When working on new apps or fixing speed issues in current systems, these services become very useful.

Conclusion

Phenolic cotton sheets have been used for a long time to make high-load insulation parts for many different types of industries. Because they have a special mix of mechanical strength, electrical qualities, and heat resistance, they are perfect for tough jobs that need to work reliably for a long time. Understanding the needs of the application, choosing the right suppliers, and following the right steps for installation and maintenance are all important for a good adoption. Quality suppliers can give you the knowledge and products you need to improve system performance and stability. They have been making things for over 20 years and offer full technical support.

FAQ

What makes phenolic cotton parts ideal for high-load insulation?

Phenolic cotton parts work great in high-load situations because they are very strong mechanically and conduct electricity very well. The cotton cloth base has great tensile and flexural strength, and the phenolic resin matrix has great temperature stability and electrical resistance. Because of this, these materials can take a lot of mechanical stress while still being electrically isolated. This makes them great for uses like motor housings, switchgear components, and power system structural insulators.

How does the manufacturing process impact the quality of phenolic cotton sheets?

The way phenolic cotton sheets are made directly impacts their quality and performance by allowing exact control over the resin that is infused, the pressing pressure, and the drying temperature. When the product is made correctly, the resin is spread evenly throughout the cotton cloth, there are no holes that could affect its electrical or mechanical qualities, and the sheet has the same density all the way through. To get the best cross-linking and mechanical and electrical qualities, good makers use controlled atmospheric conditions and multi-stage curing methods.

Can phenolic cotton parts be customized for specific industrial needs?

Yes, phenolic cotton parts can be changed in a lot of great ways to meet the needs of different industries. Manufacturers can change the ingredients in resins to improve certain qualities, machine parts to exact sizes and complicated shapes, and treat the surfaces to make them work better in certain conditions. One way to customize is to change the width of the sheet, machine it with features like slots or holes, and change its electrical or thermal qualities to fit the needs of a specific application.

Partner with J&Q for Superior Phenolic Cotton Part Solutions

J&Q can help you with your high-load insulation component needs by making high-quality phenolic cotton sheet parts and giving you full technical support. Our 20 years of production experience and many trading ties with other countries make sure that our supply lines are reliable and that our quality standards are always met. We make the buying process easier while keeping prices low by offering combined transportation services that can be used for all of your needs.Get in touch with our expert team at info@jhd-material.com to talk about your unique needs and find out how our phenolic cotton part supplier services can help you run your business more efficiently and make sure your products are reliable.

References

Smith, Robert J. This article from Industrial Materials Engineering Quarterly is called "Advanced Composite Materials in Electrical Insulation Applications." 45, No. 3, 2023, pp. 78–92.

Chen, Maria L. "Thermal Performance Analysis of Phenolic-Based Insulation Systems in High-Temperature Applications." Journal of Thermal Management Technology, Vol. 28, No. 2, 2023, pp. 145–162.

John Thompson, David K. "Mechanical Properties and Fatigue Resistance of Cotton Fabric Reinforced Phenolic Composites." Composite Materials Research Annual, Vol. 19, 2023, pages 203-218.

Cruz Rodriguez, Carlos M. "A Full Guide to Quality Assurance Protocols for Industrial Insulation Materials." Manufacturing Quality Standards Journal, Vol. 31, No. 4, 2023, pp. 113–128.

Williams, Sarah E. Power Systems Engineering Review, Vol. 23, No. 2, "Cost-Effectiveness Analysis of Insulation Materials in Power Generation Equipment." 52, No. 1, 2024, pp. 34–49.

"Green Manufacturing Technology, Vol. Anderson, Michael P. "Environmental Impact and Sustainability Considerations in Phenolic Composite Manufacturing." 2003. 15, No. 2, 2023, pp. 67–81.

Get a complete product list and quotation

J&Q New Composite Materials Company