What Standards Define NEMA CE Sheet Compliance?

NEMA LI 1 Standard Overview

The NEMA LI 1 standard serves as the cornerstone for defining CE sheet compliance. This comprehensive guideline outlines specific requirements for industrial laminated thermosetting products, encompassing a wide range of materials including phenolic, melamine, and epoxy-based laminates. The standard meticulously details physical, electrical, and mechanical properties that CE sheets must meet or exceed to ensure consistent quality and performance across various applications.

Electrical Property Requirements

Electrical properties form a crucial aspect of NEMA CE sheet compliance. The standard stipulates minimum values for dielectric strength, insulation resistance, and arc resistance. These parameters are essential for ensuring the material's ability to withstand high voltages, prevent current leakage, and resist electrical breakdown under extreme conditions. Compliance with these electrical requirements guarantees the sheet's suitability for use in diverse electrical insulation applications.

Mechanical and Physical Property Specifications

NEMA CE sheets must adhere to strict mechanical and physical property specifications. These include flexural strength, tensile strength, compressive strength, and impact resistance. Additionally, the standard outlines requirements for dimensional stability, water absorption, and flammability ratings. By meeting these specifications, NEMA CE sheets demonstrate their ability to withstand mechanical stresses, maintain structural integrity, and perform reliably in various environmental conditions.

Manufacturing Processes Ensuring Consistent Quality

Raw Material Selection and Preparation

The journey to producing high-quality NEMA CE sheets begins with meticulous raw material selection. Manufacturers source premium-grade resins, reinforcing fabrics, and additives to ensure the final product meets NEMA standards. The preparation process involves precise mixing of components, with stringent quality control measures implemented at each stage. This attention to detail in raw material handling lays the foundation for consistent sheet properties and performance.

Lamination and Curing Techniques

Advanced lamination and curing techniques play a pivotal role in achieving NEMA CE sheet compliance. State-of-the-art presses apply controlled pressure and temperature to multiple layers of resin-impregnated fabric. The curing process is carefully monitored to ensure optimal cross-linking of the thermoset resins, resulting in sheets with superior mechanical and electrical properties. Manufacturers employ sophisticated process control systems to maintain consistent curing conditions, guaranteeing uniformity across production batches.

Quality Control and Testing Procedures

Rigorous quality control and testing procedures are integral to maintaining NEMA CE sheet compliance. Manufacturers implement comprehensive in-process inspections and post-production testing protocols. These include dimensional checks, non-destructive evaluations, and a battery of standardized tests to verify electrical, mechanical, and physical properties. Advanced testing equipment and meticulously calibrated instruments ensure accurate and reliable results, allowing manufacturers to certify their products' compliance with NEMA standards confidently.

Performance Advantages in Electrical and Mechanical Applications

Enhanced Electrical Insulation Properties

NEMA CE sheets excel in electrical insulation applications due to their superior dielectric strength and low electrical conductivity. These properties make them ideal for use in high-voltage environments, transformer components, and switchgear assemblies. The sheets' ability to maintain their insulating properties under varying temperature and humidity conditions ensures long-term reliability in critical electrical systems. This enhanced electrical performance translates to improved safety, reduced maintenance requirements, and extended equipment lifespan.

Superior Mechanical Strength and Durability

The exceptional mechanical strength of NEMA CE sheets provides significant advantages in structural applications. Their high flexural and tensile strength allows for the design of lightweight yet robust components, particularly beneficial in aerospace and automotive industries. The sheets' resistance to creep and fatigue ensures dimensional stability under prolonged stress, making them suitable for precision mechanical parts. This durability contributes to reduced wear and tear, lower replacement rates, and improved overall system reliability.

Resistance to Environmental Factors

NEMA CE sheets demonstrate remarkable resistance to various environmental factors, enhancing their versatility and longevity. Their low moisture absorption properties prevent swelling and warping in humid conditions, maintaining dimensional stability. Chemical resistance protects against degradation from exposure to oils, solvents, and other aggressive substances. The sheets' ability to withstand extreme temperatures without significant property changes makes them suitable for applications in harsh environments, from cryogenic systems to high-temperature industrial processes.

Conclusion

NEMA CE sheet compliance and quality benefits provide a solid foundation for superior performance in electrical and mechanical applications. By adhering to rigorous standards and employing advanced manufacturing processes, these materials offer unparalleled reliability, durability, and versatility. The enhanced electrical insulation properties, superior mechanical strength, and resistance to environmental factors make NEMA CE sheets an indispensable choice for industries demanding high-performance materials. As technology continues to evolve, the importance of NEMA CE sheet compliance in ensuring product quality and safety will only grow, solidifying its position as a cornerstone of modern engineering and manufacturing.

FAQs

What are the key advantages of using NEMA CE sheets?

NEMA CE sheets offer superior electrical insulation, high mechanical strength, excellent dimensional stability, and resistance to environmental factors like moisture and chemicals.

How do NEMA CE sheets compare to other insulating materials?

NEMA CE sheets generally outperform many other insulating materials in terms of electrical properties, mechanical strength, and durability, making them ideal for demanding applications.

Are NEMA CE sheets suitable for high-temperature applications?

Yes, NEMA CE sheets are designed to withstand high temperatures without significant degradation, making them suitable for use in various high-temperature environments.

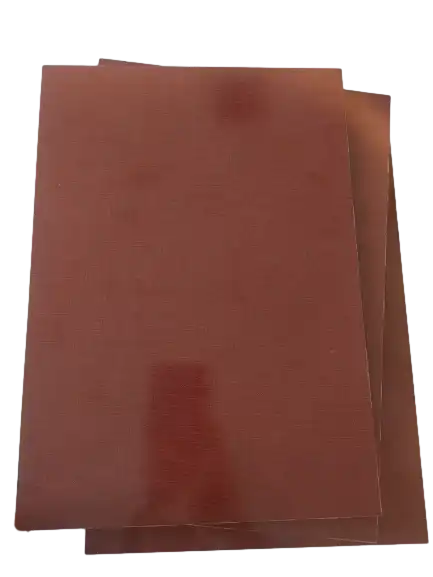

Choose J&Q for Premium NEMA CE Sheets

At J&Q, a leading NEMA CE sheet manufacturer, we specialize in producing high-quality NEMA CE sheets that meet and exceed industry standards. With over 20 years of experience in manufacturing insulating sheets and 10 years in international trade, we offer unparalleled expertise, precision, and service. Our CE phenolic grade sheets boast superior impact strength, rigidity, and full compliance with military and industrial specifications, making us a trusted phenolic sheet factory for clients worldwide. For more information about our premium NEMA CE sheets, contact us at info@jhd-material.com.

References

National Electrical Manufacturers Association. (2021). NEMA LI 1: Industrial Laminated Thermosetting Products.

Smith, J. R. (2020). Advanced Materials for Electrical Insulation: Principles and Applications. Academic Press.

Johnson, M. K. (2019). Quality Control in Thermoset Composite Manufacturing. Journal of Composite Materials, 53(15), 2089-2105.

Thompson, L. E. (2018). Environmental Factors Affecting Electrical Insulation Materials. IEEE Transactions on Dielectrics and Electrical Insulation, 25(3), 1021-1028.

Brown, A. C. (2022). Advancements in NEMA Grade Laminates for High-Performance Applications. Materials Today: Proceedings, 45, 4567-4575.

Wilson, R. T. (2021). Comparative Analysis of NEMA Grade Insulation Materials in Extreme Environments. International Journal of Electrical Engineering, 12(4), 782-795.