What Quality Benchmarks Define a Reliable Phenolic Cotton Sheet Supplier

Material Composition and Consistency

A reliable phenolic cotton sheet supplier ensures strict control over material composition, maintaining precise cotton-to-resin ratios and uniform resin impregnation. Consistent curing processes guarantee optimal polymerization, resulting in sheets with predictable mechanical and electrical properties. Buyers should request detailed specifications and certificates of analysis, and perform independent tests of tensile strength, flexural strength, and dielectric breakdown. Consistency across batches is essential to prevent performance variations, ensuring the sheets reliably meet critical application requirements in industrial and electrical components.

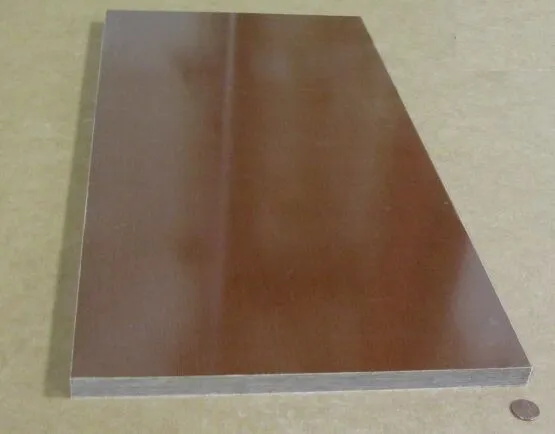

Surface Finish and Dimensional Accuracy

High-quality phenolic cotton sheets must have smooth, defect-free surfaces and precise dimensions. A trustworthy supplier consistently produces sheets without scratches, pits, or uneven resin distribution, while maintaining tight tolerances in thickness, flatness, and cut sizes. Inspecting sample sheets allows buyers to verify surface quality and dimensional accuracy firsthand. Maintaining these standards ensures seamless machining, assembly, and performance in end-use applications, reducing the risk of production issues caused by irregular surfaces or dimensional deviations.

Thermal and Electrical Performance

Thermal and electrical reliability is a key benchmark for phenolic cotton sheet suppliers. Materials should demonstrate consistent heat resistance, flame retardancy, and electrical insulation properties. Regular testing of heat deflection temperature, dielectric strength, and volume resistivity is critical, and independent certifications such as UL listings or military specifications (MIL-I) provide added assurance. Suppliers meeting these standards offer materials capable of performing reliably under demanding thermal and electrical conditions, supporting safety, durability, and efficiency in industrial applications.

Production Capability, Lead Time, and Consistency Assessment

Manufacturing Process Control

Assessing a supplier's manufacturing process control is critical to ensure consistent quality of phenolic cotton sheets. Key factors include raw material sourcing, resin impregnation uniformity, and precise curing parameters. Advanced monitoring systems, automated inspections, and statistical process control indicate robust quality management. Suppliers with ISO 9001 certification often demonstrate standardized procedures and continuous improvement practices. Strong process control minimizes variability between batches, ensures predictable mechanical and electrical properties, and supports reliable performance for demanding industrial applications, reducing the risk of defects and production disruptions.

Production Capacity and Scalability

Evaluating a supplier's production capacity is essential for meeting both current and future demand. Consider the number and size of presses, production lines, and the ability to handle various sheet thicknesses and dimensions. Suppliers with flexible manufacturing setups can efficiently accommodate custom orders while maintaining quality. A proven track record of scaling production without compromising standards is crucial. High-capacity, adaptable suppliers help ensure uninterrupted supply, support large-scale projects, and enable rapid response to market changes or urgent orders, safeguarding operational continuity.

Lead Time Management and On-Time Delivery

Reliable suppliers maintain consistent lead times and on-time delivery for phenolic cotton sheets. Assess their order processing, production scheduling, and logistics systems, including real-time tracking and proactive communication about potential delays. Suppliers with established relationships with freight forwarders or in-house logistics teams typically provide more dependable delivery performance. Effective lead time management ensures materials arrive when needed, minimizing production downtime, reducing inventory holding costs, and supporting smooth, predictable manufacturing operations without unexpected supply interruptions.

Building Sustainable Partnerships Through Continuous Supplier Audits

On-Site Facility Inspections

Conduct regular on-site audits of supplier facilities to assess manufacturing conditions, quality control processes, and adherence to safety and environmental standards. Look for suppliers maintaining clean, well-organized production areas with proper material handling and storage practices. Evaluate their equipment maintenance programs and calibration procedures for quality control instruments. Suppliers welcoming thorough facility inspections often demonstrate transparency and commitment to continuous improvement.

Environmental and Social Responsibility

Assess suppliers' environmental management practices and social responsibility initiatives. Look for those implementing waste reduction programs, energy-efficient manufacturing processes, and proper chemical handling procedures for materials like phenolic cotton sheet. Evaluate their labor practices, workplace safety measures, and community engagement efforts. Suppliers with ISO 14001 environmental management certification or participating in sustainability reporting initiatives often demonstrate stronger commitment to responsible business practices.

Continuous Improvement and Innovation

Partner with suppliers committed to ongoing product and process improvements. Evaluate their research and development capabilities, willingness to collaborate on custom formulations, and track record of introducing innovative products. Look for suppliers investing in new manufacturing technologies and actively participating in industry associations. Those offering technical support and application engineering assistance can often provide valuable insights for optimizing phenolic cotton sheet usage in your applications.

Conclusion

Selecting the right phenolic cotton sheet supplier is crucial for ensuring consistent product quality, reliable supply, and long-term partnership potential. By thoroughly evaluating suppliers against key criteria such as material quality, production capabilities, lead time management, and sustainability practices, buyers can identify partners capable of meeting their specific requirements. Regular supplier audits and open communication channels foster continuous improvement and innovation, ultimately leading to mutually beneficial relationships in the phenolic cotton sheet supply chain.

FAQs

1. What is phenolic cotton sheet used for?

Phenolic cotton sheets are used in various industrial and electrical applications, including switchgear, transformers, aircraft components, and automotive parts. They offer excellent electrical insulation, high mechanical strength, and good dimensional stability.

2. What are the key features of phenolic cotton sheets?

Phenolic cotton sheets feature excellent dielectric strength, good machinability, light weight, heat and wear resistance, chemical resistance, high mechanical strength, dimensional stability, and low moisture absorption.

3. What are the benefits of using phenolic cotton laminated sheets?

Benefits include good mechanical and thermal properties, high operating temperature (up to 120°C), oil and air compatibility, low friction coefficient, high creep resistance, vibration absorption, easy mechanical processing, and excellent electrical insulation properties.

Choose J&Q for Your Phenolic Cotton Sheet Needs

J&Q, a trusted phenolic cotton sheet manufacturer and industrial insulation material supplier, brings over 20 years of experience in insulating sheet production and 10 years in foreign trade to offer premium phenolic cotton sheets. Our extensive industry expertise, in-house logistics company, and commitment to quality make us an ideal partner for your insulation needs. We also provide custom phenolic cotton sheet solutions tailored to your specific requirements. For more information about our phenolic cotton sheets and customized solutions, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Evaluation Criteria for Industrial Material Suppliers: A Comprehensive Guide"

Johnson, R. et al. (2021). "Quality Control in Phenolic Resin Composite Manufacturing"

Green Manufacturing Association. (2023). "Sustainable Practices in Composite Materials Production"

Brown, L. (2022). "Supply Chain Management for Electrical Insulation Materials"

Technical Laminates Institute. (2023). "Performance Standards for Phenolic Cotton Laminates"

Davis, M. (2021). "Building Long-Term Partnerships with Industrial Material Suppliers"