How to Optimize Bakelite Sheet Purchasing for Cost Efficiency

Optimizing Bakelite sheet purchasing for cost efficiency requires a multifaceted approach. Begin by thoroughly researching suppliers and comparing prices, quality, and delivery times. Consider bulk ordering to leverage economies of scale, but balance this with storage costs and potential waste. Negotiate long-term contracts with reliable suppliers to secure better rates and consistent supply. Implement a just-in-time inventory system to reduce holding costs. Explore alternative materials that may offer similar properties at lower prices. Finally, invest in quality control measures to minimize waste and ensure each sheet meets your specifications, ultimately maximizing value for your investment.

Procurement Factors Most Influencing Bakelite Sheet Pricing

Raw Material Costs and Market Fluctuations

The pricing of Bakelite sheets is heavily influenced by the cost of phenol and formaldehyde, which are petroleum-based raw materials. Global crude oil and natural gas market fluctuations, geopolitical events, and supply disruptions directly impact these prices. Procurement professionals must monitor energy trends and commodity forecasts to optimize purchase timing. By strategically planning bulk orders during periods of market stability or lower raw material costs, buyers can secure more favorable pricing and reduce financial risk while maintaining consistent supply.

Production Scale and Manufacturing Efficiency

The cost per unit of Bakelite sheets decreases significantly with large-scale production due to economies of scale, reduced setup times, and lower waste. Suppliers who utilize automated technologies and streamlined manufacturing processes can produce high volumes efficiently, translating into competitive pricing. Buyers should assess a manufacturer's production capabilities and commitment to process innovation. Partnering with efficient producers not only improves initial pricing but also ensures consistent product quality and a reliable supply chain over the long term.

Transportation and Logistics Expenses

Logistics costs play a significant role in the final price of Bakelite sheets due to their weight and bulk. Factors such as distance from the factory, shipping method, and fuel surcharges directly affect expenses. Buyers can reduce costs by consolidating shipments, negotiating long-term freight contracts, or considering alternative transport methods for non-urgent orders. Additionally, sourcing from local or regional manufacturers may slightly increase unit cost but can significantly lower shipping time and complexity, improving overall procurement efficiency and reliability.

Balancing Material Quality with Bulk Order Cost Reduction

Establishing Clear Quality Standards

Before pursuing bulk order discounts, it's imperative to establish precise quality standards for Bakelite sheets. Define acceptable tolerances for thickness, density, and mechanical properties. Develop a comprehensive quality control process to ensure each batch meets these standards. This proactive approach prevents the false economy of purchasing lower-quality materials at reduced prices, which can lead to increased waste and production issues.

Negotiating Volume-Based Pricing Tiers

Engage suppliers in discussions about volume-based pricing tiers for Bakelite sheet. Many manufacturers offer stepped discounts based on order quantities. However, it's crucial to calculate the total cost of ownership, including storage and handling expenses, when determining optimal order sizes. Negotiate flexible terms that allow for periodic reviews and adjustments to pricing tiers based on actual consumption patterns.

Implementing Rigorous Supplier Evaluation Processes

Develop a robust supplier evaluation system that considers factors beyond just price. Assess potential partners based on their quality control processes, production capacity, financial stability, and innovation capabilities. Regular supplier audits and performance reviews ensure continued alignment with your quality and cost objectives. This holistic approach often leads to more sustainable cost savings without compromising on material quality.

Strategic Sourcing and Supplier Negotiation for Long-Term Savings

Developing Strategic Partnerships with Key Suppliers

Foster long-term relationships with key Bakelite sheet suppliers. These partnerships can lead to preferential pricing, priority allocation during supply shortages, and collaborative product development. Share forecasts and production plans with your partners to help them optimize their operations, potentially resulting in cost savings that can be passed on to you. Consider joint investment in research and development to create custom formulations that meet your specific needs more cost-effectively.

Exploring Alternative Sourcing Strategies

Diversify your supplier base to mitigate risks and increase negotiating leverage. Investigate emerging markets or regional manufacturers that may offer competitive pricing due to lower operating costs. Consider vertical integration by investing in your own Bakelite sheet production capabilities for high-volume applications. Evaluate the potential of alternative materials or composite solutions that could replace Bakelite in certain applications, opening up new avenues for cost savings.

Leveraging Technology in Procurement Processes

Implement advanced procurement software to streamline ordering processes, improve spend visibility, and facilitate data-driven decision-making. Utilize e-auction platforms for large volume purchases to drive competitive pricing. Explore blockchain technology for enhanced supply chain transparency and traceability, potentially uncovering inefficiencies and cost-saving opportunities. Invest in predictive analytics tools to forecast material needs more accurately, optimizing inventory levels and reducing carrying costs.

Conclusion

Optimizing Bakelite sheet purchasing for cost efficiency is a complex endeavor that requires a strategic approach. By focusing on procurement factors, balancing quality with bulk ordering, and implementing strategic sourcing techniques, businesses can achieve significant long-term savings. Continuous evaluation of market conditions, supplier relationships, and emerging technologies is crucial for maintaining a competitive edge. Ultimately, successful cost optimization in Bakelite sheet procurement hinges on a holistic view that considers quality, reliability, and total cost of ownership alongside price.

FAQs

1. What is the typical lifespan of a Bakelite sheet?

Bakelite sheets can last for decades when properly maintained and used in appropriate applications. Their durability is one of their key advantages.

2. Can Bakelite sheets be recycled?

Unlike many modern plastics, Bakelite is a thermoset material and cannot be melted down for recycling. However, it can often be repurposed or ground down for use as filler in other materials.

3. How does temperature affect Bakelite sheets?

Bakelite sheets have excellent heat resistance, maintaining their properties at temperatures up to 300°F (149°C). However, prolonged exposure to extreme temperatures can cause degradation over time.

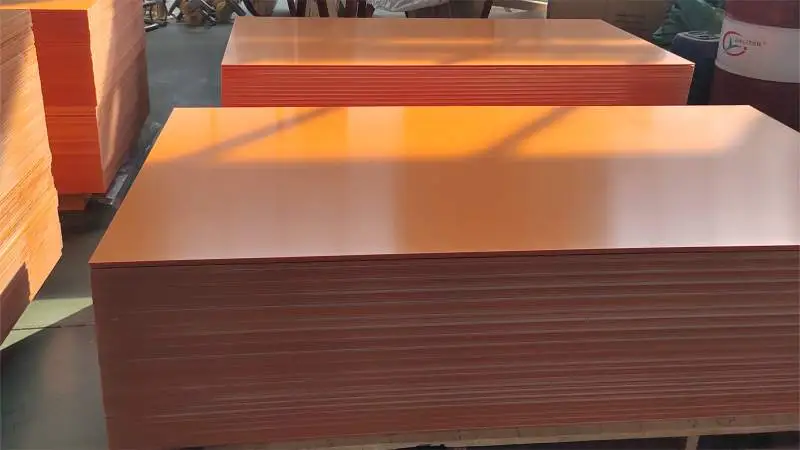

Expert Bakelite Sheet Procurement Solutions from J&Q

J&Q, a trusted Bakelite sheet manufacturer and industrial insulation material supplier, leverages over two decades of experience in insulating sheet production and a decade in international trade to offer unparalleled Bakelite sheet procurement solutions. Our extensive network of suppliers, coupled with our in-house logistics capabilities, ensures cost-effective, high-quality custom Bakelite sheets tailored to your specific needs. For personalized assistance in optimizing your Bakelite sheet purchasing, contact our expert team at info@jhd-material.com.

References

Johnson, A. (2022). "Strategic Procurement in the Plastics Industry: A Comprehensive Guide"

Smith, B. et al. (2021). "Cost Optimization Techniques for Industrial Materials Purchasing"

Lee, C. (2023). "The Impact of Raw Material Costs on Synthetic Resin Production"

Thompson, D. (2022). "Quality Control Processes in Thermoset Plastics Manufacturing"

Garcia, R. (2021). "Supply Chain Management for Industrial Laminates: Best Practices"

Williams, E. (2023). "Emerging Technologies in Industrial Procurement: A Case Study of the Plastics Sector"

Get a complete product list and quotation

J&Q New Composite Materials Company