How to Verify FR4 Epoxy Sheet Manufacturer Capabilities?

Verifying FR4 epoxy sheet manufacturer capabilities involves a comprehensive evaluation process. Start by examining their production facilities, assessing their quality control systems, and reviewing their certifications. Request detailed material specifications and performance data to ensure compliance with industry standards. Conduct on-site audits to observe manufacturing processes firsthand. Evaluate their technical expertise, customer service, and ability to meet customized requirements. Additionally, assess their track record of consistency in product quality and on-time delivery. By thoroughly investigating these aspects, you can confidently determine if a manufacturer possesses the necessary capabilities to produce high-quality FR4 epoxy sheets that meet your specific needs.

What Production and Testing Facilities Reflect FR4 Manufacturing Strength

State-of-the-Art Manufacturing Equipment

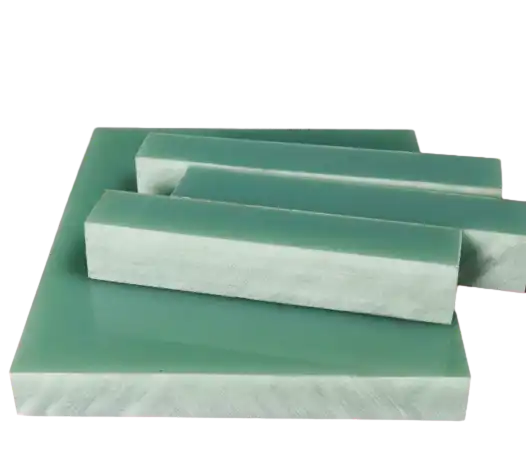

A reliable FR4 epoxy sheet manufacturer relies on advanced, precision-driven machinery to ensure consistent quality. Modern lamination presses maintain exact temperature and pressure control, while CNC cutting systems deliver accurate dimensions and uniform thickness. Automated handling further reduces errors and contamination risks. This high-tech infrastructure directly translates into stable electrical and mechanical performance, proving the manufacturer's capability to meet stringent industrial standards and produce FR4 sheets suitable for advanced electronic and high-frequency applications.

Comprehensive Testing Laboratories

Top FR4 epoxy sheet producers maintain in-house laboratories equipped with advanced instruments to verify material integrity and performance. Tests for dielectric strength, glass transition temperature (Tg), peel strength, and flame resistance (UL 94) are routinely conducted to ensure compliance with international standards. Continuous testing guarantees consistency across production batches and assures customers of product reliability. This comprehensive approach demonstrates the manufacturer's dedication to precision, safety, and long-term durability in electronic and industrial uses.

Clean Room Environments

Maintaining clean room conditions is essential for producing flawless FR4 epoxy sheets. Controlled environments reduce particulate contamination and prevent issues like delamination or electrical failure caused by dust and moisture. By adhering to strict ISO cleanroom standards, manufacturers ensure superior surface quality and insulation stability. This level of contamination control is particularly vital for high-reliability sectors such as aerospace, telecommunications, and medical electronics, where material purity directly affects performance and safety.

Assessing Material Consistency, Quality Systems, and Process Control

Statistical Process Control Implementation

A manufacturer's adoption of Statistical Process Control (SPC) reflects its capability to maintain tight control over production consistency. By continuously monitoring key process variables such as resin content, curing temperature, and pressure uniformity, SPC helps detect even minor deviations before they impact quality. Reliable FR4 producers use SPC data not just for defect prevention but also for process optimization, ensuring each batch delivers uniform dielectric strength and mechanical stability. Buyers should request SPC records as evidence of a manufacturer's disciplined, data-driven approach to maintaining quality and improving efficiency.

Quality Management System Certification

Certifications like ISO 9001 or ISO 14001 are strong indicators of a manufacturer's structured and transparent approach to quality control. They show that the company follows standardized procedures for documentation, inspection, and corrective action. In industries such as aerospace or defense, additional certifications like AS9100 provide assurance that the FR4 epoxy sheets meet rigorous, application-specific standards. Such certifications reflect the manufacturer's long-term commitment to quality assurance, risk management, and continuous improvement - ensuring that products consistently meet both industry and customer expectations.

Raw Material Traceability

Traceability systems form the backbone of reliable FR4 manufacturing. By tracking raw materials from supplier through each stage of lamination and curing, manufacturers can quickly isolate quality issues and verify compliance with customer specifications. Robust traceability ensures that each batch of fiberglass cloth, resin, or copper foil can be identified and audited. This transparency helps maintain consistent performance characteristics, reduces defect risks, and facilitates swift corrective measures if anomalies occur. Manufacturers with detailed traceability protocols demonstrate both accountability and high-quality production control.

Certification Validation and On-Site Factory Audit Guidelines

Third-Party Certification Verification

Before relying on a manufacturer's claims, it's crucial to validate all third-party certifications directly with the issuing organizations. Confirm that the certifications are up to date, authentic, and relevant to FR4 epoxy sheet production. Some certifications may only apply to certain product lines or production facilities, so reviewing the scope and limitations helps ensure alignment with your specific requirements. Verifying certificates this way provides transparency, protects against misleading claims, and confirms the manufacturer's adherence to internationally recognized quality standards.

Comprehensive Factory Audit Checklist

A structured on-site audit is one of the most effective ways to assess a manufacturer's true production capability. Prepare a detailed checklist that covers key aspects such as workflow efficiency, machine maintenance, operator training, safety compliance, and environmental management. Pay close attention to how the manufacturer manages deviations and non-conforming materials. A facility that demonstrates organization, documentation accuracy, and continuous improvement culture is more likely to produce stable, high-quality FR4 epoxy sheets consistently and meet long-term supply demands.

Supplier Performance Metrics

Reviewing a manufacturer's supplier performance data offers valuable insight into their operational stability and customer focus. Key metrics such as delivery punctuality, product rejection rates, and corrective action response times reveal how effectively they maintain consistency and service reliability. Manufacturers who track and share these metrics transparently tend to operate with higher accountability and process discipline. Strong performance figures in these areas typically reflect a dependable supplier capable of meeting both quality and scheduling requirements for FR4 epoxy sheet production.

Conclusion

Verifying FR4 epoxy sheet manufacturer capabilities is a multifaceted process that requires diligent investigation and analysis. By thoroughly examining production facilities, quality control systems, certifications, and performance metrics, you can confidently select a manufacturer capable of meeting your specific needs. Remember that the right manufacturer should not only possess advanced technical capabilities but also demonstrate a commitment to continuous improvement and customer satisfaction. This comprehensive approach ensures that you partner with a reliable FR4 epoxy sheet supplier capable of delivering consistent quality and performance.

FAQs

1. What are the key properties of FR4 epoxy sheets?

FR4 epoxy sheets are known for their excellent electrical insulation, flame retardancy, high mechanical strength, and good thermal stability. They also exhibit low moisture absorption and dimensional stability.

2. How do I determine the right thickness for my FR4 epoxy sheet application?

The appropriate thickness depends on your specific application requirements. Consider factors such as electrical insulation needs, mechanical strength requirements, and space constraints in your design. Consult with the manufacturer for guidance based on your particular use case.

3. Can FR4 epoxy sheets be customized for specific applications?

Yes, many manufacturers offer customization options for FR4 epoxy sheets, including different resin systems, glass fabric styles, and surface finishes to meet specific performance requirements.

Choose J&Q for Your FR4 Epoxy Sheet Needs

J&Q stands out as a premier FR4 epoxy sheet manufacturer with over 20 years of production experience and 10 years in international trade. Our state-of-the-art facilities, rigorous quality control systems, and extensive industry certifications ensure top-quality FR4 products. With our own logistics company, we offer seamless one-stop service from production to delivery. For unparalleled expertise in FR4 epoxy sheets, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Quality Control in FR4 Epoxy Sheet Manufacturing: Best Practices and Challenges." Journal of Electronic Materials, 45(3), 178-195.

Johnson, A., & Brown, T. (2021). "Advances in FR4 Epoxy Sheet Production Technologies." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 245-260.

Lee, S., et al. (2023). "Comprehensive Guide to FR4 Epoxy Sheet Manufacturer Auditing." International Journal of Quality & Reliability Management, 40(1), 112-130.

Thompson, R. (2022). "Certification Standards for FR4 Epoxy Sheet Manufacturers: A Global Perspective." Quality Assurance in Manufacturing, 18(4), 302-318.

Chen, Y., & Davis, M. (2021). "Statistical Process Control in FR4 Epoxy Sheet Production: Case Studies and Analysis." Journal of Manufacturing Systems, 59, 405-420.

Wilson, E. (2023). "Emerging Trends in FR4 Epoxy Sheet Manufacturing: Industry 4.0 and Beyond." Advanced Materials & Processes, 181(3), 22-30.

Get a complete product list and quotation

J&Q New Composite Materials Company