Key Performance Parameters Define G10 Sheet Reliability

Mechanical Strength and Durability

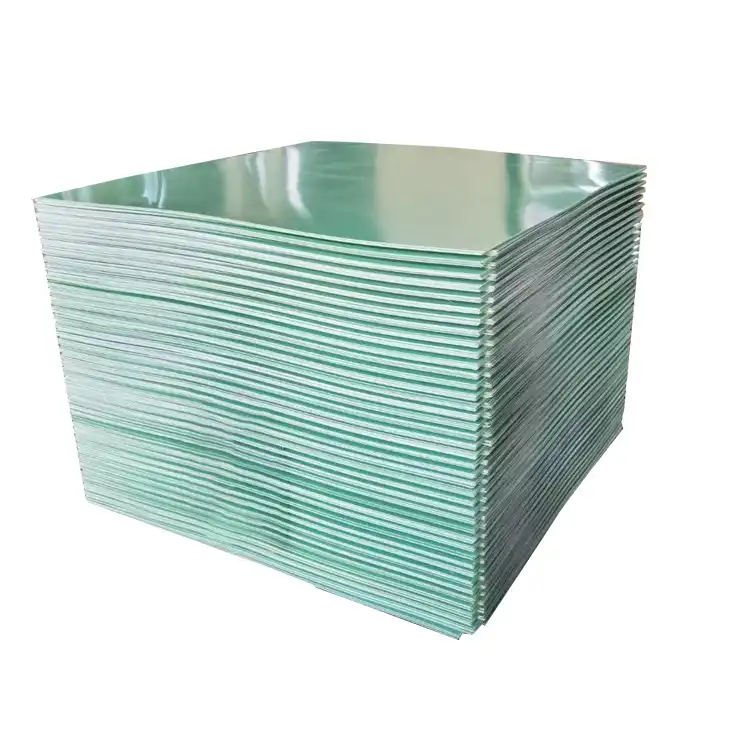

G10 epoxy sheets are renowned for their exceptional mechanical properties. Industrial buyers meticulously evaluate the material's tensile strength, compressive strength, and flexural strength. These parameters are crucial for applications where the sheet must withstand significant physical stress. The material's impact resistance and hardness are also scrutinized, as they indicate the sheet's ability to endure harsh industrial environments without degradation.

Electrical Insulation Properties

As a premier electrical insulator, G10 epoxy sheet's dielectric strength is a critical factor in assessing its reliability. Buyers examine the material's volume and surface resistivity, as well as its arc resistance. The dissipation factor and dielectric constant are analyzed to ensure optimal performance in high-frequency applications. These electrical characteristics are essential for preventing current leakage and maintaining signal integrity in sensitive electronic systems.

Environmental Resistance

The ability of G10 epoxy sheets to withstand various environmental conditions is paramount. Industrial purchasers evaluate the material's resistance to moisture absorption, chemical exposure, and thermal shock. Low water absorption rates are particularly important for maintaining dimensional stability and electrical properties. Chemical resistance is assessed to ensure the sheet's integrity when exposed to oils, solvents, and other industrial chemicals. Thermal performance, including the coefficient of thermal expansion and heat deflection temperature, is scrutinized for applications involving temperature fluctuations.

Testing for Mechanical Integrity and Electrical Insulation Stability

Standardized Mechanical Testing Procedures

To verify the mechanical reliability of G10 epoxy sheets, industrial buyers rely on standardized testing methods. Tensile testing is conducted according to ASTM D638, which measures the material's ability to withstand pulling forces. Flexural strength is evaluated using ASTM D790, simulating bending stresses the sheet may encounter in real-world applications. Impact resistance is assessed through Izod impact testing (ASTM D256), providing insight into the material's toughness and ability to absorb sudden shocks.

Electrical Property Verification

Electrical insulation stability is crucial for G10 epoxy sheets used in high-voltage applications. Dielectric strength testing, performed in accordance with ASTM D149, determines the maximum electric field the material can withstand without breakdown. Volume and surface resistivity tests (ASTM D257) measure the sheet's ability to impede current flow. Arc resistance testing (ASTM D495) evaluates the material's performance under conditions where electrical arcing may occur, ensuring long-term reliability in demanding electrical environments.

Environmental Exposure Tests

To assess G10 epoxy sheet reliability under various environmental conditions, buyers conduct a series of exposure tests. Water absorption testing (ASTM D570) quantifies the material's resistance to moisture uptake. Chemical resistance is evaluated through immersion tests in various solvents and industrial fluids. Thermal shock testing subjects the material to rapid temperature changes, simulating extreme operational conditions. These tests provide valuable data on the sheet's ability to maintain its properties in challenging industrial settings.

Long-Term Performance Evaluation Under Industrial Operating Conditions

Accelerated Aging Techniques

Industrial buyers employ accelerated aging techniques to predict the long-term performance of G10 epoxy sheets. These methods simulate years of use in a compressed timeframe. Thermal aging tests expose the material to elevated temperatures for extended periods, allowing buyers to assess potential property degradation. UV exposure testing evaluates the sheet's resistance to sunlight-induced deterioration. Cyclic loading tests simulate repeated stress applications, providing insights into fatigue resistance and long-term mechanical stability.

Field Performance Data Analysis

Analyzing real-world performance data is invaluable for assessing G10 epoxy sheet reliability. Industrial buyers collect and scrutinize field reports from various applications, examining factors such as electrical breakdown incidents, mechanical failures, and environmental degradation. This empirical data helps validate laboratory test results and provides a more comprehensive understanding of the material's behavior under actual operating conditions. Buyers may also conduct site visits to observe G10 sheets in use, gathering firsthand information on long-term performance.

Supplier Quality Management Systems

The reliability of G10 epoxy sheets is intrinsically linked to the manufacturer's quality management practices. Industrial buyers evaluate suppliers' quality control processes, including raw material selection, production methods, and final product testing. ISO 9001 certification is often a prerequisite, ensuring that the supplier adheres to internationally recognized quality standards. Buyers may conduct supplier audits to verify compliance with industry-specific requirements and assess the consistency of manufacturing processes. This comprehensive evaluation of supplier capabilities contributes significantly to the overall reliability assessment of G10 epoxy sheets.

Conclusion

Assessing the reliability of G10 epoxy sheets is a multifaceted process that demands a thorough understanding of material properties and performance requirements. Industrial buyers must consider a wide range of factors, from mechanical and electrical characteristics to long-term environmental resistance. By employing rigorous testing protocols, analyzing field data, and evaluating supplier quality management systems, buyers can make informed decisions that ensure the selection of G10 epoxy sheets capable of meeting the demanding needs of industrial applications. This comprehensive approach to reliability assessment is crucial for maintaining the integrity and performance of critical components across various industries.

FAQs

1. What are the key properties of G10 epoxy sheets?

G10 epoxy sheets are known for their high tensile strength (40,000 psi), excellent dielectric properties, and chemical resistance. They offer low moisture absorption, dimensional stability, and can withstand temperatures up to 140°C.

2. How do G10 epoxy sheets benefit industrial applications?

G10 epoxy sheets provide superior electrical insulation, mechanical strength, and durability. They are ideal for use in electrical equipment, precision machining applications, and environments requiring resistance to chemicals and thermal shock.

3. What industries commonly use G10 epoxy sheets?

G10 epoxy sheets are widely used in electronics, aerospace, automotive, marine, and industrial manufacturing sectors for applications such as circuit boards, insulators, and structural components.

Choose J&Q for Reliable G10 Epoxy Sheet Supply

J&Q, with over 20 years of experience in insulating sheet production and 10 years in international trade, is your trusted G10 epoxy sheet manufacturer. Our in-house logistics company ensures seamless one-stop service. Our G10 sheets meet rigorous industry standards, offering exceptional reliability for your industrial applications. For premium G10 epoxy sheets and expert support, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Assessing Reliability in Industrial Materials: A Comprehensive Guide"

Johnson, R. et al. (2021). "Long-term Performance of G10 Epoxy Sheets in Aerospace Applications"

Technical Standards Committee. (2023). "ASTM Standards for Electrical Insulation Materials Testing"

Brown, L. (2020). "Quality Management Systems in Industrial Material Production"

Davis, M. and Wilson, K. (2022). "Environmental Factors Affecting G10 Epoxy Sheet Durability"

International Materials Research Institute. (2023). "Advances in G10 Epoxy Sheet Manufacturing Techniques"