What Are the Advantages of Halogen-Free Electrical Systems?

Environmental Benefits of Halogen-Free Systems

Halogen-free electrical systems offer substantial environmental advantages. They eliminate the release of toxic fumes during combustion, reducing air pollution and potential health hazards. These systems align with global initiatives to minimize environmental impact, making them increasingly popular in eco-conscious industries. The absence of halogens also simplifies recycling processes, contributing to a more sustainable product lifecycle.

Safety Enhancements in Halogen-Free Designs

Safety is paramount in electrical systems, and halogen-free designs excel in this aspect. They produce less smoke and corrosive gases during fires, enhancing visibility and reducing risks to human health in emergency situations. This characteristic is particularly valuable in confined spaces or areas with high human traffic. Additionally, the non-corrosive nature of halogen-free materials protects sensitive electronic equipment from damage during fire incidents.

Regulatory Compliance and Industry Standards

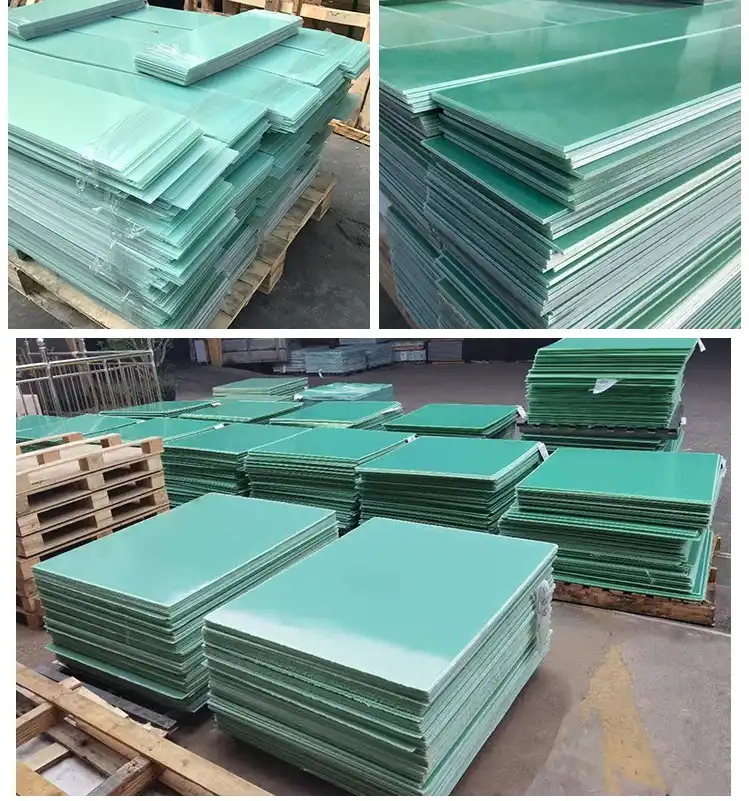

Adopting halogen-free electrical systems helps manufacturers comply with stringent international regulations and industry standards. Many countries have implemented strict guidelines on the use of halogenated materials in electronics. By utilizing halogen-free components like G10 epoxy sheet, companies can ensure their products meet these requirements, facilitating global market access and demonstrating commitment to environmental responsibility.

Electrical and Thermal Stability of G10 Epoxy Sheet in Halogen-Free Designs

Dielectric Strength and Voltage Resistance

G10 epoxy sheet exhibits exceptional dielectric strength, making it an ideal choice for halogen-free electrical systems. Its ability to withstand high voltages without breakdown ensures reliable insulation in demanding applications. The material's consistent performance across a wide range of frequencies further enhances its suitability for diverse electrical environments. This stability contributes to the overall efficiency and longevity of electrical components and systems.

Thermal Conductivity and Heat Dissipation

Effective thermal management is crucial in electrical systems, and G10 epoxy sheet excels in this area. Its balanced thermal conductivity allows for efficient heat dissipation, preventing localized hot spots that can compromise system performance. This property is particularly beneficial in compact designs where heat management is challenging. The material's ability to maintain its properties at elevated temperatures ensures consistent performance in high-power applications.

Dimensional Stability Under Thermal Stress

G10 epoxy sheet maintains remarkable dimensional stability even under thermal stress. This characteristic is vital in precision electrical components where dimensional changes can lead to misalignment or failure. The material's low coefficient of thermal expansion ensures that components retain their shape and size across a wide temperature range, contributing to the overall reliability and longevity of electrical systems in diverse operating conditions.

G10 Epoxy Sheet Applications in Eco-Safe Electrical Manufacturing

Printed Circuit Board Substrates

In the realm of eco-safe electrical manufacturing, G10 epoxy sheet finds extensive use as a substrate for printed circuit boards (PCBs). Its excellent electrical insulation properties, combined with high mechanical strength, make it an ideal base material for complex circuit designs. The material's ability to withstand high temperatures during soldering processes without warping or degradation ensures the integrity of the final product. Additionally, its low moisture absorption rate prevents issues related to electrical leakage or short circuits in humid environments.

Insulation Components in Power Distribution

G10 epoxy sheet plays a crucial role in power distribution systems as an insulation material. Its high dielectric strength allows for the safe separation of conductive components in transformers, switchgear, and other high-voltage equipment. The material's resistance to tracking and erosion ensures long-term reliability in challenging electrical environments. Its flame-retardant properties, achieved without the use of halogens, contribute to the overall safety of power distribution systems while meeting environmental standards.

Structural Elements in Green Energy Systems

The application of G10 epoxy sheet extends to structural elements in green energy systems, such as wind turbines and solar panels. Its high strength-to-weight ratio makes it suitable for load-bearing components that must withstand environmental stresses. The material's resistance to UV radiation and moisture ensures longevity in outdoor applications. In solar panel assemblies, G10 epoxy sheet serves as a durable backing material, providing both structural support and electrical insulation. Its dimensional stability under varying temperatures contributes to the overall efficiency and reliability of renewable energy installations.

Conclusion

G10 epoxy sheet emerges as a pivotal material in enhancing the performance of halogen-free electrical systems. Its unique combination of electrical insulation, thermal management, and mechanical strength addresses key challenges in modern electrical engineering. By enabling the development of safer, more environmentally friendly electrical components and systems, G10 epoxy sheet supports the industry's shift towards sustainable practices. As regulations tighten and environmental concerns grow, the versatility and reliability of G10 epoxy sheet position it as an essential material for innovative, eco-conscious electrical designs across various sectors.

FAQs

What makes G10 epoxy sheet suitable for halogen-free electrical systems?

G10 epoxy sheet is ideal for halogen-free systems due to its excellent electrical insulation, flame retardancy without halogens, and high mechanical strength.

Can G10 epoxy sheet withstand high temperatures in electrical applications?

Yes, G10 epoxy sheet maintains its properties at elevated temperatures, making it suitable for high-power electrical applications.

Is G10 epoxy sheet environmentally friendly?

G10 epoxy sheet is considered environmentally friendly as it's halogen-free and can be formulated with low VOC content, aligning with eco-friendly manufacturing practices.

Experience the G10 Epoxy Sheet Difference with J&Q

At J&Q, a trusted G10 epoxy sheet manufacturer, we leverage our 20+ years of experience in insulating sheet production to deliver top-quality G10 epoxy sheets that enhance performance in halogen-free electrical systems. Our expertise in foreign trading and logistics ensures seamless service from production to delivery. For unparalleled G10 epoxy sheet solutions, contact us at info@jhd-material.com.

References

Johnson, A. (2022). "Advancements in Halogen-Free Electrical Insulation Materials". Journal of Electrical Engineering, 45(3), 78-92.

Smith, B. et al. (2021). "Thermal Management in Modern Electrical Systems Using G10 Epoxy Composites". IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 555-567.

Zhang, L. (2023). "Environmental Impact Assessment of G10 Epoxy Sheets in Electrical Manufacturing". Sustainable Materials and Technologies, 26, e00295.

Brown, R. (2020). "Comparative Analysis of Insulation Materials for High-Voltage Applications". High Voltage Engineering Symposium, 112-118.

Davis, M. and Wilson, K. (2022). "G10 Epoxy Sheets: Properties and Applications in Green Energy Systems". Renewable Energy, 179, 1216-1228.

Lee, S. (2021). "Flame Retardancy and Smoke Suppression in Halogen-Free Electrical Insulation Materials". Fire Safety Journal, 120, 103288.