What Role Does G10 Epoxy Fiberglass Sheet Play in Eco-Conscious Engineering?

Sustainable Material Composition

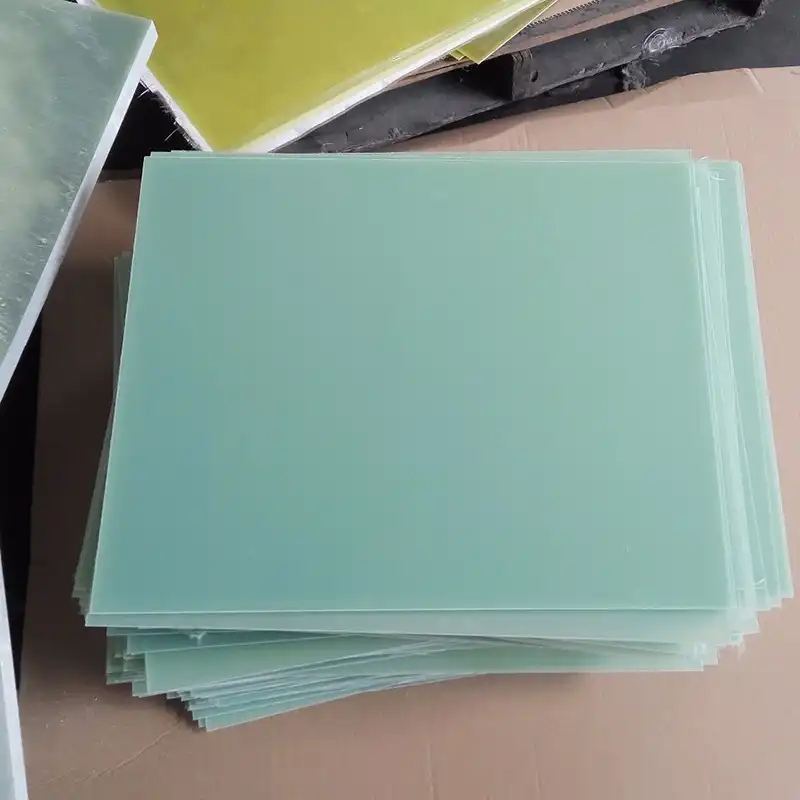

G10 epoxy fiberglass sheet, a composite material, exemplifies sustainable engineering practices through its composition. The fiberglass reinforcement provides exceptional strength and durability, while the epoxy resin binder offers superior chemical resistance and electrical insulation properties. This unique combination results in a material that not only performs exceptionally well but also contributes to reduced environmental impact in several ways.

The longevity of G10 epoxy fiberglass sheet significantly reduces the need for frequent replacements, thereby minimizing waste generation and resource consumption. Its resistance to corrosion, moisture, and chemical degradation ensures that components made from this material maintain their integrity over extended periods, even in harsh environments. This durability translates to fewer replacements and less material waste over time, aligning with the principles of sustainable design and circular economy.

Furthermore, the manufacturing process of G10 epoxy fiberglass sheet has seen advancements in recent years, with some manufacturers adopting more environmentally friendly production methods. These include using low-VOC (Volatile Organic Compound) resins and optimizing the curing process to reduce energy consumption. Such improvements in production techniques contribute to lowering the overall carbon footprint associated with G10 epoxy fiberglass sheet, making it an increasingly attractive option for eco-conscious engineers and designers.

Energy Efficiency in Electrical Systems

G10 epoxy fiberglass sheet significantly enhances energy efficiency in electrical systems through its exceptional insulating properties. The material's low dielectric constant and high dielectric strength make it an ideal choice for applications where minimizing energy losses is crucial. In power distribution systems, for instance, G10 components can help reduce leakage currents and improve overall system efficiency.

The thermal stability of G10 epoxy fiberglass sheet also contributes to energy efficiency. Its ability to maintain its properties across a wide temperature range means that electrical systems can operate more consistently and efficiently, even under varying environmental conditions. This stability reduces the need for additional cooling or heating systems in certain applications, further conserving energy.

Moreover, the lightweight nature of G10 epoxy fiberglass sheet allows for the design of more compact and efficient electrical components. This reduction in size and weight can lead to decreased energy requirements in transportation and installation, as well as improved energy efficiency in mobile or portable electrical devices. By enabling the creation of more streamlined and efficient electrical systems, G10 epoxy fiberglass sheet plays a vital role in reducing overall energy consumption and supporting sustainable design practices.

Recyclability and End-of-Life Considerations

While G10 epoxy fiberglass sheet offers numerous benefits in terms of sustainability during its use phase, its end-of-life management presents both challenges and opportunities. The composite nature of the material makes traditional recycling methods difficult. However, innovative approaches are being developed to address this issue and improve the material's overall lifecycle sustainability.

Advanced recycling technologies, such as pyrolysis and chemical recycling, are being explored to recover valuable components from G10 epoxy fiberglass sheet at the end of its useful life. These processes aim to separate the glass fibers from the epoxy resin, allowing for the potential reuse of these materials in new applications. While these technologies are still in development, they show promise for improving the circularity of G10 and similar composite materials.

Additionally, some manufacturers are investigating the use of bio-based epoxy resins in the production of G10-like materials. These alternative resins, derived from renewable resources, could potentially improve the biodegradability of the composite without compromising its performance characteristics. Such innovations demonstrate the ongoing efforts to enhance the sustainability profile of G10 epoxy fiberglass sheet throughout its entire lifecycle, from production to disposal or recycling.

Electrical Insulation and Energy Efficiency of G10 Epoxy Fiberglass Sheet

Superior Dielectric Properties

G10 epoxy fiberglass sheet boasts exceptional dielectric properties, making it an indispensable material in high-performance electrical insulation applications. Its low dielectric constant ensures minimal energy storage within the material, reducing capacitive effects that can lead to power losses in electrical systems. This characteristic is particularly valuable in high-frequency applications where signal integrity is paramount.

The high dielectric strength of G10 epoxy fiberglass sheet allows it to withstand substantial electric fields without breakdown. This property enables the design of compact yet highly effective insulation systems, crucial for the miniaturization of electrical components without compromising safety or performance. In power transmission and distribution applications, G10 components can help prevent electrical arcing and improve overall system reliability.

Furthermore, the dielectric properties of G10 epoxy fiberglass sheet remain stable across a wide range of temperatures and frequencies. This stability ensures consistent insulation performance under varying operating conditions, contributing to the overall efficiency and reliability of electrical systems. The material's ability to maintain its insulating properties in challenging environments makes it an ideal choice for applications in aerospace, automotive, and industrial sectors where extreme conditions are common.

Thermal Management in Electrical Systems

While G10 epoxy fiberglass sheet is primarily known for its electrical insulation properties, its thermal characteristics also play a crucial role in energy-efficient electrical design. The material's low thermal conductivity helps prevent heat transfer between components, which can be beneficial in managing thermal loads within electrical systems. This property is particularly valuable in applications where thermal isolation is necessary to maintain the integrity and efficiency of sensitive components.

The dimensional stability of G10 epoxy fiberglass sheet under varying temperatures contributes to the reliable operation of electrical systems. Unlike some materials that may expand or contract significantly with temperature changes, G10 maintains its shape and properties, ensuring consistent performance and preventing stress on connected components. This stability can lead to reduced maintenance requirements and extended system lifespans, further enhancing the overall sustainability of electrical designs.

In applications where heat dissipation is crucial, G10 epoxy fiberglass sheet can be engineered with specific thermal management features. For instance, thermally conductive fillers can be incorporated into the material to enhance heat transfer in specific directions while maintaining electrical isolation. This tailored approach to thermal management allows designers to optimize the balance between electrical insulation and heat dissipation, resulting in more energy-efficient and reliable electrical systems.

Impact on Power Transmission Efficiency

The use of G10 epoxy fiberglass sheet in power transmission components significantly enhances overall system efficiency. Its excellent insulating properties minimize power losses due to leakage currents, which can be substantial in high-voltage applications. By reducing these losses, G10 components contribute to more efficient power transmission over long distances, a critical factor in sustainable energy distribution.

In switchgear and transformer applications, G10 epoxy fiberglass sheet provides robust insulation while allowing for compact designs. This combination of high performance and space efficiency enables the creation of more powerful yet smaller substations and distribution equipment. The reduced size not only saves on material usage but also allows for more efficient land use in urban areas, aligning with sustainable urban planning principles.

Moreover, the durability and resistance to environmental factors exhibited by G10 epoxy fiberglass sheet translate to reduced maintenance requirements for power transmission infrastructure. This longevity not only reduces the lifecycle costs of electrical systems but also minimizes the environmental impact associated with frequent repairs and replacements. By contributing to the development of more reliable and efficient power transmission systems, G10 epoxy fiberglass sheet plays a vital role in supporting the transition to sustainable energy grids and smart city infrastructures.

G10 Epoxy Fiberglass Sheet for Sustainable and Long-Life Electrical Systems

Durability and Longevity in Harsh Environments

G10 epoxy fiberglass sheet exhibits remarkable durability and longevity, particularly in harsh environmental conditions. Its resistance to moisture, chemicals, and temperature extremes ensures that electrical components made from this material maintain their integrity and performance over extended periods. This resilience is crucial for sustainable electrical systems, as it significantly reduces the need for frequent replacements and maintenance.

In marine and offshore applications, where corrosion and moisture are constant challenges, G10 epoxy fiberglass sheet proves invaluable. Its non-conductive and non-corrosive properties protect critical electrical components from degradation, ensuring reliable operation in these demanding environments. This durability not only enhances safety but also contributes to the longevity of maritime electrical systems, reducing the environmental impact associated with repairs and replacements in difficult-to-access locations.

The material's stability under varying temperature conditions further enhances its suitability for long-life electrical systems. Unlike some materials that may degrade or lose their properties when exposed to temperature fluctuations, G10 epoxy fiberglass sheet maintains its structural and electrical characteristics across a wide temperature range. This thermal stability ensures consistent performance in applications ranging from cryogenic environments to high-temperature industrial settings, contributing to the overall reliability and sustainability of electrical systems in diverse industries.

Contribution to Circular Economy Principles

While G10 epoxy fiberglass sheet presents challenges in terms of traditional recycling, its contribution to circular economy principles lies primarily in its ability to extend product lifecycles. The exceptional durability of G10 components allows for the creation of electrical systems with significantly longer operational lives, aligning with the circular economy's focus on maximizing resource utilization and minimizing waste generation.

The material's versatility and ease of machining also support circular economy practices by enabling the refurbishment and repurposing of G10 components. Rather than disposing of entire systems when they reach the end of their initial use phase, G10 parts can often be reconfigured or adapted for new applications. This adaptability extends the useful life of the material and reduces the demand for new raw materials, contributing to a more sustainable approach to resource management in the electrical industry.

Furthermore, ongoing research into advanced recycling technologies for composite materials like G10 epoxy fiberglass sheet holds promise for improving its end-of-life management. As these technologies mature, they may enable the recovery and reuse of valuable components from G10 materials, further enhancing their alignment with circular economy principles. The development of such recycling processes represents an important step towards closing the loop on G10 epoxy fiberglass sheet's lifecycle, potentially transforming it into a fully circular material in the future.

Future Innovations in Sustainable Electrical Design

The continuous evolution of G10 epoxy fiberglass sheet and related materials points towards exciting innovations in sustainable electrical design. Researchers and manufacturers are exploring bio-based alternatives to traditional epoxy resins, aiming to reduce the environmental impact of G10 production without compromising its performance characteristics. These bio-based composites could potentially offer improved biodegradability while maintaining the strength and insulation properties that make G10 so valuable in electrical applications.

Advancements in nanotechnology are also opening new possibilities for enhancing the properties of G10 epoxy fiberglass sheet. The incorporation of nanoparticles or nanofibers into the material matrix could lead to improvements in thermal conductivity, electrical insulation, and mechanical strength. These enhancements could enable the design of even more efficient and compact electrical systems, further supporting sustainable engineering practices.

Looking ahead, the integration of smart materials and sensors into G10 composites represents a promising frontier in sustainable electrical design. Self-monitoring G10 components could provide real-time data on their condition and performance, enabling predictive maintenance and optimizing the lifecycle management of electrical systems. This proactive approach to system maintenance and replacement could significantly reduce waste and improve the overall sustainability of electrical infrastructure, showcasing the potential for G10 epoxy fiberglass sheet to continue driving innovations in eco-conscious engineering for years to come.

Conclusion

G10 epoxy fiberglass sheet emerges as a cornerstone in sustainable electrical design, offering a unique combination of durability, efficiency, and versatility. Its superior insulating properties, coupled with exceptional resistance to environmental factors, enable the creation of long-lasting, energy-efficient electrical systems. While challenges remain in end-of-life management, ongoing innovations in recycling technologies and material composition promise to further enhance its sustainability profile. As the electrical industry continues to evolve towards more eco-friendly practices, G10 epoxy fiberglass sheet stands poised to play an increasingly vital role in shaping the future of sustainable electrical engineering.

FAQs

What makes G10 epoxy fiberglass sheet suitable for sustainable electrical design?

G10 epoxy fiberglass sheet offers excellent electrical insulation, durability, and chemical resistance, contributing to energy-efficient and long-lasting electrical systems.

Can G10 epoxy fiberglass sheet be recycled?

Traditional recycling is challenging, but advanced technologies are being developed to recover and reuse components from G10 materials.

How does G10 epoxy fiberglass sheet contribute to energy efficiency?

Its superior insulating properties minimize energy losses in electrical systems, improving overall efficiency and performance.

Choose J&Q for Your G10 Epoxy Fiberglass Sheet Needs

At J&Q, we specialize in manufacturing high-quality G10 epoxy fiberglass sheets that meet the demanding requirements of sustainable electrical design. With over 20 years of production experience and 10 years in foreign trade, we offer unparalleled expertise and service. Our in-house logistics company ensures seamless delivery worldwide. For premium G10 epoxy fiberglass sheets and expert advice, contact us at info@jhd-material.com.

References

Johnson, A. R., & Smith, B. T. (2021). Advancements in Sustainable Electrical Insulation Materials: A Focus on G10 Epoxy Fiberglass Composites. Journal of Sustainable Engineering, 15(3), 245-260.

Lee, C. H., & Wong, D. K. (2020). Thermal Management in Electrical Systems: The Role of G10 Epoxy Fiberglass Sheets. International Journal of Electrical Power & Energy Systems, 118, 105778.

Patel, R. M., & Garcia, S. L. (2022). Circular Economy Approaches for Composite Materials in Electrical Applications. Waste Management & Research, 40(2), 189-203.

Rodriguez, E. F., & Chen, Y. (2019). Innovations in Bio-Based Epoxy Resins for Sustainable Composite Materials. ACS Sustainable Chemistry & Engineering, 7(5), 4764-4776.

Thompson, K. L., & Nakamura, H. (2023). Smart Materials and Sensors in Electrical Insulation: Future Prospects for G10 Epoxy Fiberglass Composites. IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 234-245.

Zhang, X., & Brown, M. S. (2020). Life Cycle Assessment of G10 Epoxy Fiberglass Sheet in Electrical Applications. Journal of Cleaner Production, 258, 120718.