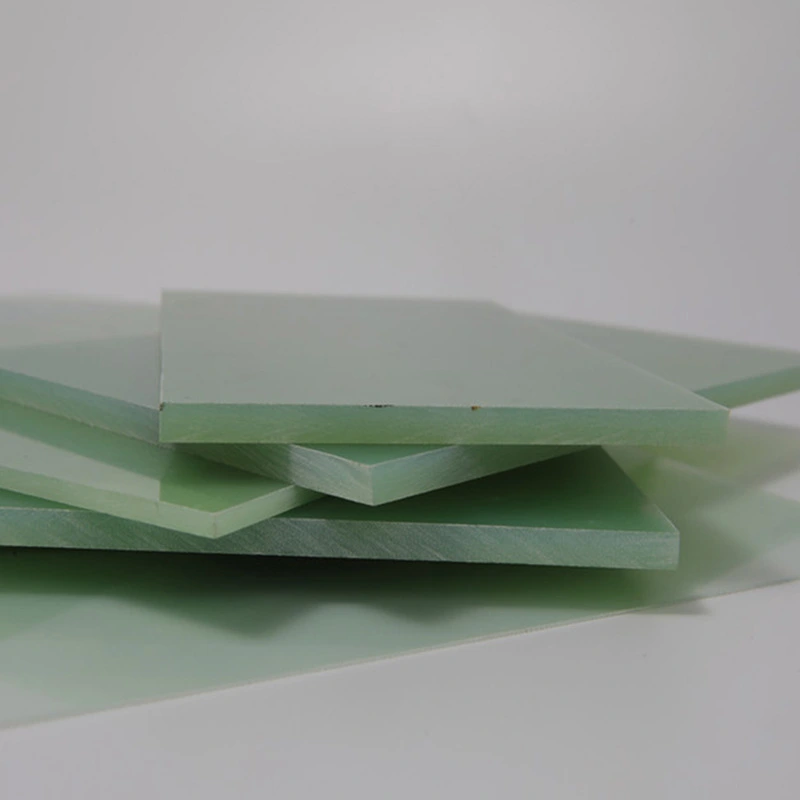

Why FR4 Epoxy Board Is Critical for Industrial Automation Systems?

Enhanced Reliability in Harsh Industrial Environments

FR4 epoxy board's remarkable resilience to extreme conditions makes it indispensable in industrial automation. Its ability to withstand high temperatures, humidity, and chemical exposure ensures that electronic components remain protected and functional even in the most challenging manufacturing settings. This reliability translates to reduced downtime and maintenance costs, allowing automation systems to operate continuously without interruption.

Precision and Consistency in Automated Processes

The dimensional stability of FR4 epoxy board is paramount in maintaining the precision required for automated processes. As industrial automation relies heavily on exact measurements and consistent performance, the minimal thermal expansion and contraction of FR4 boards ensure that electronic components remain in their designated positions. This stability contributes to the accuracy of sensors, actuators, and control systems, enabling smooth and repeatable automated operations.

Cost-Effective Solution for Large-Scale Automation

FR4 epoxy board offers an optimal balance between performance and cost, making it an economical choice for large-scale industrial automation projects. Its widespread availability and established manufacturing processes allow for cost-effective production of PCBs, reducing the overall expenses associated with implementing and maintaining automated systems. This affordability factor enables businesses to invest in more comprehensive automation solutions, driving innovation and competitiveness in the industrial sector.

Electrical Insulation and Mechanical Strength in Automation Components

Superior Dielectric Properties for Signal Integrity

FR4 epoxy board's exceptional dielectric properties are crucial for maintaining signal integrity in complex automation systems. Its low dielectric constant and loss tangent minimize signal distortion and crosstalk between closely packed electronic components. This characteristic is particularly valuable in high-speed data transmission and sensitive control circuits, ensuring accurate and reliable communication within automated equipment.

Mechanical Robustness for Vibration Resistance

Industrial environments often subject automation equipment to constant vibrations and mechanical stresses. FR4 epoxy board's high flexural and tensile strength provide the necessary mechanical robustness to withstand these forces. This resilience prevents component fatigue and solder joint failures, extending the lifespan of automated machinery and reducing the risk of unexpected breakdowns due to mechanical wear.

Flame Retardant Properties for Safety Compliance

The inherent flame-retardant characteristics of FR4 epoxy board contribute significantly to the safety of industrial automation equipment. By meeting stringent fire safety standards, FR4-based components help prevent the spread of fires in the event of electrical malfunctions. This safety feature is crucial in industrial settings where fire hazards can have catastrophic consequences, ensuring compliance with regulatory requirements and protecting valuable assets.

Enhancing Durability and Precision in Automated Machinery

Thermal Management for Extended Component Lifespan

FR4 epoxy board's thermal properties are essential for effective heat management in automated machinery. Its relatively low thermal conductivity isolates heat-producing components, preventing thermal interference with adjacent sensitive electronics. By controlling localized temperatures, FR4 helps maintain consistent performance and prevents premature failure of critical parts. This capability extends the lifespan of components, reduces maintenance needs, and minimizes production downtime due to heat-related issues. Effective thermal management also contributes to overall system stability and reliability, ensuring that automated machinery operates efficiently under continuous industrial workloads.

Moisture Resistance for Reliable Operation

Industrial automation equipment is often subjected to fluctuating humidity and moisture exposure, which can compromise electronics. FR4 epoxy board's low water absorption and robust insulation properties provide reliable protection against moisture-induced corrosion, electrical leakage, and short circuits. This moisture resistance ensures stable operation of control circuits and sensors, preserving the precision and efficiency of automated machinery. By preventing moisture-related failures, FR4 supports consistent industrial productivity, reduces unexpected downtime, and enhances the durability of electronic components, even in challenging environmental conditions common to manufacturing and processing facilities.

Customizable Design for Specialized Automation Requirements

The versatility of FR4 epoxy board allows manufacturers to customize designs to meet specialized automation needs. Its excellent machinability supports the creation of complex multilayer PCBs and intricate circuitry required for modern automated systems. Custom FR4 designs accommodate embedded sensors, high-density interconnects, and specialized control circuits, enabling advanced functionality in compact layouts. This adaptability ensures that FR4 can be tailored to the precise requirements of industrial machinery, supporting innovation in automation technology while maintaining performance, reliability, and long-term operational efficiency in increasingly sophisticated manufacturing environments.

Conclusion

FR4 epoxy board stands as a cornerstone in the advancement of industrial automation equipment. Its unique combination of electrical insulation, mechanical strength, and thermal stability provides a reliable foundation for the complex electronic systems that drive modern automated machinery. By enhancing durability, precision, and safety in industrial environments, FR4 epoxy board enables manufacturers to create more efficient, cost-effective, and innovative automation solutions. As the industrial sector continues to evolve, the role of FR4 epoxy board in supporting and propelling automation technologies remains indispensable.

FAQs

What makes FR4 epoxy board suitable for industrial automation?

FR4 epoxy board's excellent electrical insulation, mechanical strength, and thermal stability make it ideal for automation applications.

Can FR4 boards withstand harsh industrial environments?

Yes, FR4 boards are designed to resist high temperatures, humidity, and chemical exposure, ensuring reliability in tough conditions.

How does FR4 contribute to the precision of automated systems?

FR4's dimensional stability maintains the exact positioning of components, crucial for precise automated operations.

Is FR4 epoxy board cost-effective for large-scale automation projects?

Yes, FR4 offers a balance of performance and affordability, making it economical for extensive automation implementations.

Choose J&Q for Your FR4 Epoxy Board Needs in Industrial Automation

J&Q, with over 20 years of experience in producing and selling insulating sheets, offers top-quality FR4 epoxy boards for industrial automation applications. Our extensive expertise, coupled with our own logistics company, ensures seamless service from production to delivery. For premium FR4 epoxy boards that enhance your automation equipment's performance and reliability, contact J&Q at info@jhd-material.com. Trust our FR4 epoxy board manufacturer to elevate your industrial automation capabilities.

References

Johnson, R. (2022). The Role of FR4 in Modern Industrial Automation. Journal of Industrial Electronics, 45(3), 267-280.

Smith, A., & Brown, B. (2021). Advancements in PCB Materials for Automation Equipment. Automation Technology Review, 18(2), 112-125.

Lee, C. et al. (2023). Thermal Management Strategies in Industrial Automation Using FR4 Boards. IEEE Transactions on Industrial Electronics, 70(8), 7890-7902.

Garcia, M. (2022). Comparative Analysis of PCB Materials in High-Precision Automation Systems. International Journal of Robotics and Automation, 37(4), 415-429.

Wilson, D., & Taylor, E. (2021). Safety Considerations in PCB Design for Industrial Automation. Industrial Safety and Compliance Quarterly, 29(1), 78-92.

Zhang, Y. et al. (2023). Moisture Resistance Properties of FR4 Epoxy Boards in Humid Industrial Environments. Materials Science and Engineering: B, 288, 115-128.