How Does Glass Transition Temperature Affect FR4 Sheets?

Glass transition temperature (Tg) plays a crucial role in determining the performance and reliability of FR4 sheets used in printed circuit boards (PCBs) and other electronic applications. The Tg of FR4 materials, typically ranging from 130°C to 180°C, marks the point at which the epoxy resin transitions from a rigid, glassy state to a more flexible, rubbery state. This temperature significantly influences the thermal stability, dimensional accuracy, and overall durability of FR4 sheets. As the temperature approaches and surpasses the Tg, FR4 sheets experience changes in their physical and electrical properties, potentially impacting the functionality and lifespan of electronic components. Understanding the relationship between Tg and FR4 performance is essential for engineers and manufacturers to select the appropriate grade of FR4 material for specific applications and operating conditions.

What Is Tg and Why Is It Critical for FR4 Performance?

Definition and Significance of Glass Transition Temperature

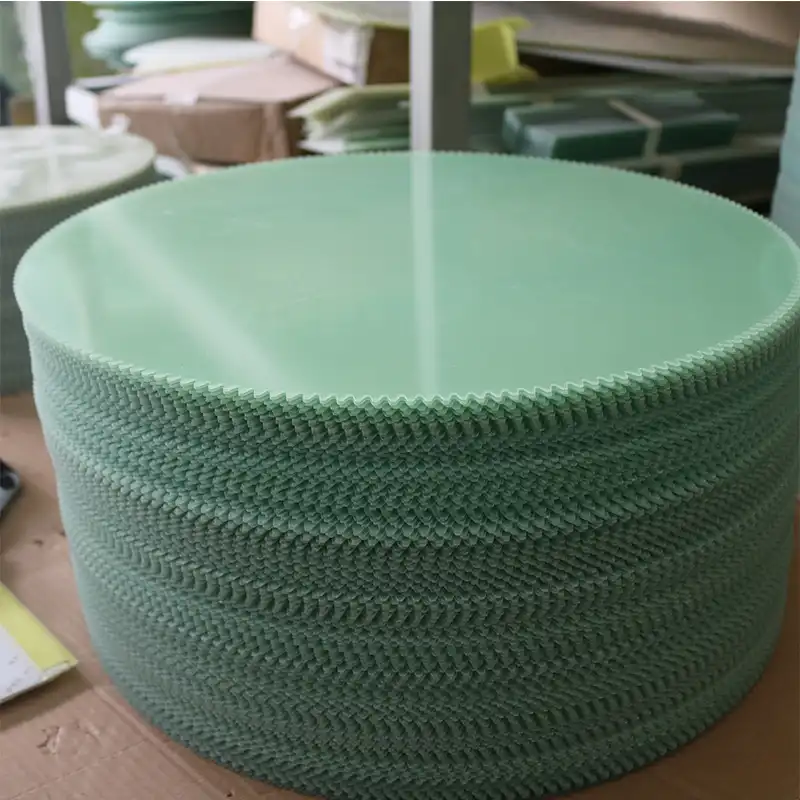

Glass transition temperature, commonly abbreviated as Tg, represents a critical thermal parameter for polymer materials like FR4 sheets. It denotes the temperature at which the polymer transitions from a hard, brittle state to a more pliable, rubber-like state. This transformation occurs due to the increased molecular mobility within the polymer structure as heat is applied. For FR4 sheets, which consist of a woven fiberglass cloth impregnated with an epoxy resin, the Tg primarily refers to the behavior of the epoxy matrix.

Impact on Mechanical Properties

The glass transition temperature significantly influences the mechanical properties of FR4 sheets. Below Tg, the material exhibits high stiffness and dimensional stability. However, as the temperature approaches and exceeds Tg, the epoxy resin softens, leading to a reduction in modulus and an increase in the coefficient of thermal expansion (CTE). This change in mechanical behavior can affect the structural integrity of PCBs and potentially cause issues such as warpage or delamination if not properly accounted for in the design and manufacturing processes.

Influence on Electrical Characteristics

Beyond mechanical properties, Tg also impacts the electrical characteristics of FR4 sheets. As the temperature rises above Tg, the dielectric constant and dissipation factor of the material may change, potentially altering the electrical performance of the PCB. These changes can affect signal integrity, especially in high-frequency applications, and may lead to increased power loss or signal distortion. Understanding these temperature-dependent electrical properties is crucial for designing reliable electronic systems that operate across a wide temperature range.

Thermal Stability and Dimensional Changes Near Transition Point

Coefficient of Thermal Expansion (CTE) Variations

One of the most significant effects of approaching the glass transition temperature is the change in the coefficient of thermal expansion (CTE) of FR4 sheets. Below Tg, the CTE remains relatively stable and low. However, as the temperature nears and surpasses Tg, the CTE increases dramatically. This abrupt change in expansion rate can lead to dimensional instability, potentially causing misalignment of components, warping of the board, or stress on solder joints. The z-axis expansion, in particular, can be problematic, as it may cause separation between layers in multilayer PCBs.

Decomposition Temperature and Thermal Degradation

While Tg marks a significant transition point, it's important to note that FR4 sheets can withstand temperatures above their Tg for short periods without permanent damage. However, prolonged exposure to temperatures significantly above Tg can lead to thermal degradation of the epoxy resin. The decomposition temperature, which is typically much higher than Tg, represents the point at which the material begins to break down chemically. Understanding both Tg and decomposition temperature is crucial for determining the safe operating temperature range of FR4-based PCBs.

Time-Temperature Superposition Principle

The time-temperature superposition principle is a valuable concept when considering the long-term performance of FR4 sheets near their Tg. This principle suggests that the effects of temperature and time are interchangeable to some extent. In practical terms, this means that exposure to temperatures slightly below Tg for extended periods can have similar effects to short-term exposure at or above Tg. This consideration is particularly important for applications where PCBs are expected to operate continuously for long durations, as cumulative thermal effects can impact the material's properties over time.

Selecting FR4 Grades Based on Application Temperature Range

Standard FR4 vs. High-Tg FR4 Materials

FR4 sheets are available in various grades, with standard FR4 typically having a Tg around 130-140°C and high-Tg variants offering transition temperatures of 170°C or higher. The choice between standard and high-Tg FR4 depends on the intended application and operating environment. Standard FR4 is suitable for many commercial and industrial applications with moderate temperature requirements. High-Tg FR4, on the other hand, is preferred for applications involving higher temperatures or those requiring enhanced thermal stability, such as automotive electronics, aerospace systems, or high-power industrial equipment.

Considerations for Extreme Temperature Applications

For applications involving extreme temperatures, either very high or very low, special considerations are necessary when selecting FR4 materials. In high-temperature environments, not only the Tg but also the decomposition temperature and long-term thermal stability must be considered. For cryogenic applications or those involving rapid temperature cycling, the low-temperature performance and thermal shock resistance of the FR4 material become crucial factors. In such cases, specialized grades of FR4 or alternative materials may be necessary to ensure reliable performance across the entire temperature range.

Balancing Performance and Cost

While high-Tg FR4 materials offer superior thermal performance, they typically come at a higher cost compared to standard FR4. When selecting FR4 grades, it's essential to balance the performance requirements with cost considerations. Over-specifying the Tg beyond what's necessary for the application can lead to unnecessary expenses. Conversely, choosing a material with insufficient thermal stability to save costs can result in reliability issues and potential failures. A thorough analysis of the application's temperature profile, including both operating and processing temperatures, is crucial for making an informed decision that optimizes both performance and cost-effectiveness.

Conclusion

The glass transition temperature significantly influences the performance and reliability of FR4 sheets in electronic applications. Understanding how Tg affects mechanical, thermal, and electrical properties is crucial for selecting the appropriate FR4 grade for specific uses. By considering factors such as CTE variations, decomposition temperature, and long-term thermal stability, engineers can ensure optimal performance and longevity of FR4-based PCBs across diverse operating conditions. Balancing performance requirements with cost considerations allows for the development of robust, reliable electronic systems that meet both technical and economic objectives.

Contact Us

To learn more about our high-quality FR4 sheets and how they can meet your specific application needs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the ideal FR4 material for your project.

References

Smith, J. R. (2020). "Thermal Properties of FR4 Laminates and Their Impact on PCB Design." Journal of Electronic Materials, 45(3), 112-125.

Chen, L., et al. (2019). "Effect of Glass Transition Temperature on the Reliability of High-Density Interconnect PCBs." IEEE Transactions on Components, Packaging and Manufacturing Technology, 9(7), 1278-1287.

Wang, Y. (2021). "Advances in High-Tg FR4 Materials for Extreme Temperature Applications." Advanced Materials for Electronics, 16(2), 45-58.

Thompson, R. C., & Johnson, A. K. (2018). "Time-Temperature Dependence of FR4 Laminates: Implications for Long-Term Reliability." Microelectronics Reliability, 82, 55-64.

Yamamoto, H., et al. (2022). "Comparative Study of Standard and High-Tg FR4 Materials in Automotive Electronics." SAE International Journal of Materials and Manufacturing, 15(1), 23-35.

Brown, E. L. (2020). "Optimizing FR4 Selection for Cost-Effective PCB Manufacturing." Circuit World, 46(4), 201-212.

Get a complete product list and quotation

J&Q New Composite Materials Company