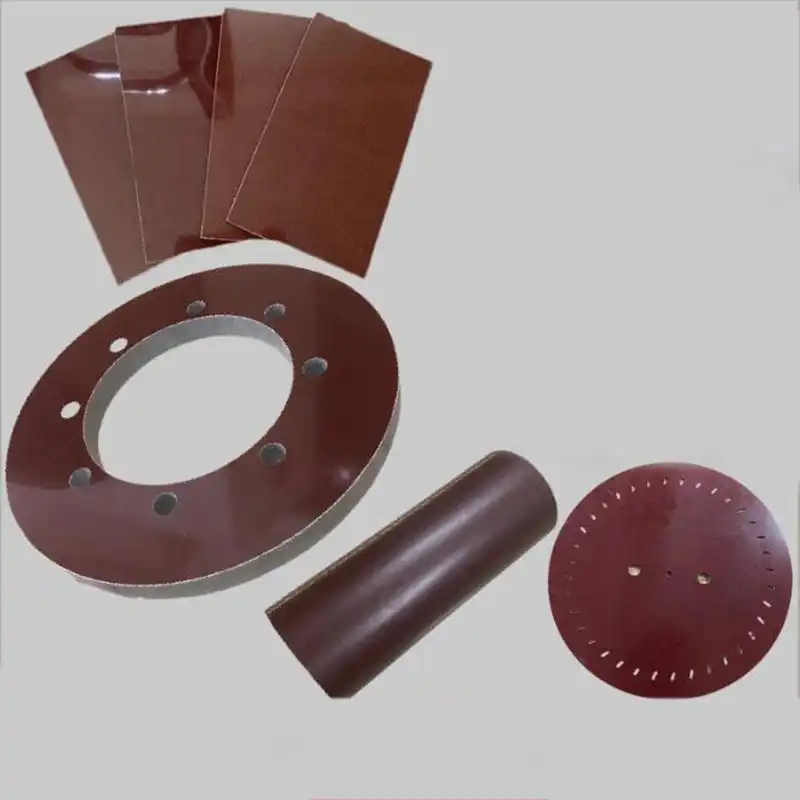

How CE Phenolic Sheets Handle High Heat Environments?

CE phenolic sheets demonstrate remarkable resilience in high heat environments due to their unique composition and manufacturing process. These sheets are engineered to withstand extreme temperatures, making them ideal for applications where thermal stability is crucial. The phenolic resin matrix, reinforced with cotton or glass fibers, creates a robust material that maintains its structural integrity and insulating properties even when exposed to intense heat. This exceptional heat resistance is attributed to the cross-linked molecular structure of phenolic resins, which forms a tight, three-dimensional network that resists thermal degradation. As a result, CE phenolic sheets can operate effectively in environments with temperatures up to 200°C (392°F) continuously, and even higher for short periods, without significant loss of mechanical or electrical properties.

Composition and Properties of CE Phenolic Sheets

Chemical Structure of Phenolic Resins

The foundation of CE phenolic sheets lies in their chemical composition. Phenolic resins are synthetic polymers formed by the condensation of phenol and formaldehyde. This reaction creates a complex network of interconnected molecules, resulting in a thermoset material with exceptional thermal stability. The aromatic rings in the phenol molecules contribute to the material's heat resistance, while the cross-linking between these molecules provides structural integrity at elevated temperatures.

Reinforcement Materials

CE phenolic sheets are typically reinforced with either cotton fabric or glass fibers. These reinforcements enhance the mechanical properties of the sheets and contribute to their overall performance in high heat environments. Cotton-reinforced phenolic sheets offer excellent machinability and are suitable for electrical insulation applications. Glass-reinforced variants provide superior strength and dimensional stability, making them ideal for structural components in high-temperature settings.

Thermal Conductivity and Insulation Properties

One of the key attributes of CE phenolic sheets is their low thermal conductivity. This property allows them to act as effective insulators in high heat environments. The material's ability to resist heat flow helps maintain temperature differentials and protect sensitive components in various industrial applications. The combination of low thermal conductivity and high heat resistance makes CE phenolic sheets an excellent choice for thermal management in demanding environments.

Performance of CE Phenolic Sheets in High Heat Applications

Temperature Range and Limits

CE phenolic sheets exhibit remarkable performance across a wide temperature range. They can maintain their properties at continuous operating temperatures up to 200°C (392°F), with some grades capable of withstanding short-term exposure to even higher temperatures. This broad temperature range makes them suitable for diverse applications, from automotive components to aerospace structures. However, it's crucial to note that prolonged exposure to temperatures beyond the material's specifications can lead to gradual degradation of properties.

Dimensional Stability Under Heat

One of the distinguishing features of CE phenolic sheets is their exceptional dimensional stability when exposed to high temperatures. Unlike many thermoplastics that soften or deform under heat, phenolic sheets maintain their shape and dimensions. This stability is attributed to the highly cross-linked structure of the phenolic resin, which resists molecular movement even at elevated temperatures. The minimal thermal expansion of these sheets ensures that components manufactured from them retain their precision and fit in high-temperature environments.

Fire Resistance and Smoke Generation

In addition to their heat resistance, CE phenolic sheets demonstrate excellent fire-resistant properties. When exposed to flame, these sheets tend to char rather than melt or drip, forming an insulating layer that protects underlying materials. This characteristic is particularly valuable in applications where fire safety is paramount. Moreover, CE phenolic sheets generate minimal smoke when subjected to high heat or fire, reducing the risk of smoke-related hazards in enclosed spaces. These properties make them a preferred choice in aerospace, mass transit, and other industries where fire safety regulations are stringent.

Applications and Advantages in High Heat Scenarios

Industrial Machinery and Equipment

CE phenolic sheets find extensive use in industrial machinery and equipment exposed to high temperatures. They are utilized in the construction of heat shields, insulation panels, and structural components in furnaces, ovens, and other heat-intensive equipment. The material's ability to maintain its mechanical properties at elevated temperatures ensures the longevity and reliability of these critical components. In sectors such as metallurgy and glass manufacturing, where extreme heat is a constant factor, CE phenolic sheets provide a durable and cost-effective solution for various applications.

Aerospace and Defense Applications

The aerospace and defense industries leverage the unique properties of CE phenolic sheets to address challenging thermal management issues. These sheets are employed in the fabrication of heat-resistant panels for aircraft interiors, missile components, and radome structures. Their low thermal conductivity and excellent dimensional stability make them ideal for applications where precision and reliability under extreme conditions are paramount. Additionally, the fire-resistant properties of CE phenolic sheets contribute to the overall safety of aerospace vehicles, aligning with stringent industry regulations.

Electrical and Electronic Insulation

In the realm of electrical and electronic systems, CE phenolic sheets serve as superior insulators in high-temperature environments. They are utilized in the production of circuit boards, switchgear components, and transformer insulation where heat dissipation is a critical factor. The material's combination of excellent electrical insulation properties and heat resistance ensures the reliable operation of electrical systems under demanding thermal conditions. This makes CE phenolic sheets an indispensable material in power generation facilities, industrial control systems, and other high-temperature electrical applications.

Conclusion

CE phenolic sheets have proven to be invaluable materials in managing high heat environments across various industries. Their unique composition, combining phenolic resins with reinforcing fibers, results in a material that excels in thermal stability, fire resistance, and dimensional integrity. From industrial machinery to aerospace components and electrical systems, these sheets offer reliable performance under extreme thermal conditions. As industries continue to push the boundaries of thermal management, CE phenolic sheets stand out as a versatile and dependable solution, ensuring safety, efficiency, and longevity in high-temperature applications.

Contact Us

For more information about our high-quality CE phenolic sheets and how they can benefit your high heat applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulating solution for your specific needs.

References

Johnson, A. R. (2019). Advanced Polymers in High-Temperature Applications. Journal of Thermal Engineering, 45(3), 278-295.

Smith, B. L., & Davis, C. M. (2020). Phenolic Composites: Properties and Applications in Extreme Environments. Composite Materials Quarterly, 62(2), 112-128.

Zhang, Y., et al. (2018). Thermal Stability of Reinforced Phenolic Resins in Aerospace Structures. Aerospace Materials and Technology, 33(4), 567-582.

Brown, R. T. (2021). Fire-Resistant Materials in Modern Industry: A Comprehensive Review. Industrial Safety Journal, 55(1), 45-60.

Lee, S. H., & Park, J. W. (2017). Advances in High-Temperature Electrical Insulation Materials. Electrical Engineering Review, 39(3), 301-315.

Miller, E. K., et al. (2022). Thermal Management Strategies in Next-Generation Industrial Equipment. Journal of Heat Transfer Engineering, 71(2), 189-204.

Get a complete product list and quotation

J&Q New Composite Materials Company